Integrate-assembled transformable backbone joint for spatial structure

A space structure, integrated technology, applied in the direction of building structure, building type, building, etc., can solve the problems of the joint components not being convertible, high complexity, and not having random assembly orientation, etc., to achieve convenient and easy construction. , the effect of good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

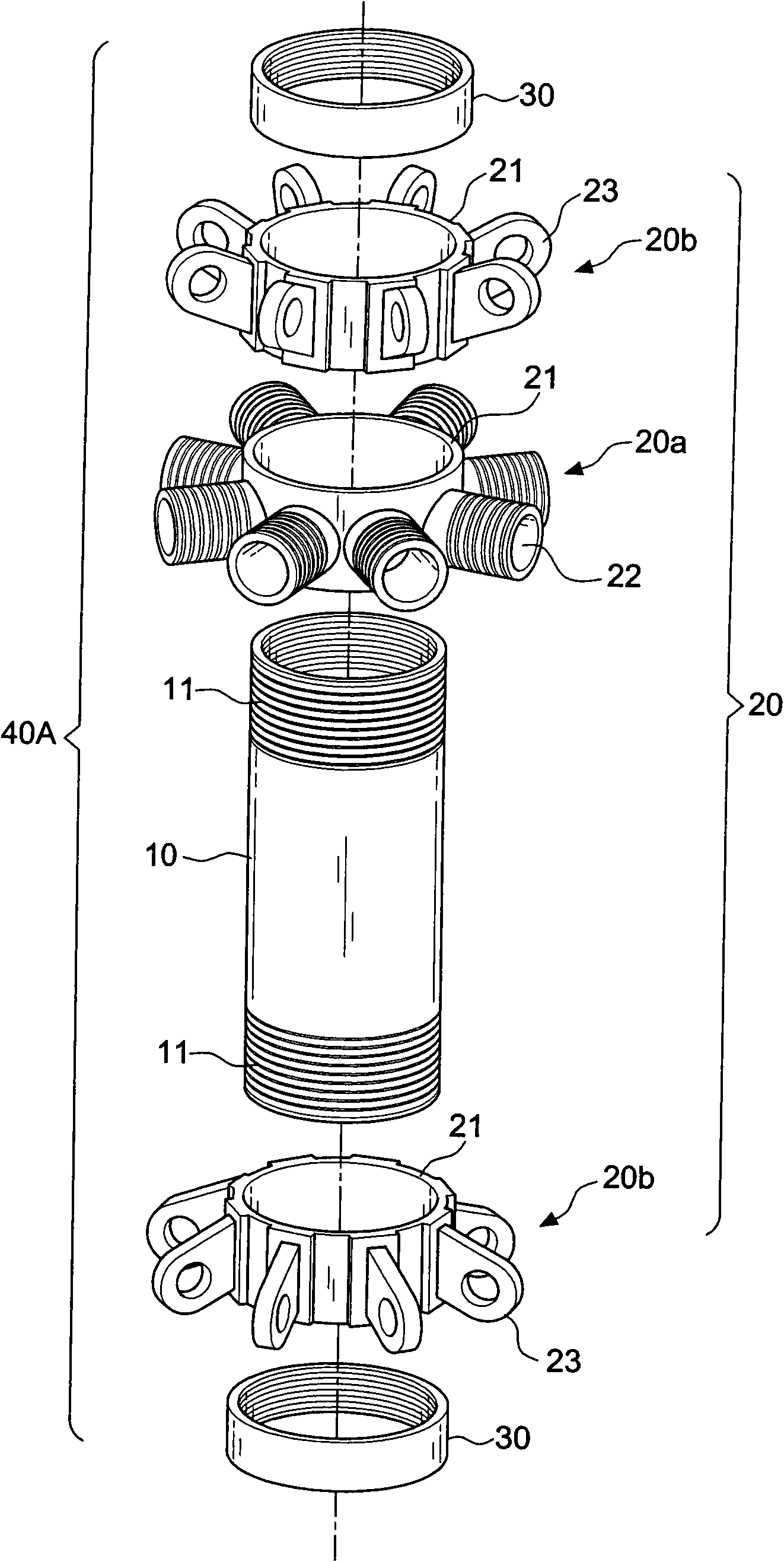

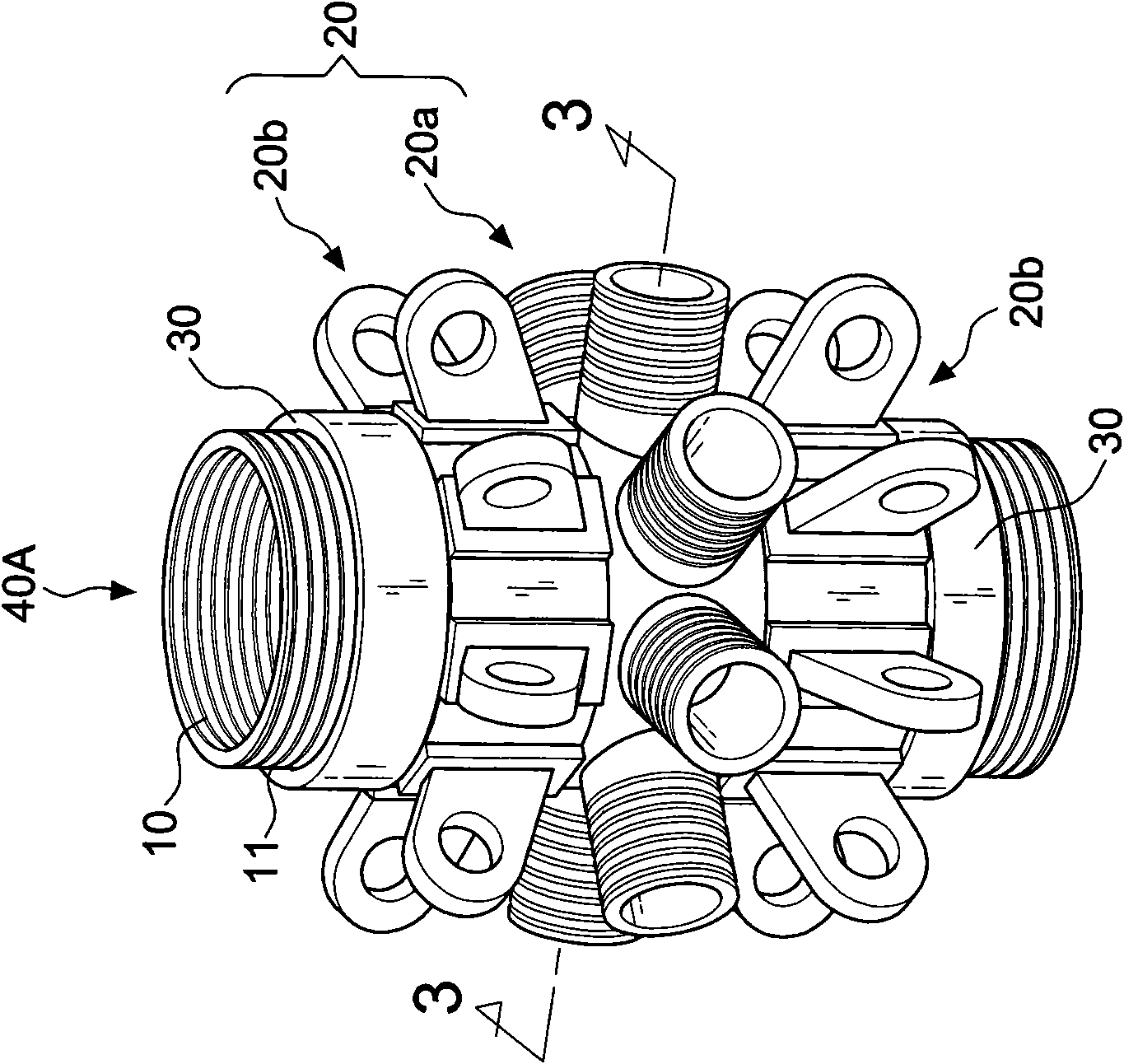

