Wafer supporting device and etching device

A wafer carrying and wafer technology, which is applied in the manufacture of discharge tubes, electrical components, semiconductor/solid-state devices, etc., can solve the problems of damage to the focus ring 122, deterioration of etching uniformity, and impact on focusing performance, etc., to increase the use of The effect of life, improving yield and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

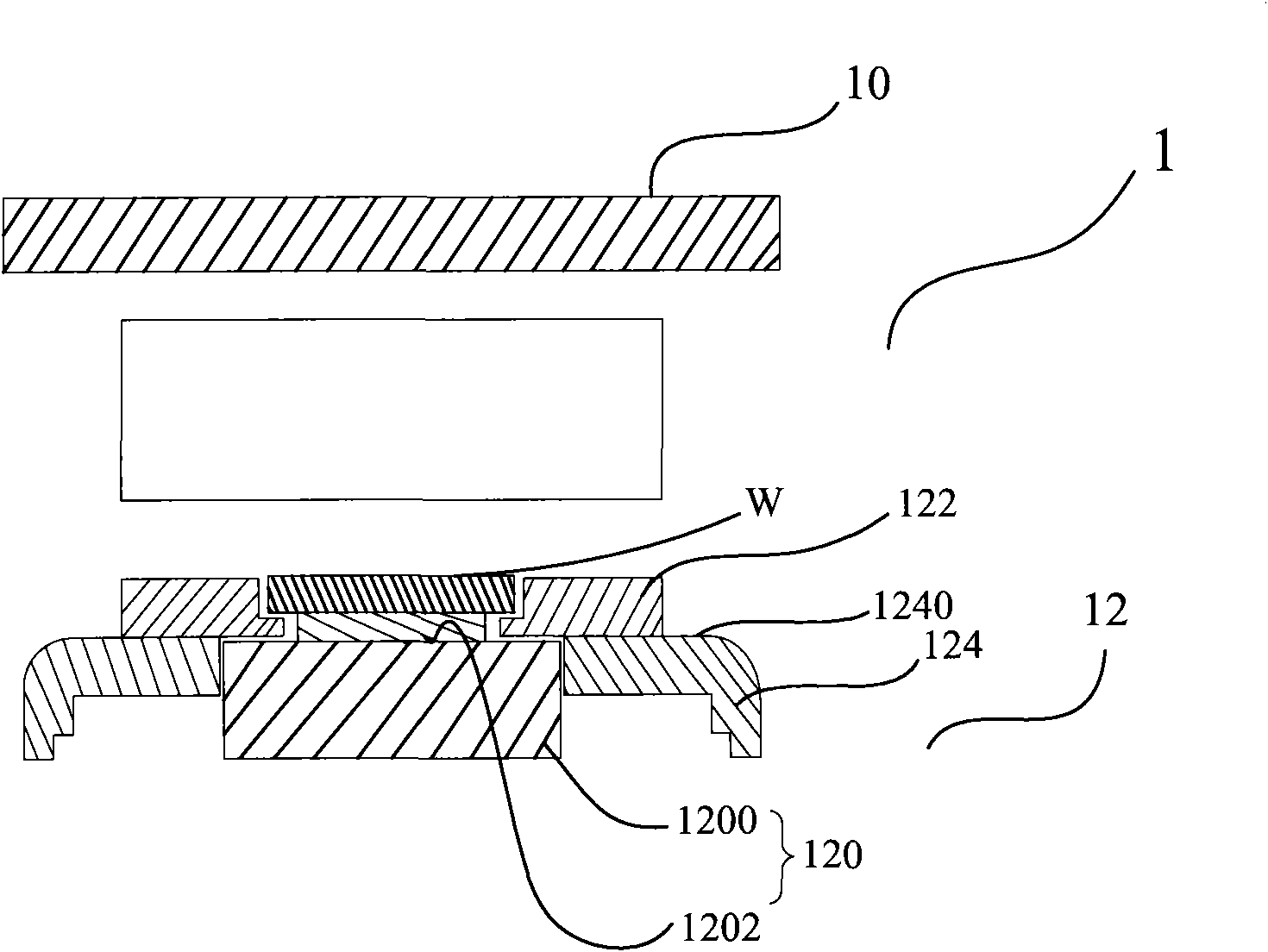

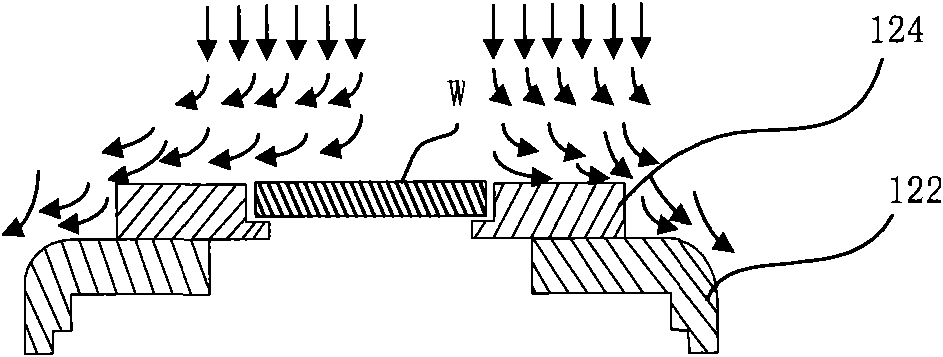

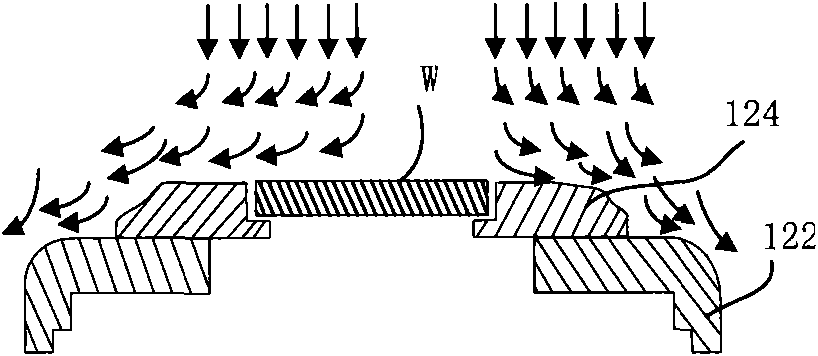

[0022] The present invention provides a wafer carrier device applied to a semiconductor manufacturing process, comprising an electrostatic chuck, a focus ring and an insulating member, wherein the surface of the insulating member has a first section and a second protrusion protruding from the first section. section. Embodiments of the present invention will be described below by taking an etching apparatus for wafer etching processing as an example with reference to the accompanying drawings.

[0023] image 3 It is a longitudinal cross-sectional side view of an embodiment of the etching apparatus of the present invention. like image 3 As shown, the etching apparatus 3 may include a hermetic processing vessel (not shown) that is grounded. The airtight processing container includes an upper electrode 30 and a wafer carrier 32 disposed opposite to the upper electrode 30 . Among them, the upper electrode 30 is an etching gas (for example, including C 4 F 8 gas, C 5 F 8 G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com