Continuous mercerized cotton yarn dyeing process

A mercerizing and process technology, applied in the field of yarn dyeing, can solve the problems of discontinuous production, unsatisfactory yarn gloss and softness, and high production cost, and achieve the effects of reduced production cost, good gloss and improved strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

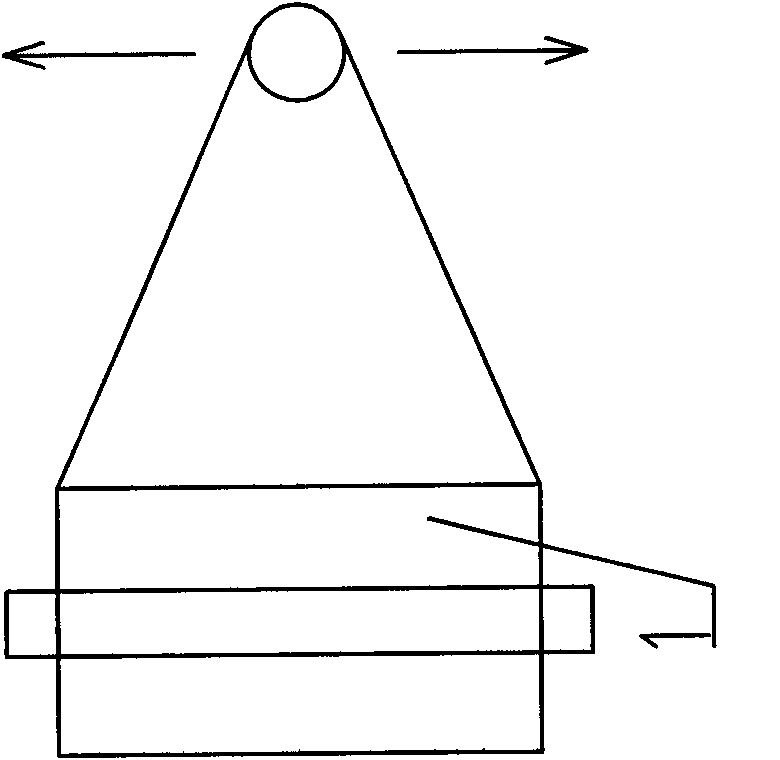

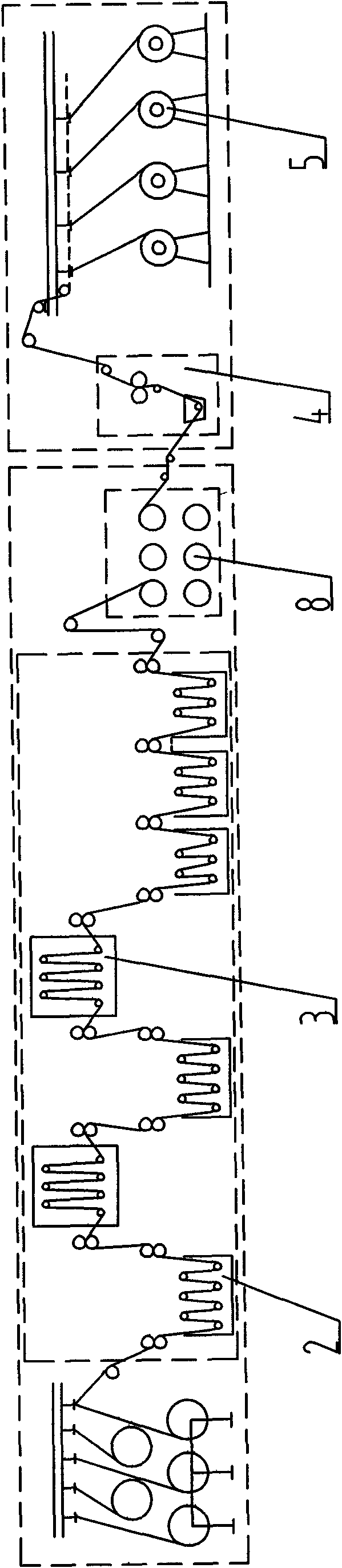

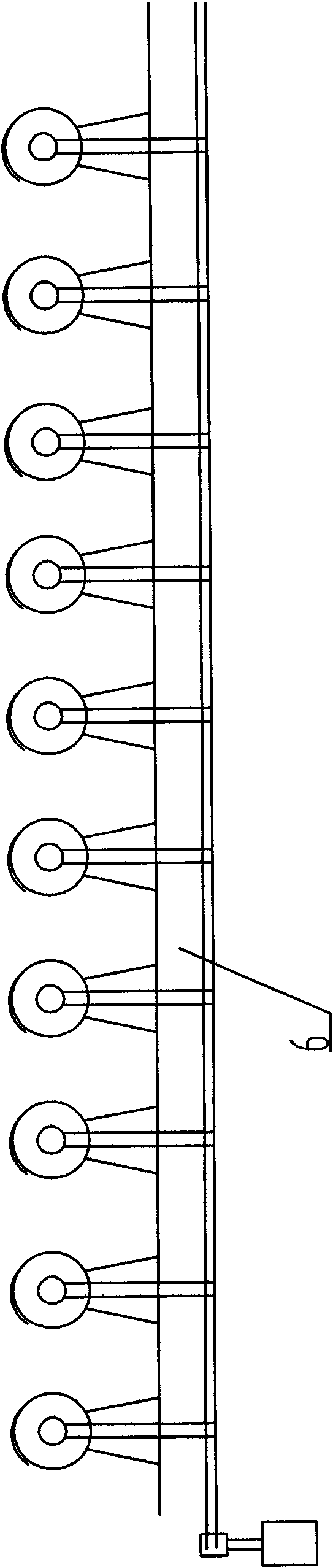

[0018] like figure 1 , 2 , shown in 3, 4, a kind of continuous mercerizing dyeing process, has following process steps successively: ball warping becomes a ball: with the ball warping machine 1 under the same tension force, the bundled yarn is reciprocally spirally wound on the warp beam; continuous mercerizing : Immerse the bundled yarn delivered in two padding machines 2 with the same concentration of alkali solution successively for twice padding, then carry out three 70°C hot water washings, and then dry them; padding dyeing: The bundled yarn after the mercerizing treatment is dyed with dyes and auxiliary agents at 25°C by the uniform padding car 4, and then wound up by the winding device 5; Cold stacking is carried out on the stacking device 6 to make it react to fix the color; soaping and drying: the bundled yarn after cold stacking is sequentially soaped and dried by the soaping machine 7 and the drying device 8 .

[0019] In the continuous mercerizing process, the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com