Water-saving closed type cooling tower

A closed cooling tower and water-saving technology, which is applied in the field of closed cooling towers and water-saving closed cooling towers, can solve the problems of high equipment cost, large floor area, and water evaporation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

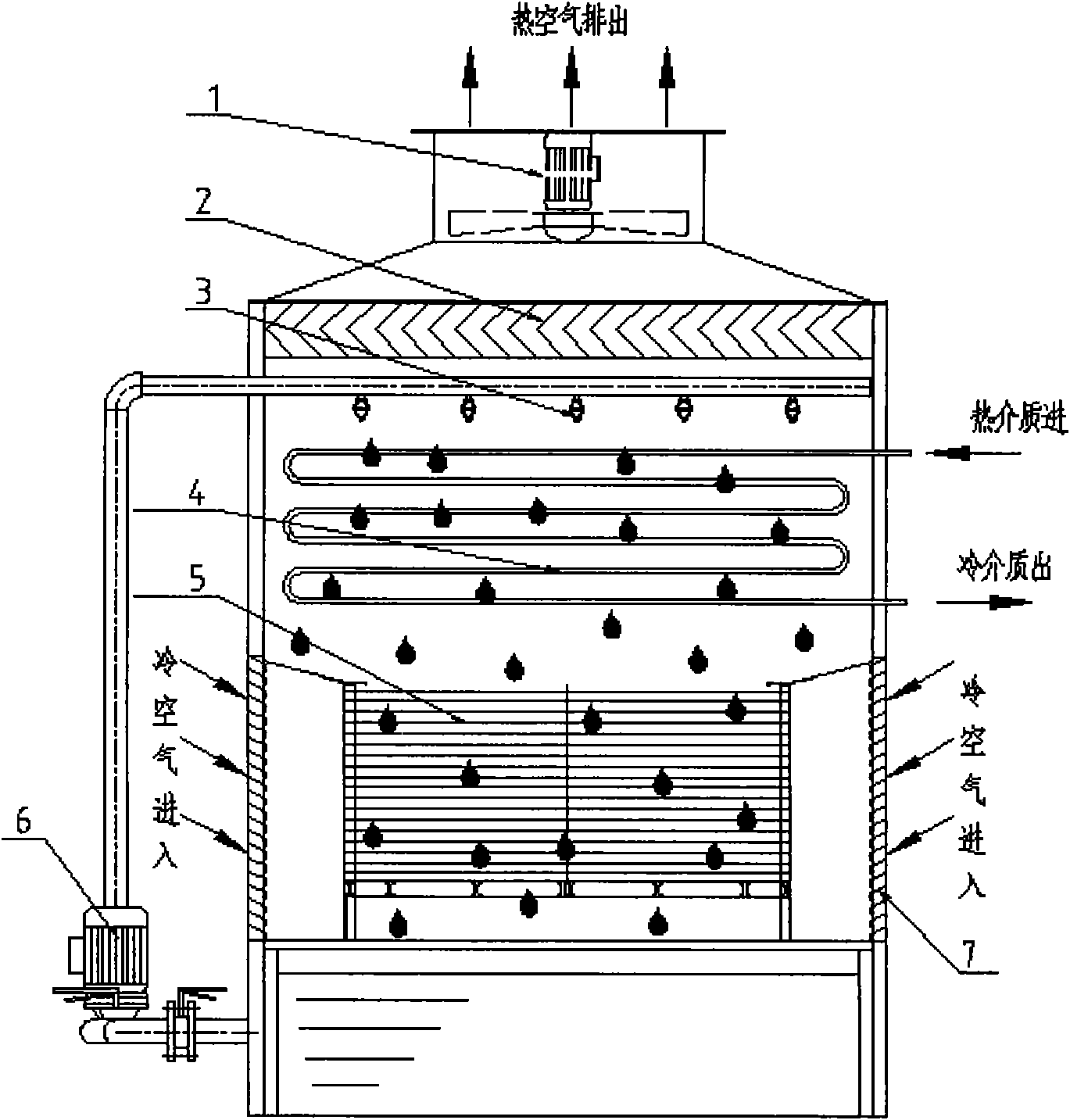

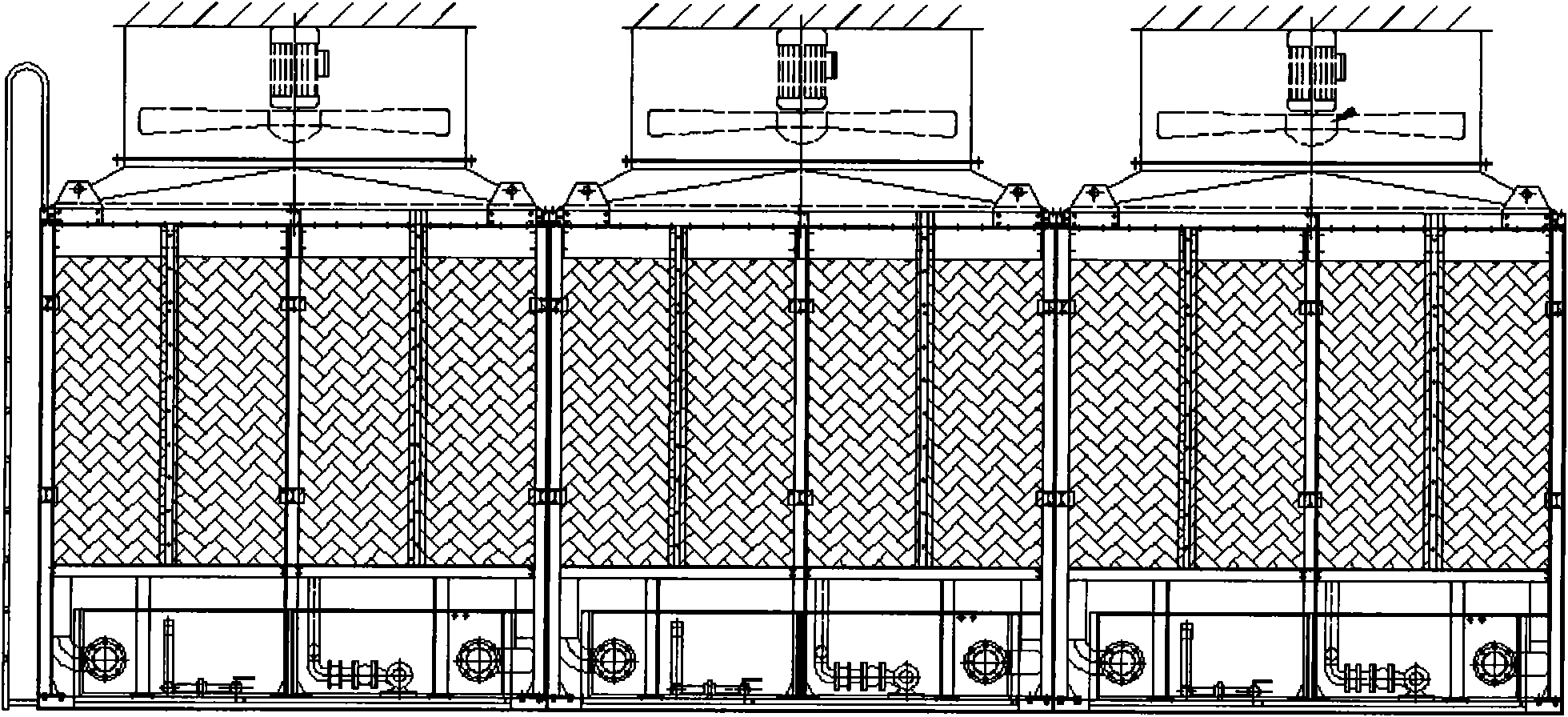

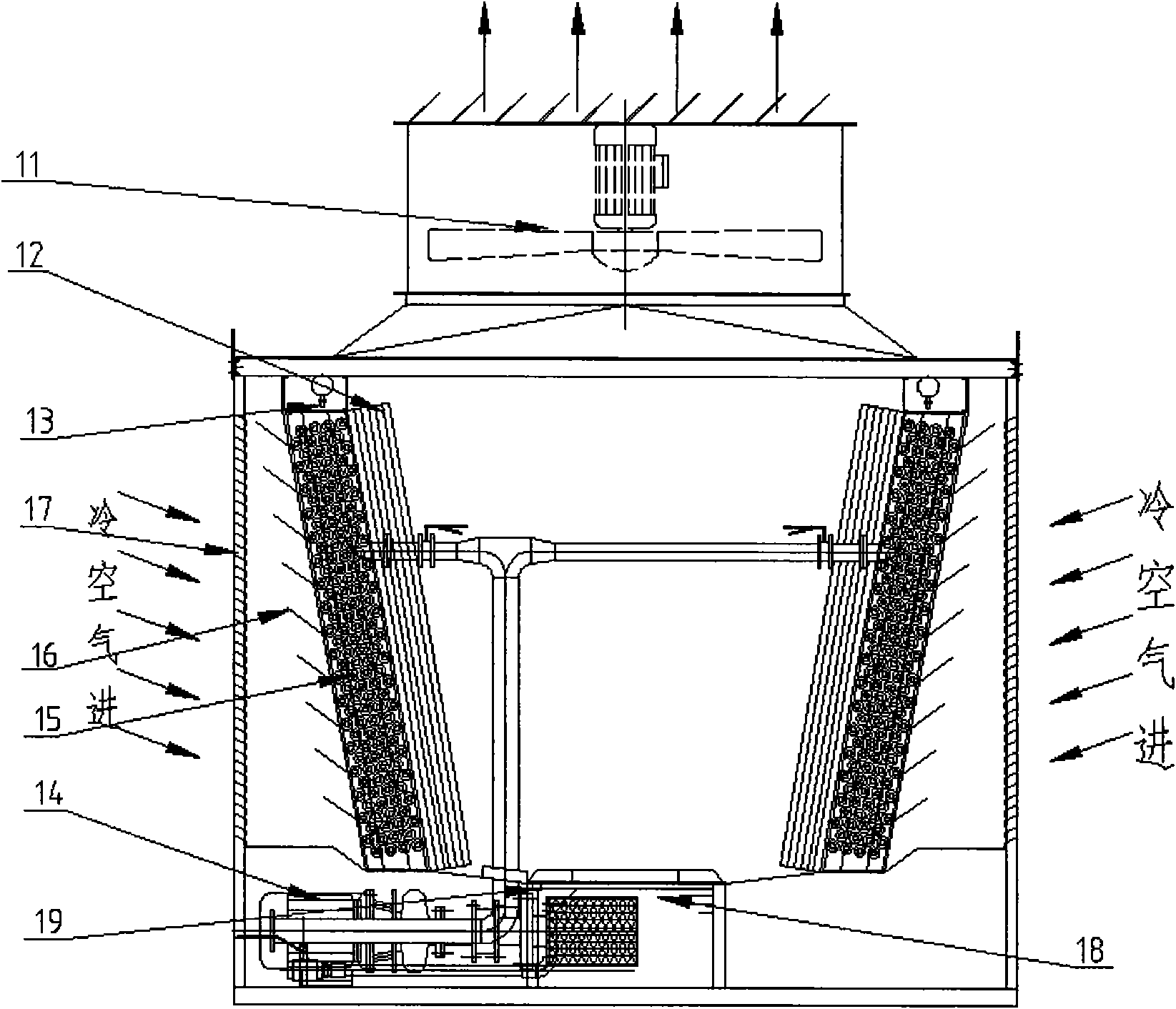

[0020] The water-saving closed cooling tower of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] figure 2 Shows the front view of the water-saving closed circuit cooling tower of the present invention, image 3 A side sectional view of the water-saving closed circuit cooling tower of the present invention is shown. As shown in the figure, the closed cooling tower of the present invention includes fan (with non-return louver) 11, water eliminator 12, nozzle 13, air cooling tube group 14, spray pump 15, louver 16, air inlet grille 17, Main components such as the lower sump 18 and the replenishment valve 19. Wherein, in the closed cooling tower of the present invention, the two groups of air-cooling tube groups 14 located below the nozzles 13 on both sides are arranged obliquely, and the inclination angle varies with the wind speed, and is generally 10-20 degrees from the vertical direction. The purpose of the inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com