Control method and operation method for optimizing beaten sound of parallel propeller fan systems

A technology of axial flow fan and control method, which is applied in pump control, mechanical equipment, machine/engine, etc., and can solve problems affecting product sound quality, comfort, and consistent speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

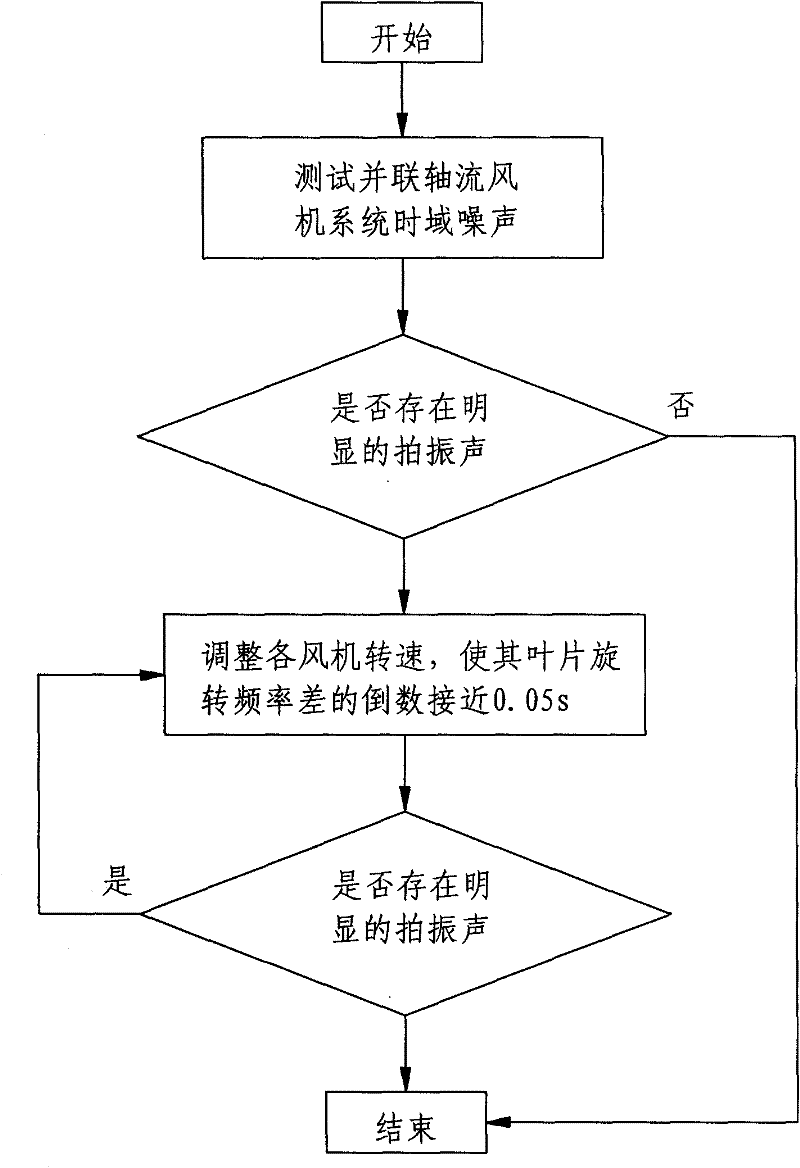

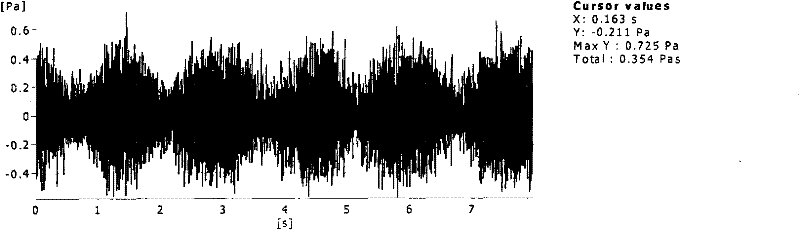

[0039] see figure 1 , for a newly developed parallel axial fan system, especially a large-diameter, high-speed parallel axial fan system, it is first necessary to test the time-domain noise characteristics of the parallel axial fan system, through time-domain spectrum or simple subjective Evaluate the system for low frequency flapping noises. If you can hear obvious low-frequency periodic noise, or its time-domain spectral characteristics are similar to figure 2 , it shows that there is beating vibration in the parallel axial flow fan system, and it is necessary to adjust the PWM of each motor. The beating vibration period caused by the rotational noise of any two fan blades in 1 / (f 2 -f 1 ) is close to the minimum time resolution of the human ear, 0.05s.

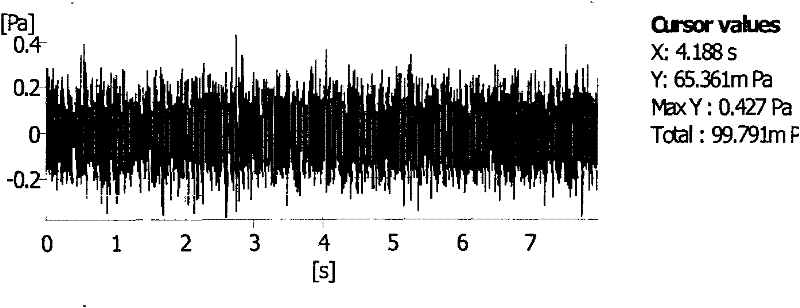

[0040] After adjustment, perform the noise test. If you can still feel the beating vibratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com