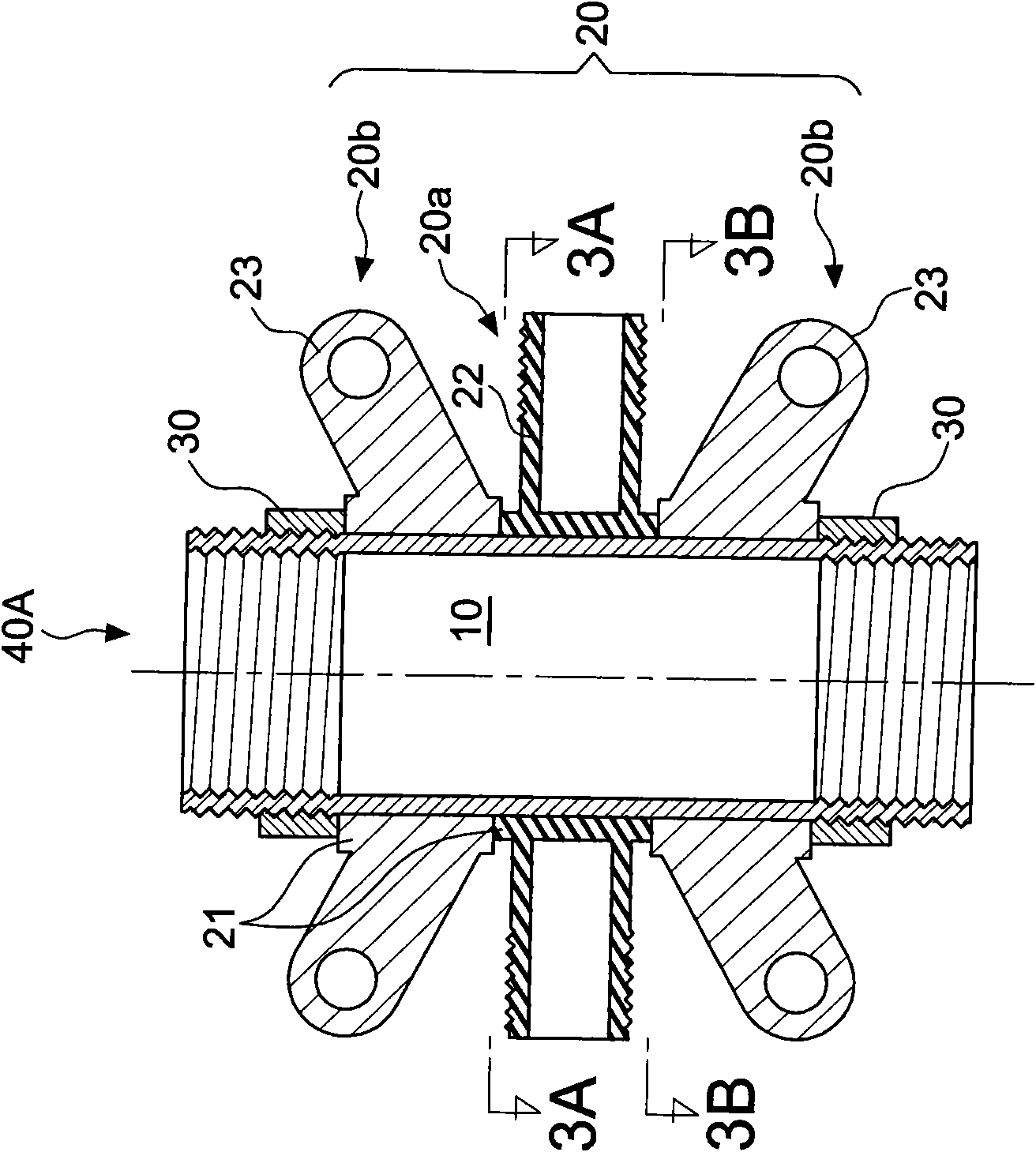

[0041] refer to figure 1 , figure 2 , image 3 , Figure 3A , Figure 3B , Figure 4A , Figure 4B As shown, the first preferred embodiment of the present invention includes: a backbone 10, which is an axial rod member of a predetermined form, which is the core (main body) of the entire joint 40A, and the axial joints 11 at the upper end and the lower end of it can be arranged into threaded bodies, but not limited thereto.

[0042] The multi-layer convex extension seat 20 is equipped with a body for setting on the outer peripheral surface of the backbone 10. In this embodiment, it includes a middle layer convex extension seat 20a and two upper and lower layer convex extension seats 20b, The seat body of the convex extension seat 20 of each layer is set in the form of a ring body 21, that is, in this embodiment, the ring body 21 is the seat body of the convex extension seat 20, which is sheathed in a sheathing manner On the outer peripheral surface of the backbone 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com