Improved belt-type concentration squeezing filtering machine

A technology of thickening press and filter, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of inconsistent movement of the front and rear tensioning cylinders, unclean washing filter cloth, easy deviation of belt filter cloth, etc. To achieve the effect of good sewage discharge, convenient and easy operation, and reduce the number of damages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

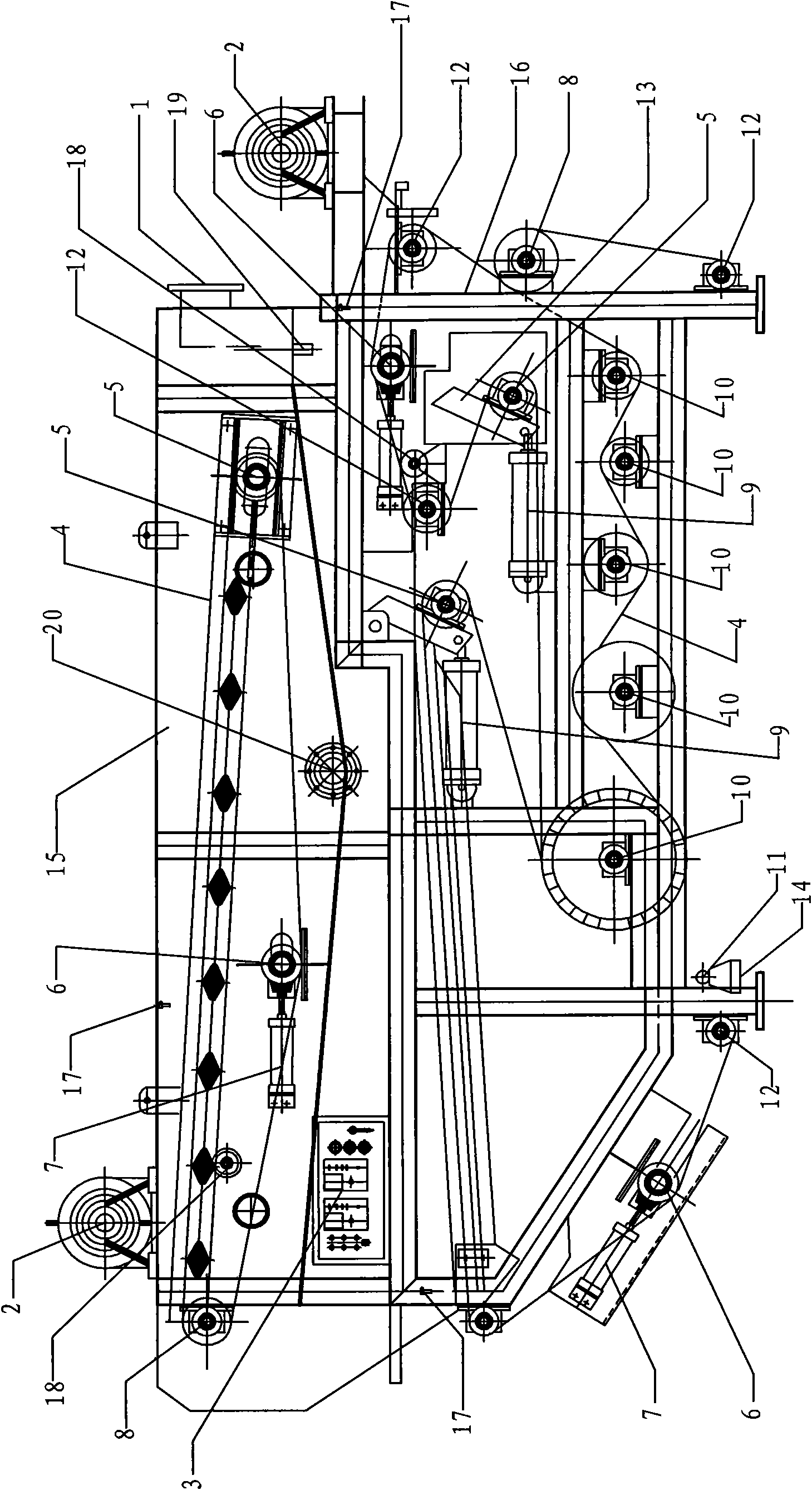

[0011] Such as figure 1 As shown, the present invention includes a belt-type thickening section, a filter press section, a filter cloth rectifying device, a filter cloth cleaning device, a filter cloth tensioning device, a reduction motor 2 and an electric control box 3, and the belt-type thickening section includes a feed pipe 1, Water inlet pipe 18, sewage pipe 19, drain pipe 20, strip filter cloth 4, tension roller 5, deviation roller 6, deviation cylinder 7 and drive roller 8, the filter press section includes strip filter cloth 4, tension cylinder 9. Tension roller 5, press roller 10, deviation roller 6, water spray pipe 11, water inlet pipe 18, deviation cylinder 7 and dehydration roller 12, and the two tension cylinders 9 before and after the filter press section are connected with movable Shaft 13, the water spray pipe 11 is arranged beside the dewatering roller 12 at the lower part of the front section of the filter press section, and a water bucket 14 for reverse wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com