Centrifugal pump with free flow wheel

A centrifugal pump and working wheel technology, applied in the field of centrifugal pumps, can solve the problems of high processing costs, achieve the effect of preventing pump failure and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

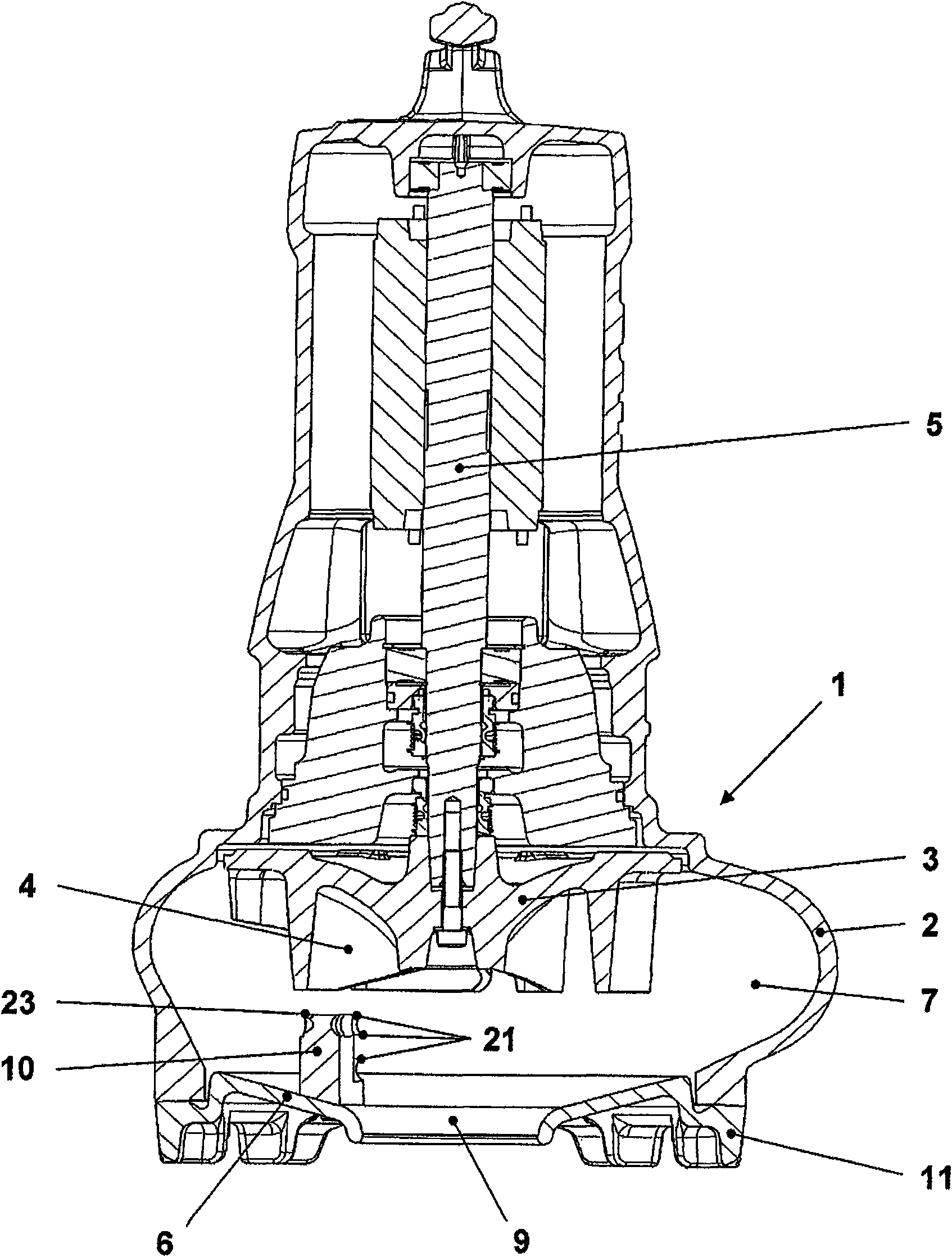

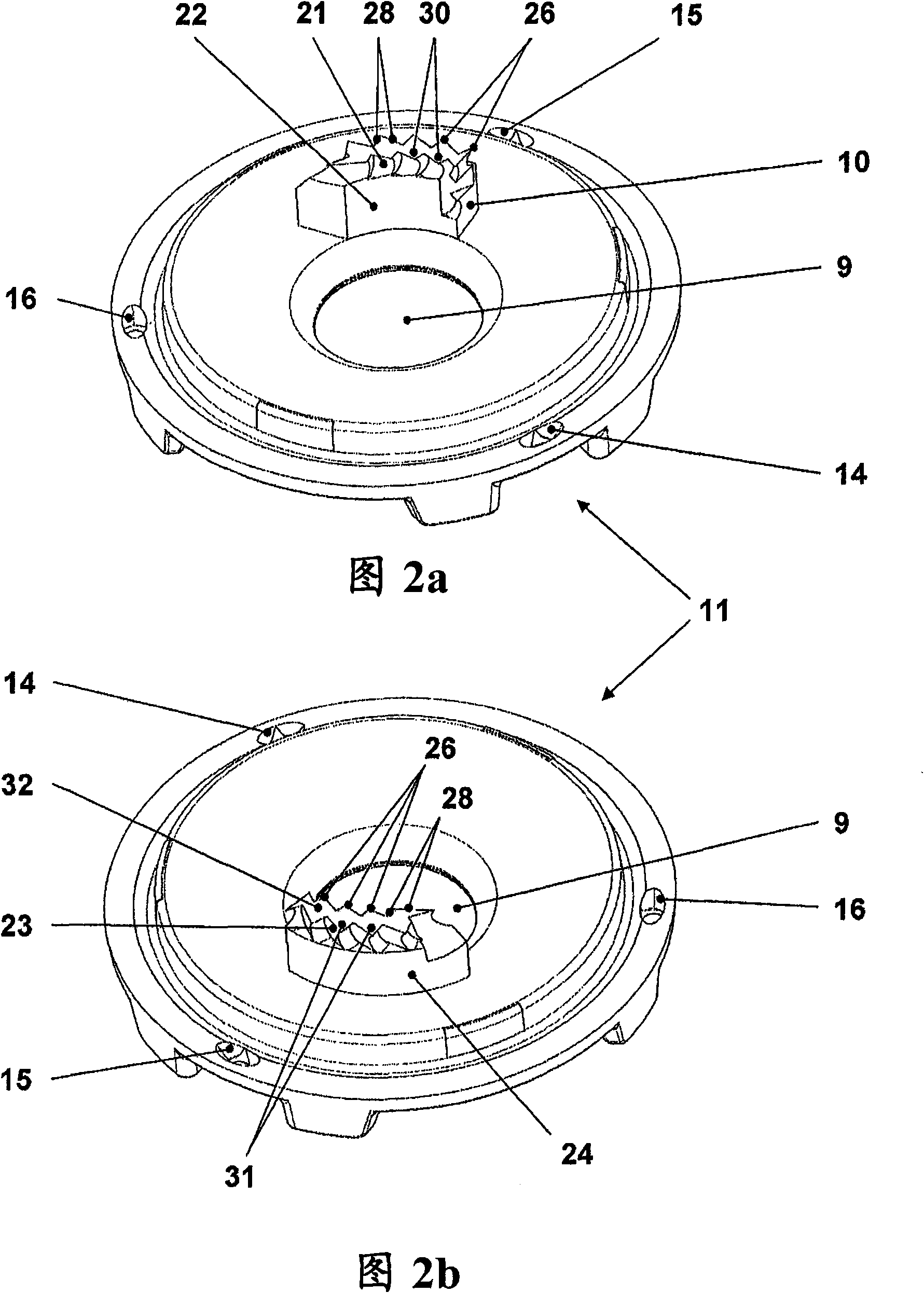

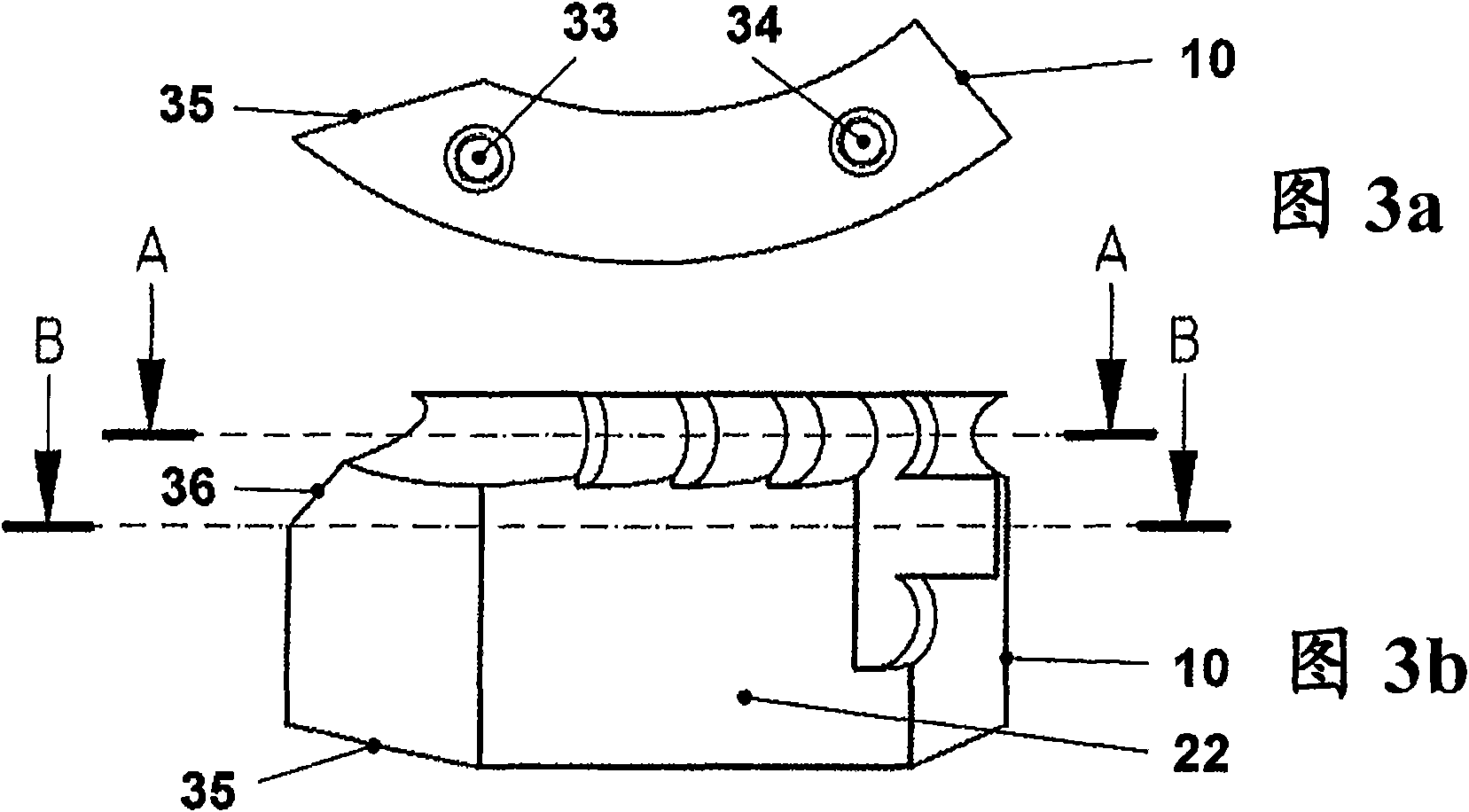

[0022] figure 1 A centrifugal pump 1 is shown for conveying conveying liquids mixed with conveying components which tend to form sticks. The centrifugal pump 1 has a non-clogging impeller 3 arranged rotatably in a housing 2 , which has impeller blades 4 , which is connected to a drive shaft 5 . A vane-free space 7 is arranged between the suction-side housing wall 6 and the unclogged impeller 3 . The centrifugal pump 1 can be connected to the line by means of a pressure connection (not shown). The delivery liquid flows to the pump through the suction hole 9 and a suction line (not shown) can also be connected to this suction hole. A fluid-influencing device 10 is arranged on the suction-side housing wall 6 opposite the impeller blades 4 . Here, in this exemplary embodiment, the predominant part of the suction-side housing wall 6 is formed by a removable suction-side housing cover 11 , where the fluid-influencing device 10 is formed in one piece with the The housing cover is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com