Automatic control mechanism of carbureter air choke valve of general gasoline motor

A general-purpose gasoline and choke technology, applied to carburetors, engine components, machines/engines, etc., can solve the problems of too thick mixed gas, automatic shutdown, thick mixed gas, etc., and achieve the effect of improving start-up performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

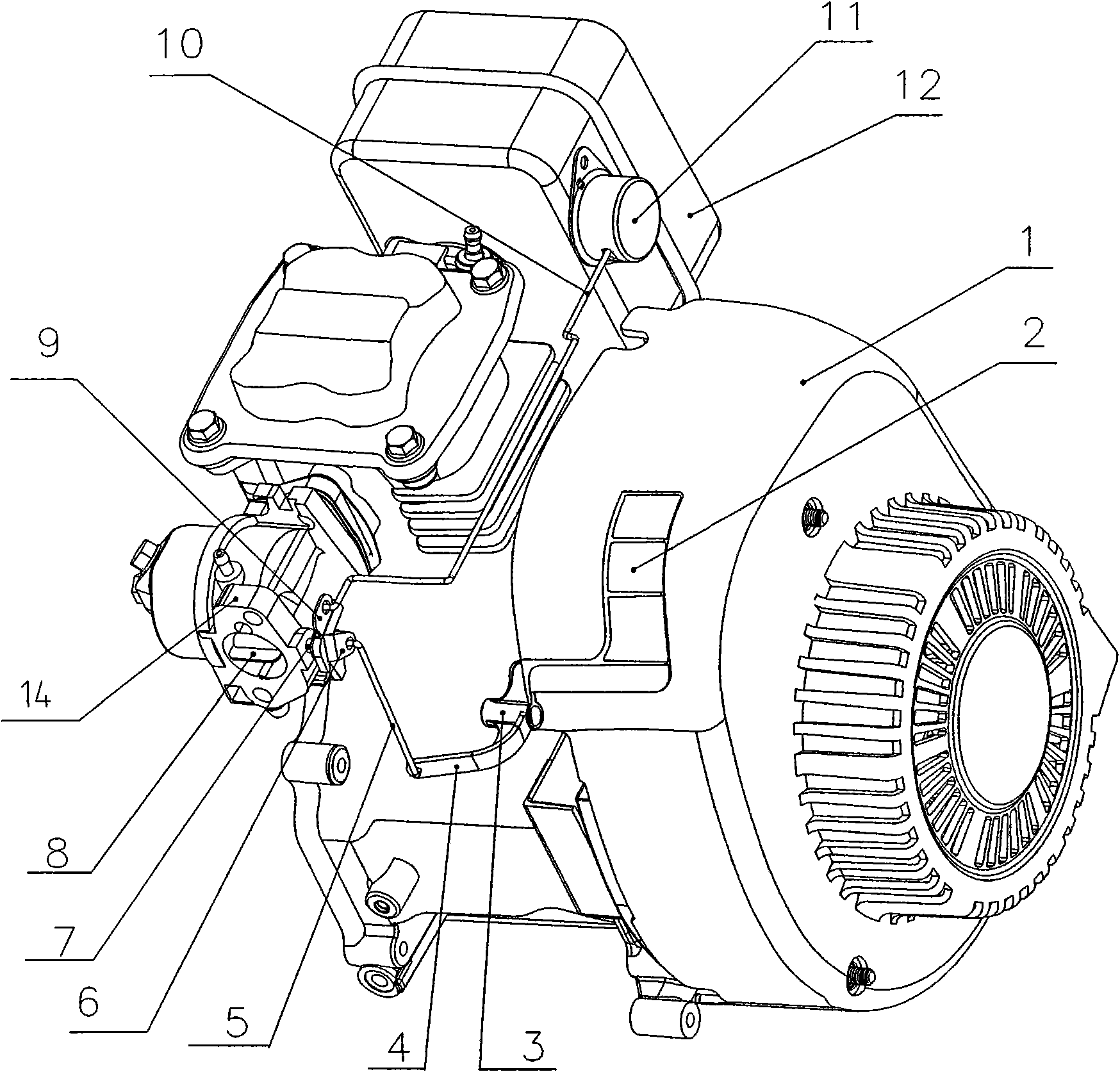

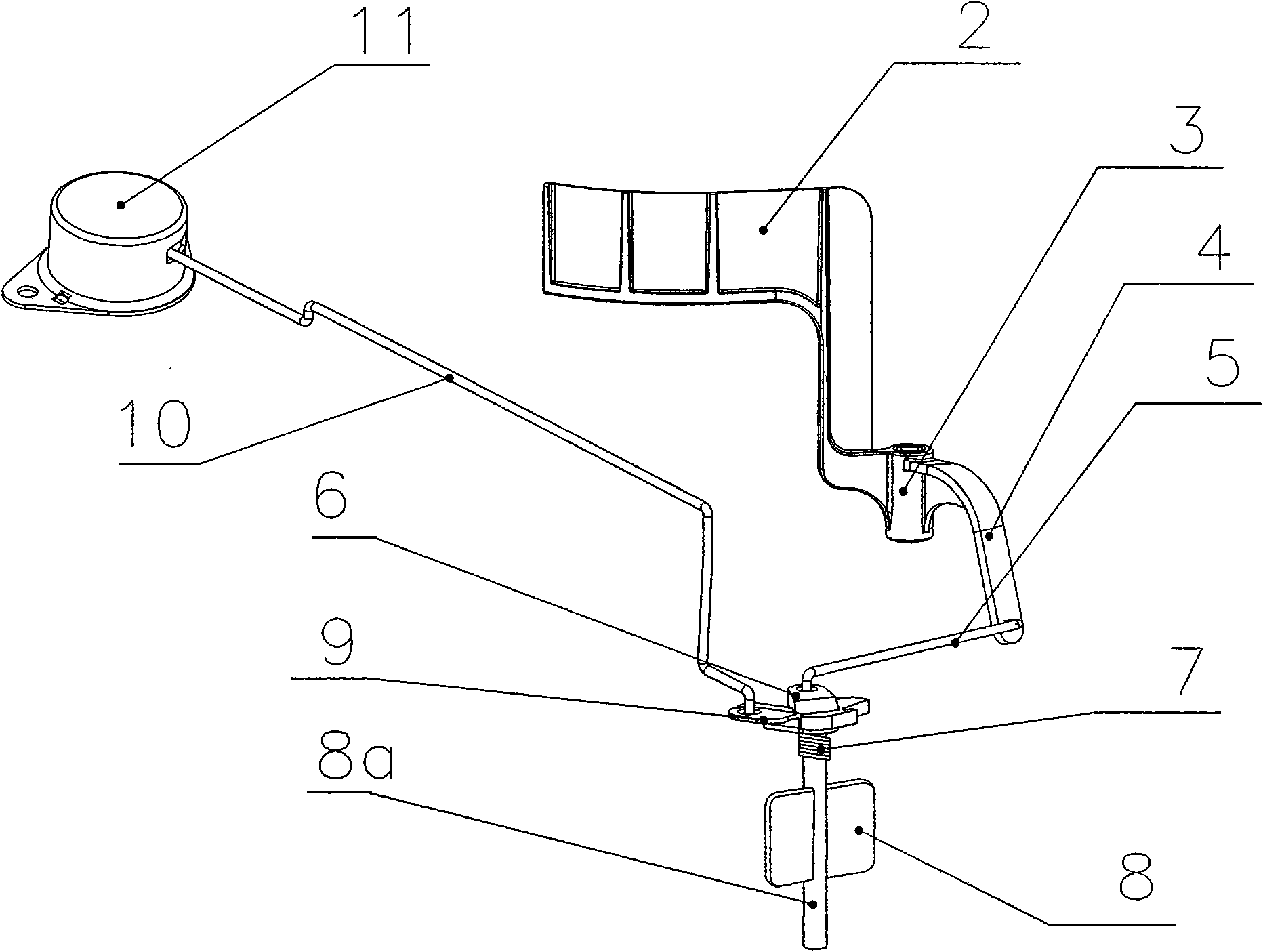

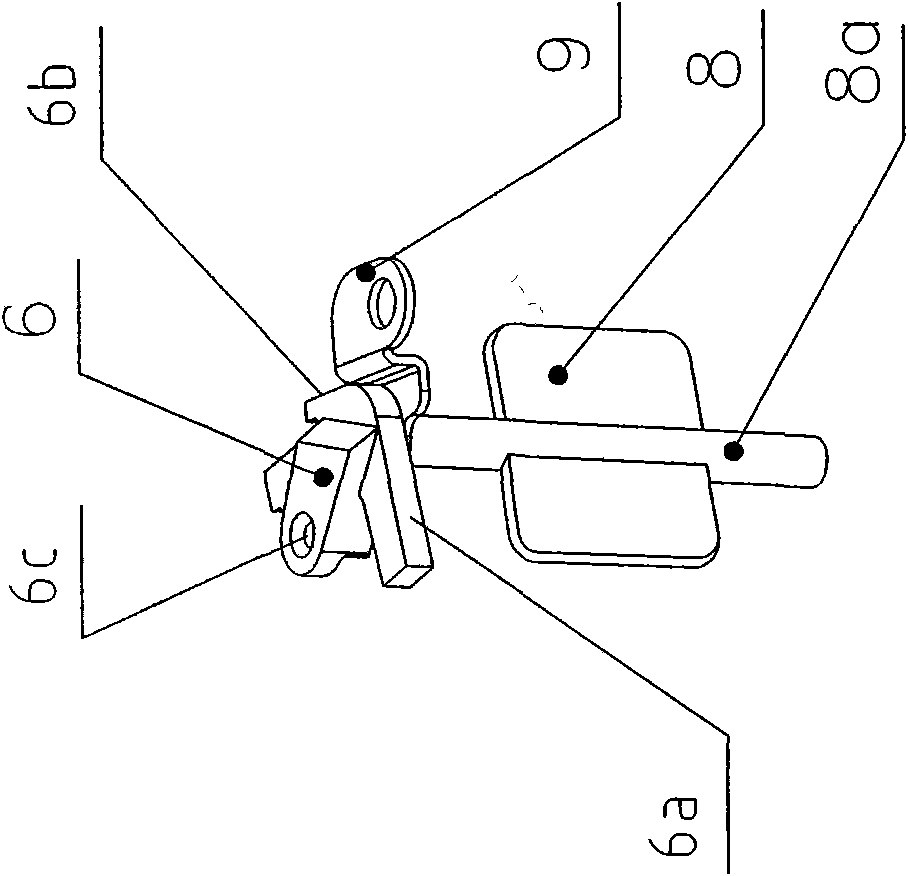

[0021] see Figure 1 to Figure 7, Carburetor 14, fan wind guide cover 1, muffler 12 are installed on general gasoline engine. A choke valve 8 is provided at the air inlet of the carburetor 14, and the choke valve 8 is rotatably installed in the air inlet of the carburetor 14 through a shaft 8a. A control device for driving the opening of the choke door is rotatably connected on the fan guide cover 1, one end of the control device for driving the opening of the choke door is a blade 2, and the other end is a control arm 4, and the blade 2 is connected to the control arm 4. Between the control arms 4 is a rotation center bushing 3, the blade 2, the control arm 4 and the rotation center bushing 3 of the control device for driving the choke to open are integrally formed, the blade 2 is a single blade, and the control arm 4 It is a curved shape, and the control arm 4 is provided with a pull rod jack, and the bushing 3 is gap-fitted on the shaft provided on the side wall of the fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com