Molybdenum phosphide (MoP) prepared by hypophosphite precursor thermal decomposition method

A technology of hypophosphite and molybdenum phosphide, which is applied in the direction of phosphide, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problems of difficult realization of programmed temperature reduction and high preparation temperature, and achieve low equipment cost and low price Effect of cheap, good HDS and HDN activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

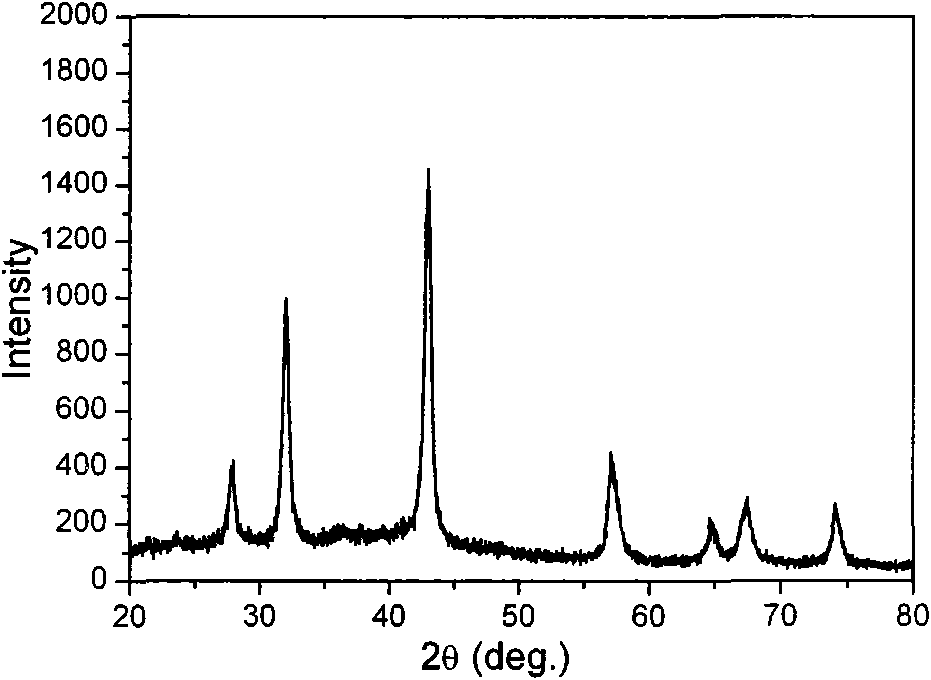

[0015] First, 7.33g of Na 2 MoO 4 .2H 2 O and 12.85 g NaH 2 PO 2 .H 2 O was added to 100ml deionized water respectively, and after dissolving for 10 minutes, the resulting solution was put into a petri dish and dried at 60°C. Then put the dried white precursor powder into the reactor, heat treatment at 300°C for 10min under the protection of static nitrogen, and then wash the obtained product with water and then dry it. The obtained sample is named A, and A has attached figure 1 Characteristics.

Embodiment 2

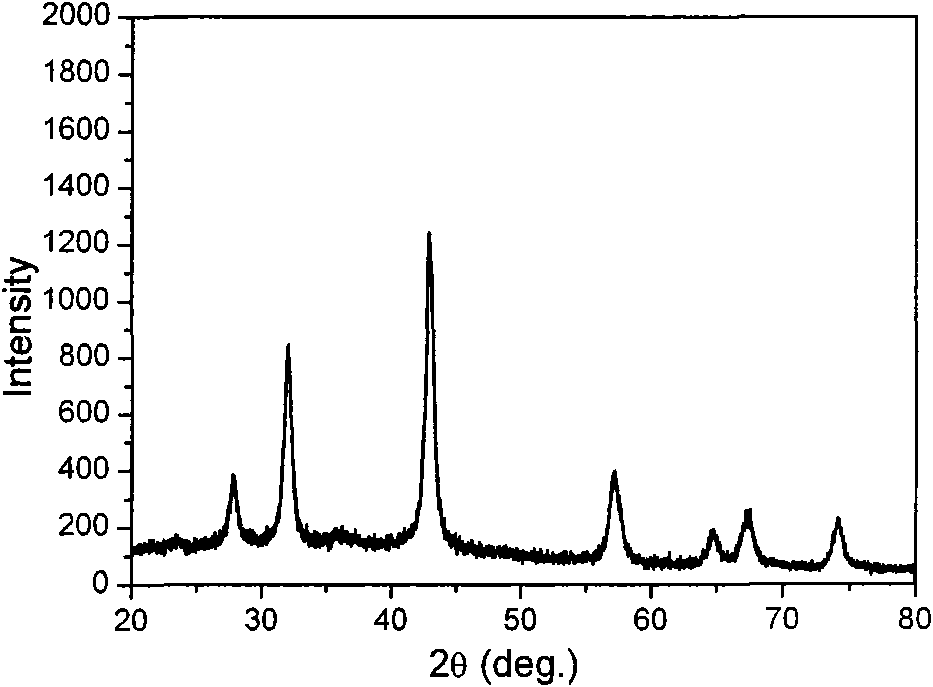

[0017] The preparation process is the same as that of sample A, only changing the NaH 2 PO 2 .H 2 The amount of O is 16.06g, and other conditions remain unchanged. The resulting sample is named B, and B has attached figure 2 Characteristics.

Embodiment 3

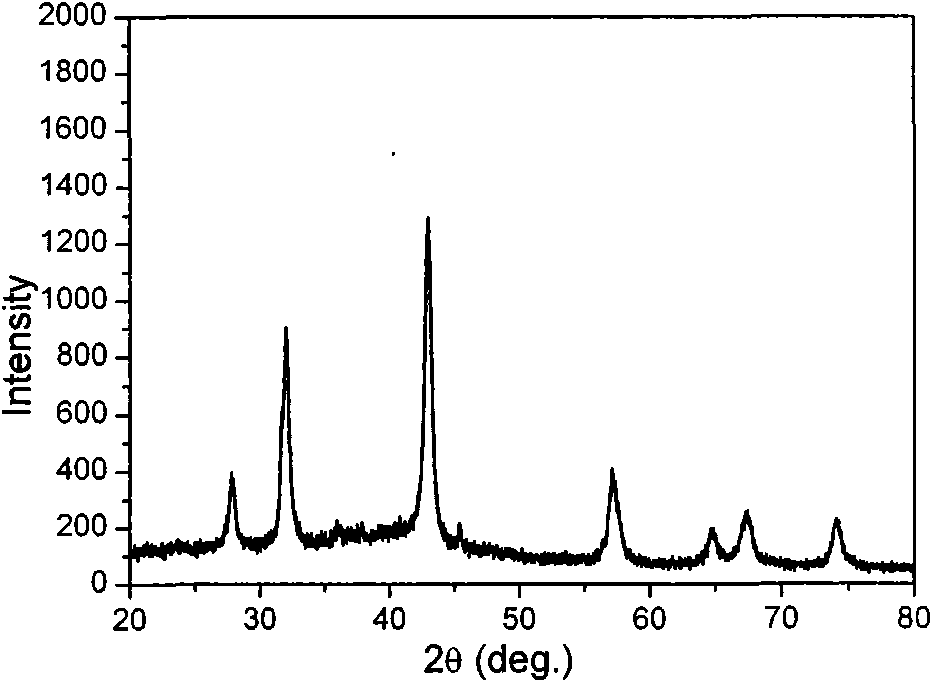

[0019] The preparation process is the same as that of sample A, only the heat treatment temperature is changed to 500°C, and other conditions remain unchanged. The obtained sample was named C, and C has attached image 3 Characteristics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com