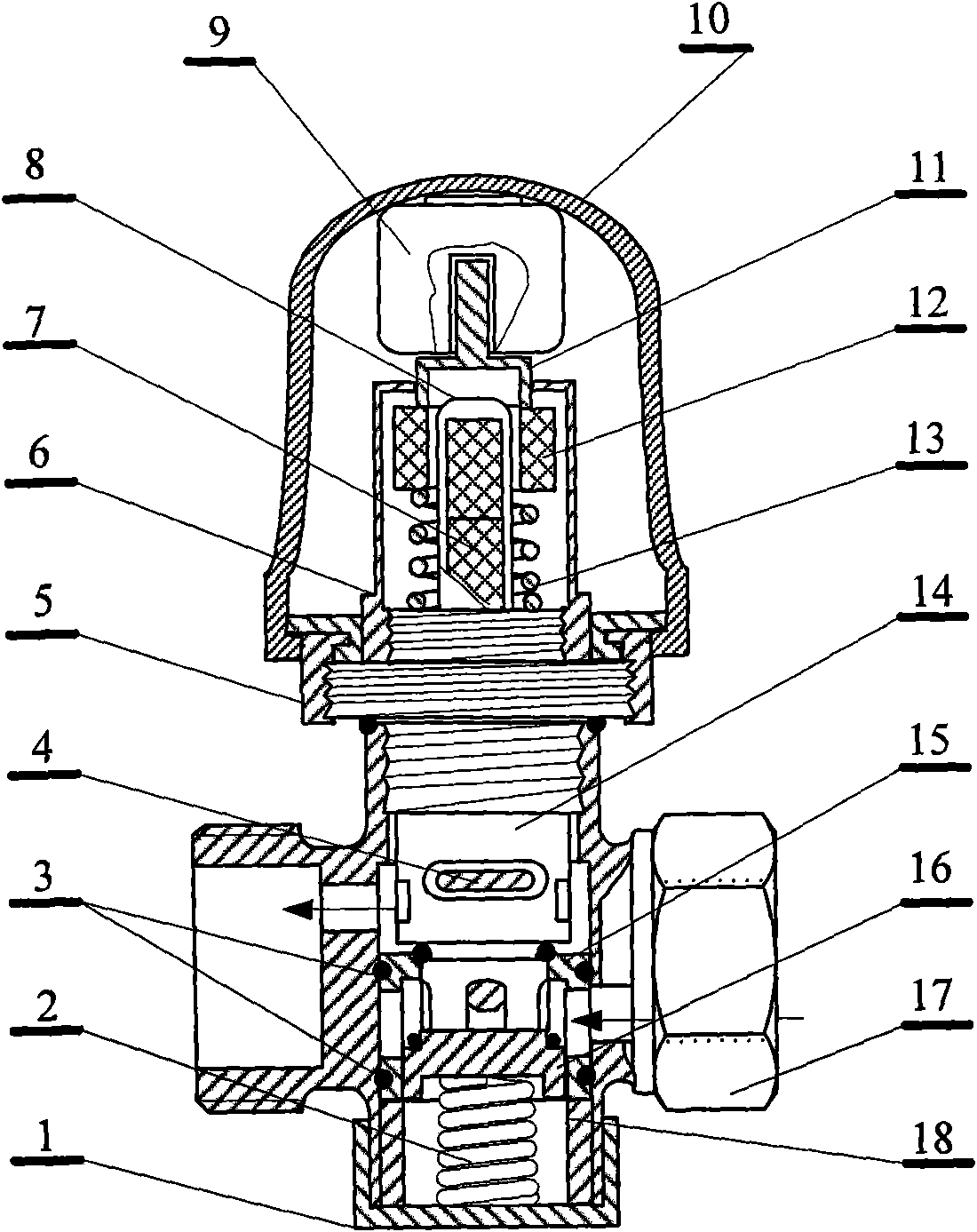

Temperature controlling valve with function of cleaning valve core

A technology of temperature control valve and cleaning valve, which is applied in the direction of valve operation/release device, valve lift, valve details, etc. It can solve problems such as temperature control failure, difficulty in valve opening and closing, and inability to clean online, so as to achieve effective control and effective cleaning. The effect of room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

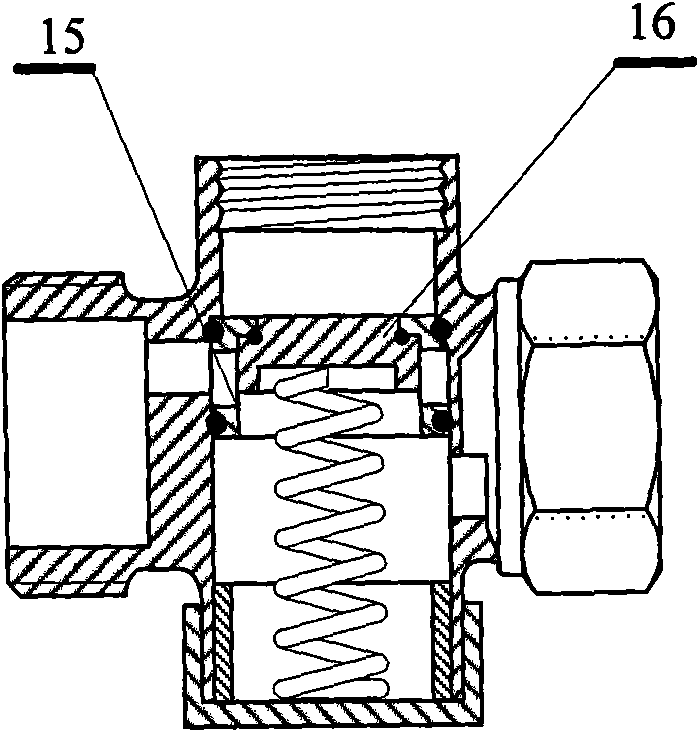

[0009] The specific embodiment of the present invention adopts the temperature sensor (9) of temperature bulb type. When the spool (14) is not blocked by foreign matter in the medium and works normally, such as when the indoor temperature is lower than the set value of the valve, the bellows in the temperature sensor (9) is not compressed, due to the return spring (13 ), the magnetic ring (12) and the linkage (11) are at a higher position, and due to the magnetic coupling effect, the magnetic ring (12) connects the valve core of the inner magnetic column (7) in the valve core sleeve (8) The column is lifted to a higher position, and the spool column drives the large piston (4) to leave the water inlet at the inner bottom of the spool (14); since the spool (14) is connected to the top of the valve body (17) by threads, the spool (14) ) bottom through the upper small piston (15), press the lower small piston (16) on the positioning ring (18), and at the same time compress the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com