A Check Calculation Method for Mixed Flow Closed Cooling Tower

A technology of closed cooling tower and calculation method, applied in the direction of water shower cooler, computer-aided design, heat exchanger type, etc., can solve the problems of substandard cooling effect, waste of resources, large amount of consumables, etc., and improve recycling efficiency, reduce industrial water consumption, and save operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

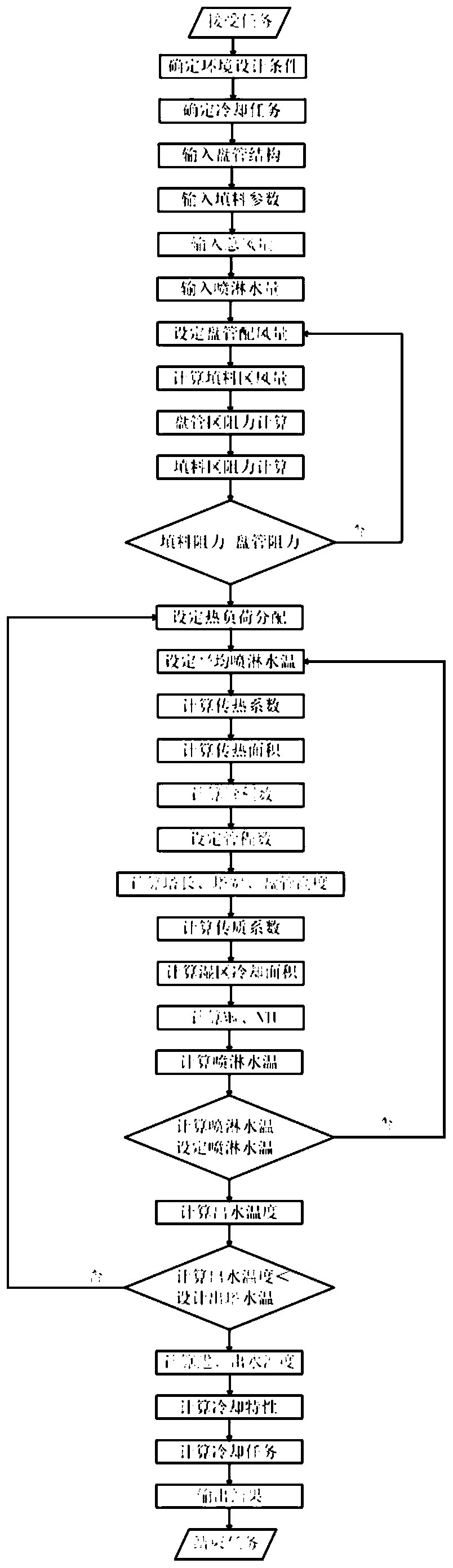

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1. Environmental meteorological conditions: dry bulb temperature θ31.5°C, wet bulb temperature τ28°C, atmospheric pressure: 99.4kPa.

[0055] Determine the cooling task: single tower cooling water Q100m 3 / h, inlet water temperature T 1 40°C, outlet water temperature T 2 is 35°C.

[0056] Input the structural size of the coil, select stainless steel, heat exchange tube specifications: tube diameter 16mm, wall thickness 0.8mm, center distance of each row of tubes 0.032m, longitudinal tube center distance 0.07m, coil length 3.2m, 4 layers of tubes per pass , the number of tubes is 4, and each layer has 39 / 40 tubes. The flow velocity in the pipe is 1.07m / s, which is within a reasonable range.

[0057] The input packing type is trapezoidal ramp wave, the size length is 3.2m, the height is 1.8m, and the depth is 1.3m.

[0058] Design total air volume 89000m 3 / h. Spray water flow 72m 3 / h.

[0059] Set the air distribution volume in the coil area to 37000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com