On-line sampling system for metallurgical raw materials

A sampling system and raw material technology, applied in the field of metallurgy, can solve the problems of different particle sizes, occupying a large area of space, low efficiency, etc., and achieve the effect of reducing operators and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

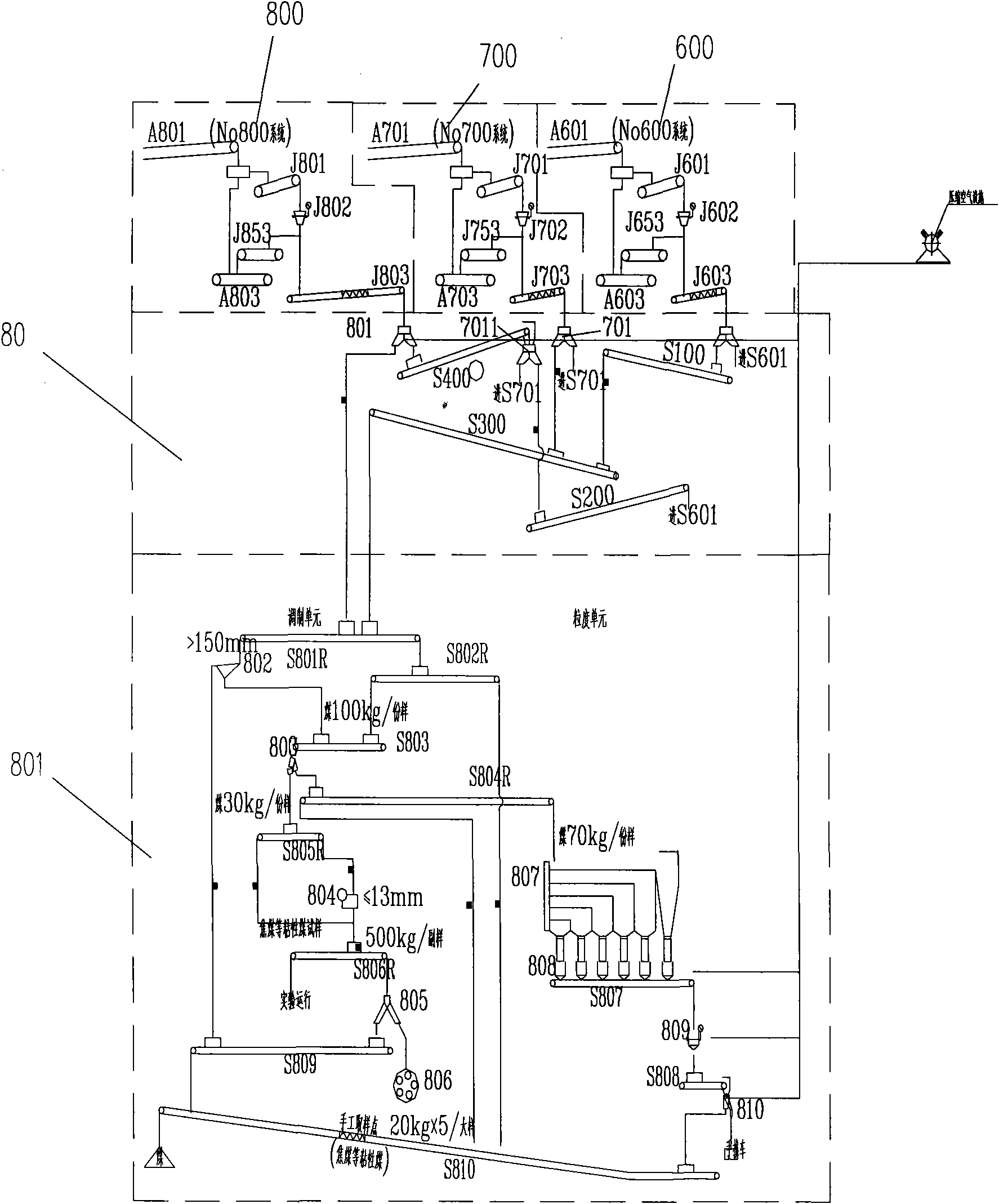

[0029] Such as figure 1 Shown: in the figure,

[0030] The ones with S in front of the number are belt conveyors;

[0031] 801, 701, 7011 are swing chute, 802 is auxiliary screen, 803 is primary shrinking machine, 804 is crusher; 805 is secondary shrinking machine 8, 806 is collector, 807 is raw coal online screening device; 808 is hopper , 809 is the hopper scale, 810 is the three-stage shrinking machine;

[0032] S801R, S802R, S803, S804R, S805R, S806R, S807, S808, S809, and S810 are belt conveyors for raw coal modulation units;

[0033] S100, S200, S300 and S400 in the intercommunication unit are belt conveyors.

[0034] A metallurgical raw material transportation and sampling system, which includes ore sampling units 600, 700, ore modulation units S601 and S701, coal sampling unit 800, and coal modulation unit 801, while the coal modulation unit includes several shrinking machines, and the transportation sampling system also includes An intercommunication unit 80, each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com