Capacitance induction type liquid level sensor

A liquid level sensor and capacitive sensing technology, applied in the field of liquid level sensors, can solve the problems of inability to calculate the result value, circuit unreliability, detection errors, etc., to reduce the influence of detection range and accuracy, improve stability and reliability, The effect of wide detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The capacitive inductive liquid level sensor of the present invention will be further described below in conjunction with specific embodiments.

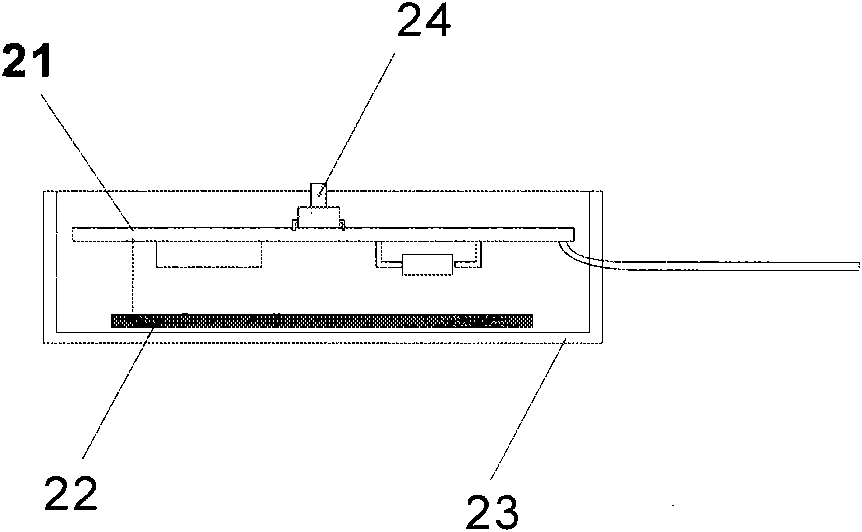

[0038] Such as figure 1 As shown, a capacitive sensing liquid level sensor includes a PCB circuit board 21, an induction board 22 and an outer box 23, wherein the PCB circuit board 21 is a printed circuit board with components to form a circuit, and the induction board 22 is copper foil, but In actual implementation, iron foil or other metal foils can also be used instead to achieve the same or similar functions, but not limited thereto; the outer box 23 is made of plastic, but in actual embodiments, other materials can also be used instead , to achieve the same or similar functions, not limited thereto; the PCB circuit board 21 and the induction board 22 are placed in the outer box 23, and the induction board 22 and the PCB circuit board 21 are electrically connected with the PCB circuit board 21 in structure. The boards 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com