Magnetic core finishing machine

A sorting machine and magnetic core technology, which is applied in the direction of inductance/transformer/magnet manufacturing, electrical components, circuits, etc., to achieve the effect of saving work space, reducing production personnel, and reducing labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

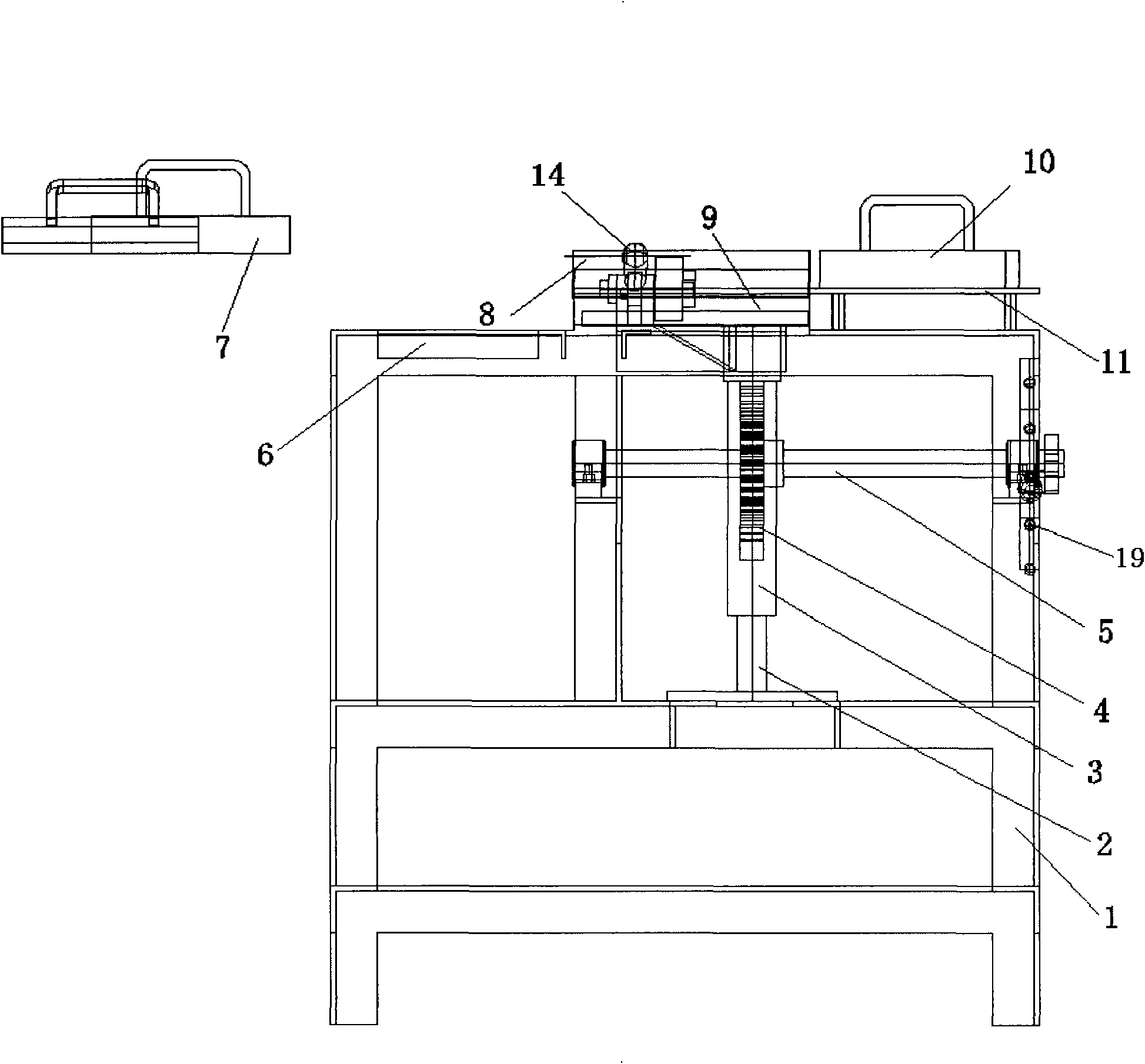

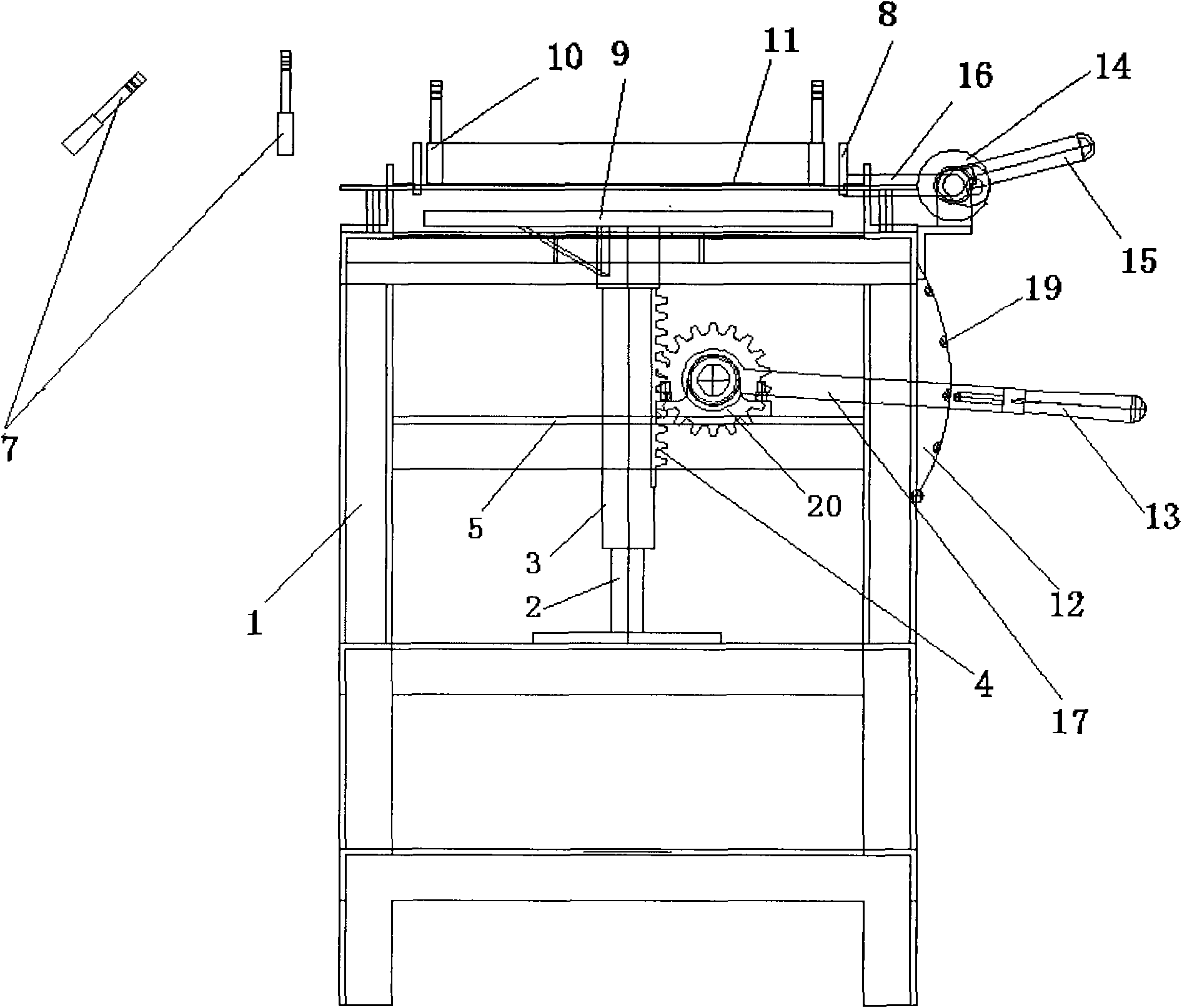

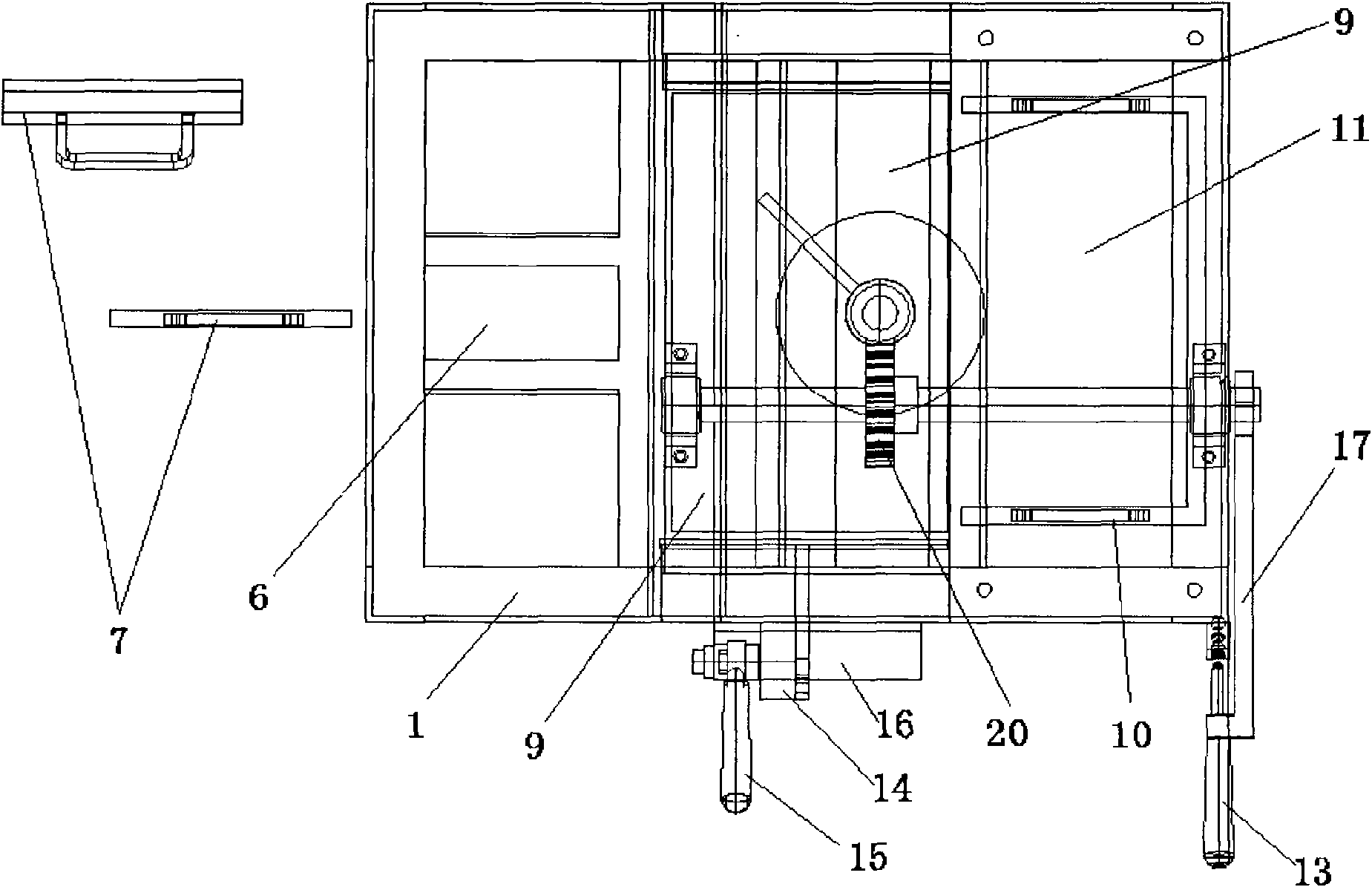

[0012] Such as Figures 1 to 3 As shown, the main body of the present embodiment is a frame 1, and the upper surface of the frame 1 is provided with a feeding platform 6, a layered lifting platform 9, a layered shaping platform 11 and a push plate eccentric wheel 14, the feeding platform 6, the layered lifting platform The positions of the platform 9 and the layered shaping platform 11 are arranged from left to right. A mechanical push plate 8 is arranged on the layered lifting platform 9. One side of the mechanical push plate 8 is provided with a push plate eccentric wheel 14, and the push plate eccentric wheel 14 is fixed on the frame 1, and the push pedal eccentric wheel 14 is provided with a push pedal transmission rod 16 and a mechanical push pedal handle 15, and the push pedal transmission rod 16 is matched with the mechanical push pedal 8. A layered shaping frame 10 is arranged on the layered shaping platform 11 .

[0013] The frame 1 below the layered lifting platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com