Control method for controlling burning and corresponding automatic chip burning equipment

A technology of burning equipment and control method, applied in the field of chip burning equipment and semiconductor process equipment, can solve the problem that the burning equipment cannot be controlled to support online burning and non-online burning, there is no burning equipment, and the process operation is not Flexibility and other issues to achieve the effect of high output, low cost, and simplified inventory management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

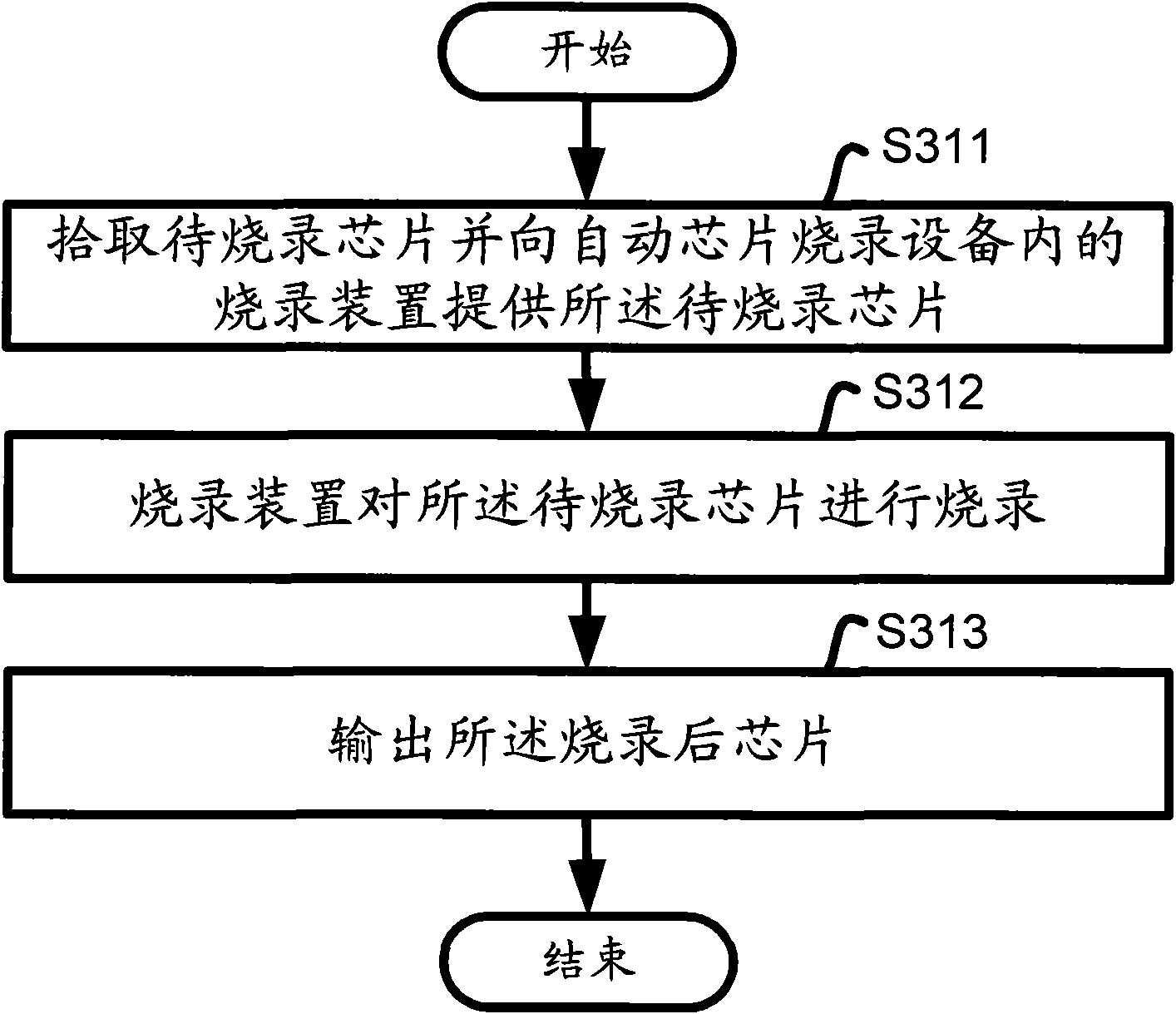

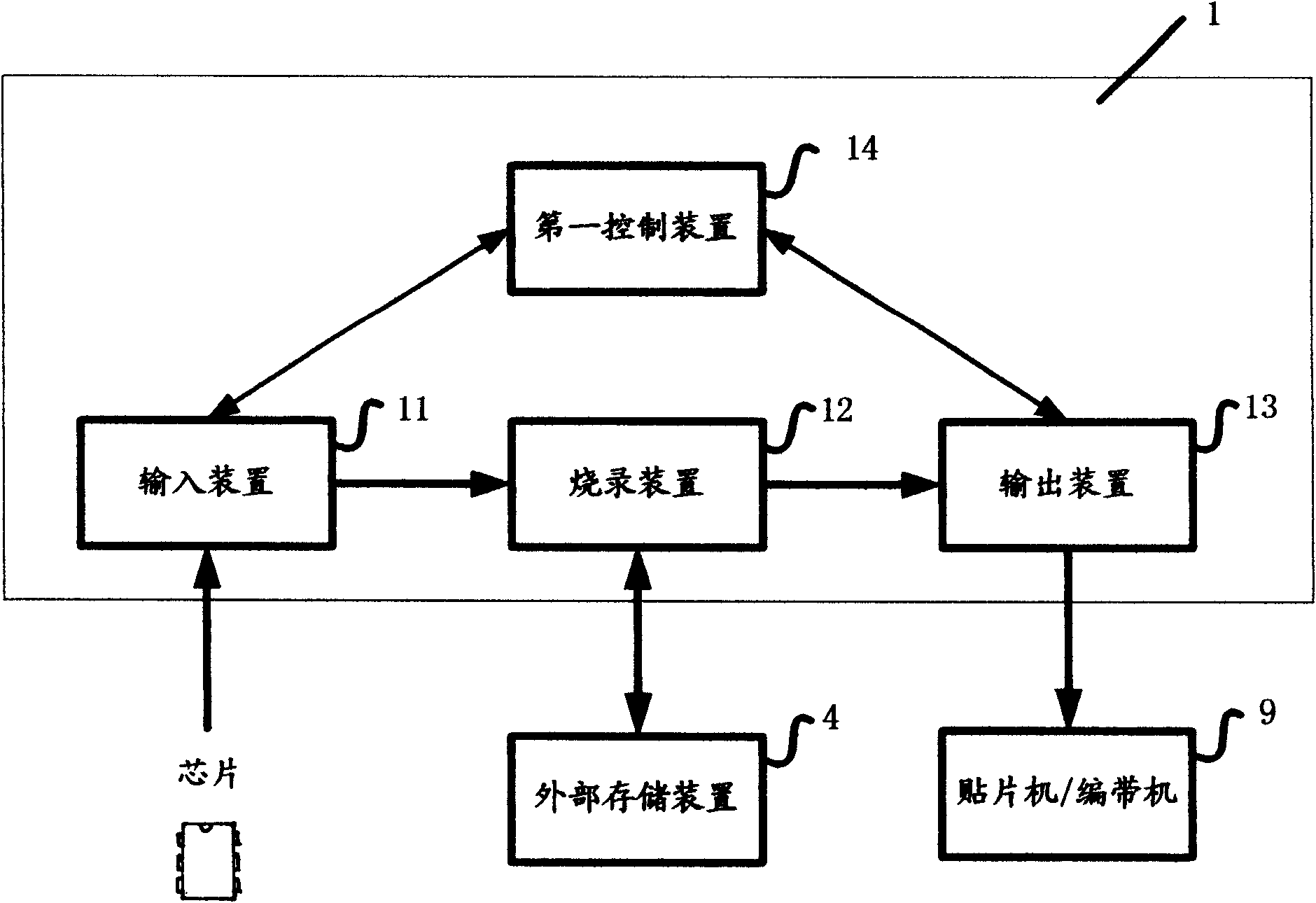

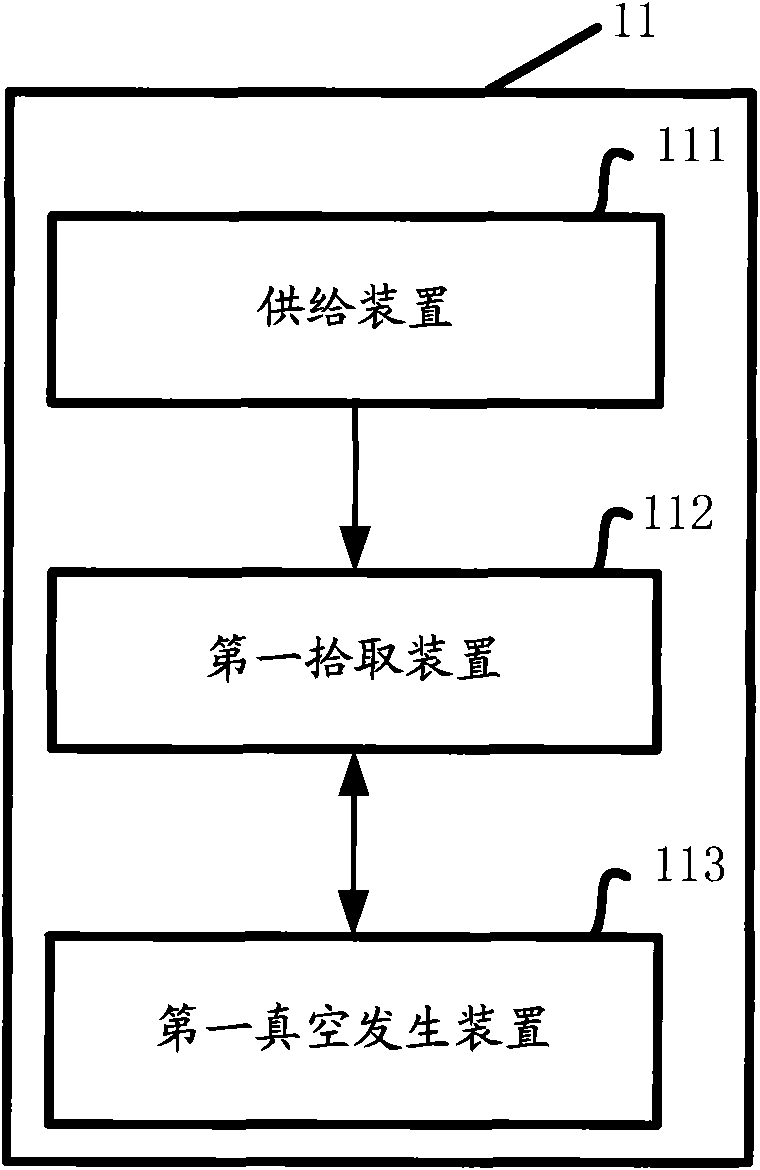

[0027] Preferably, on the basis of the existing chip burning equipment, the present invention enables the burned chip to be supplied to the placement machine or to the tape machine, thereby realizing online burning on one burning equipment. The control process of integrating recording and non-online programming. specifically, figure 1 According to the first embodiment of the present invention, a flow chart of a method for controlling chip transmission after automatic chip programming equipment is controlled by the present invention is shown. First, step S311 is executed to pick up the chip to be burned and provide the chip to be burned to the burning device in the automatic chip burning equipment. Those skilled in the art understand that this step can be achieved through the automatic chip burning equipment provided by the present invention. The pick-up device in is completed, and such pick-up device can be realized with reference to the prior art. Then, enter step S312, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com