Apparatus for feeding and aligning sheets fed to a processing machine, in particular a printing machine

A technology for processing machines and sheets, which is applied in the field of devices for feeding sheets by sheet processing machines, and can solve problems such as distortion of items to be conveyed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

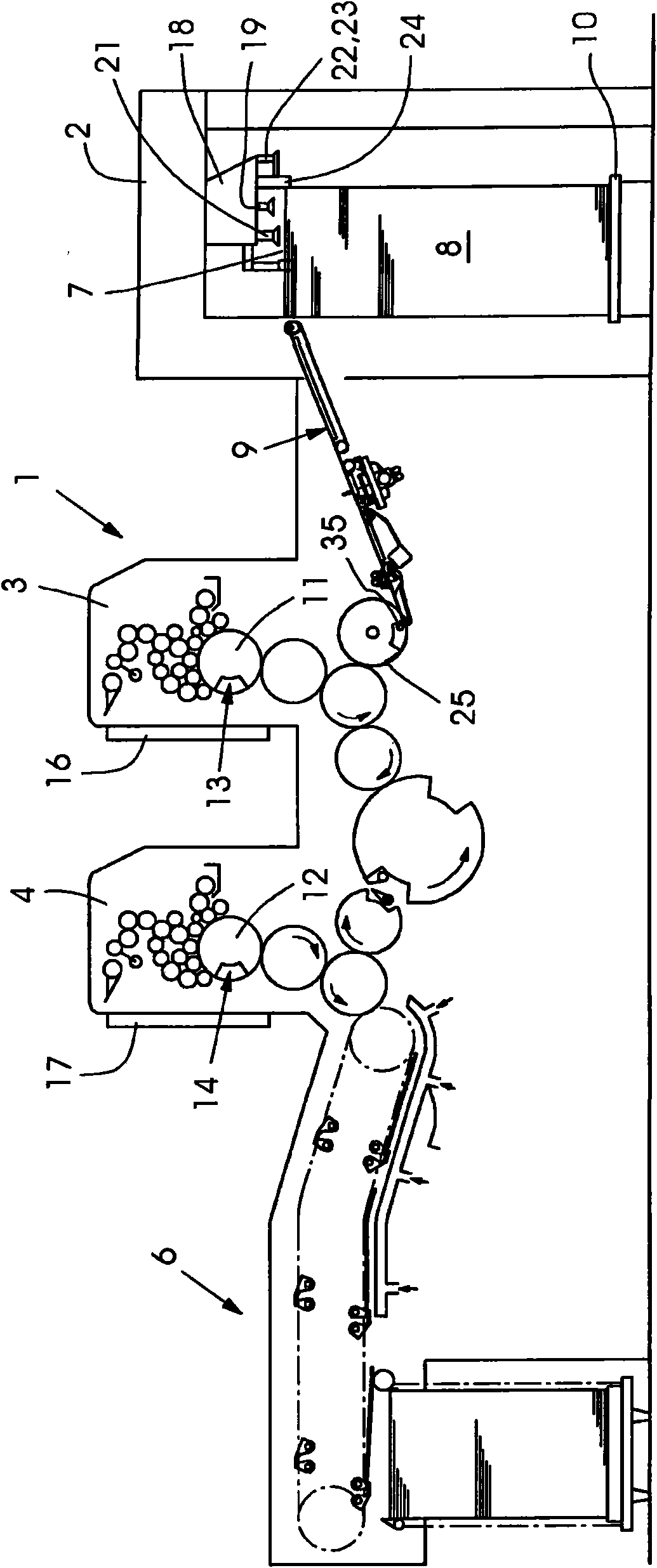

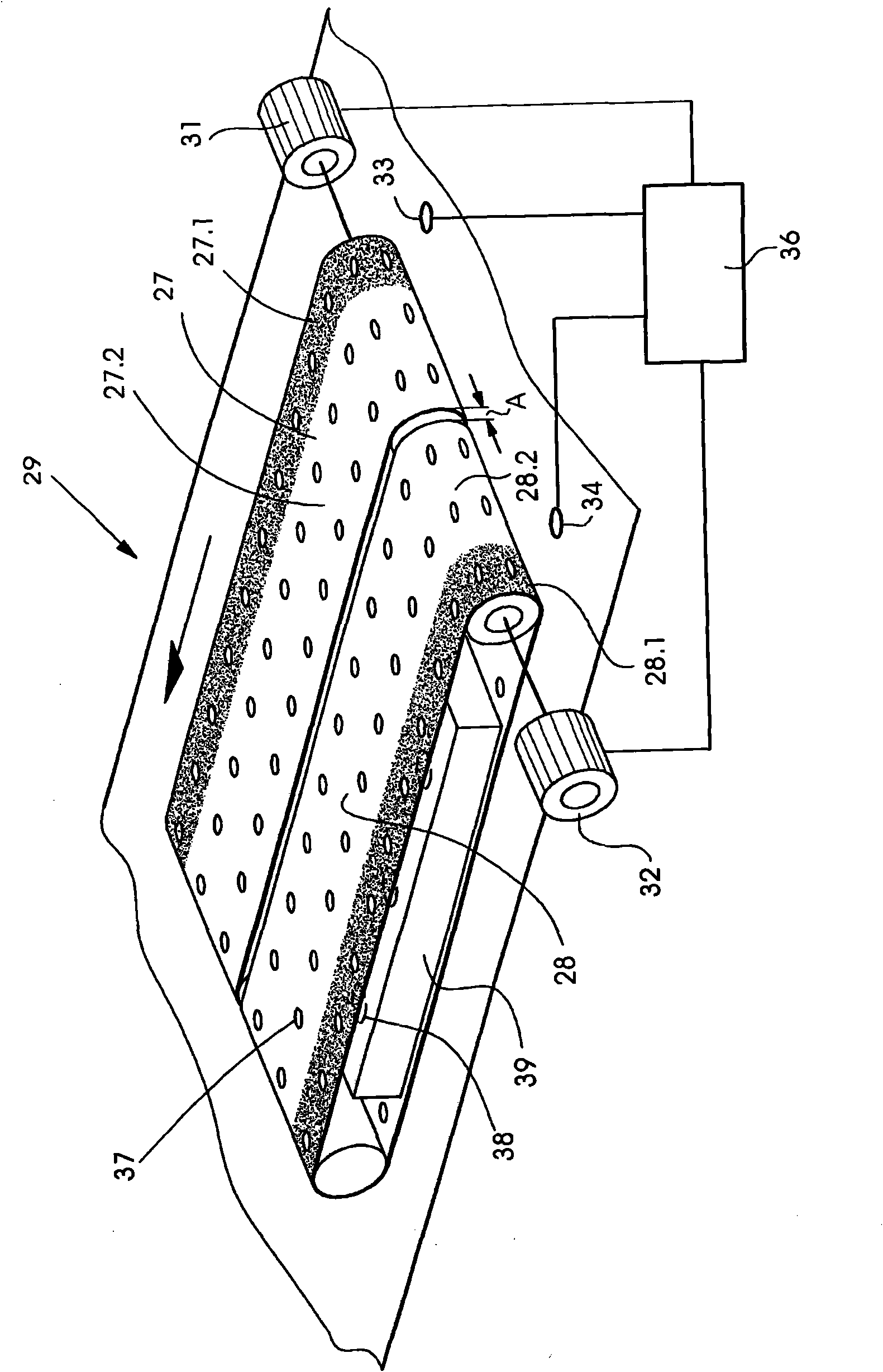

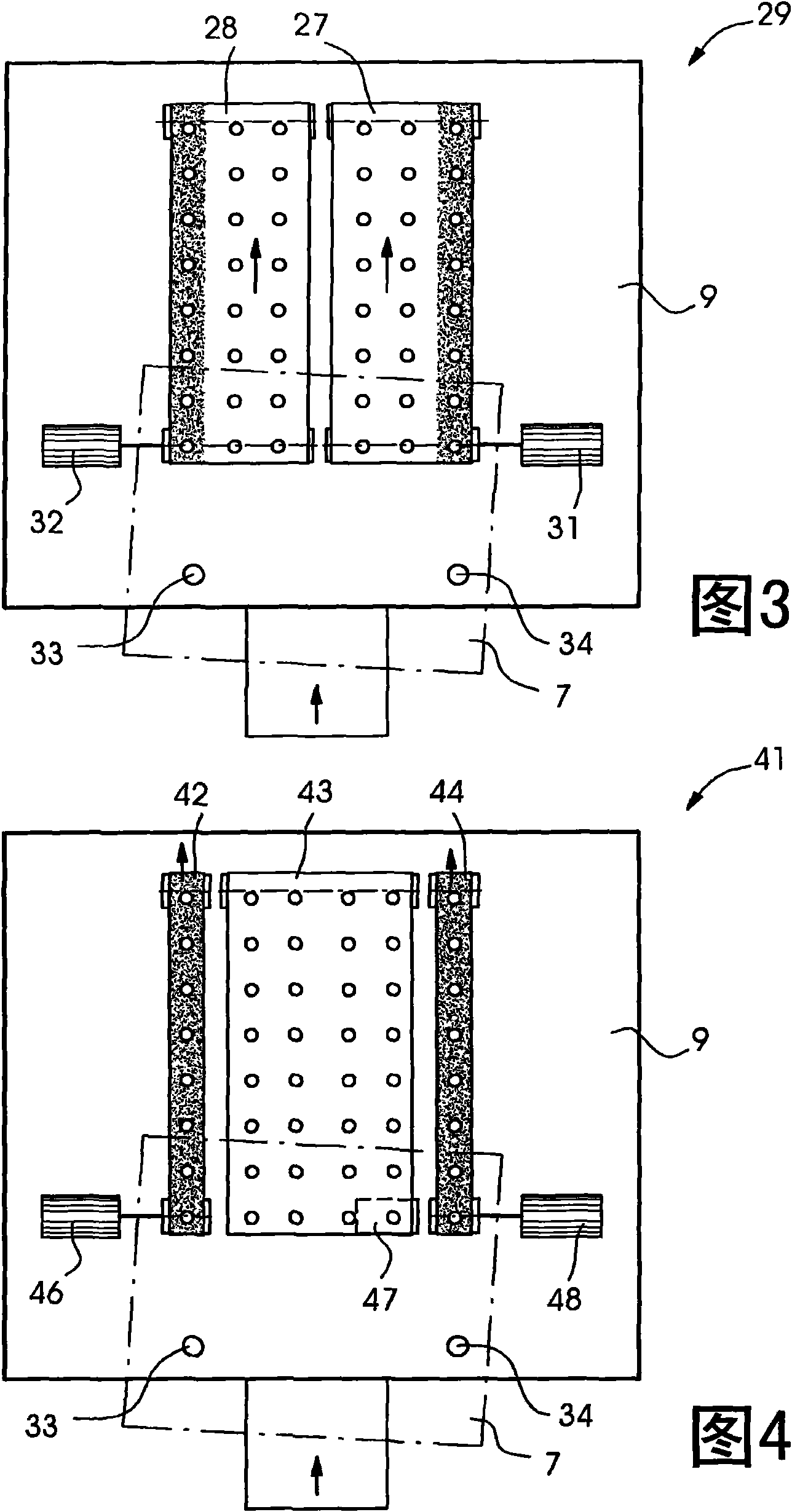

[0025] A machine for processing sheets 7 , for example a printing press 1 , has a feeder 2 , at least one printing unit 3 or 4 and a delivery 6 . The sheets 7 are removed from the sheet stack 8 and fed to the printing units 3 and 4 in sheets or in sheets via an infeed station 9 . In a known manner, these printing units each comprise a printing form cylinder 11 , 12 and blanket cylinders 15 , 20 each interacting with said printing form cylinder. The printing plate cylinders 11 and 12 each have a clamping device 13 , 14 for holding the flexographic printing plate. Furthermore, a device 16 , 17 for semi-automatic or fully automatic plate changing is assigned to each plate cylinder 11 , 12 .

[0026] The sheet stack 8 lies flat on a stacking plate 10 which can be raised and lowered in a controlled manner. The extraction of the sheets 7 takes place from the upper side of the sheet stack 8 by means of a so-called suction head 18, which essentially has a plurality of lifting and pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com