Method for manufacturing composite conductive wire and heating monofilament of composite conductive wire

A technology of composite wires and manufacturing methods, applied in the direction of cable/conductor manufacturing, conductors, conductive materials, etc., can solve the problems of unfavorable overhead line high-altitude operations, wire influence, low assembly efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The details of the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. However, it should be noted that the following description is merely exemplary in nature, and is not intended to limit the disclosure, application, or use of the present invention.

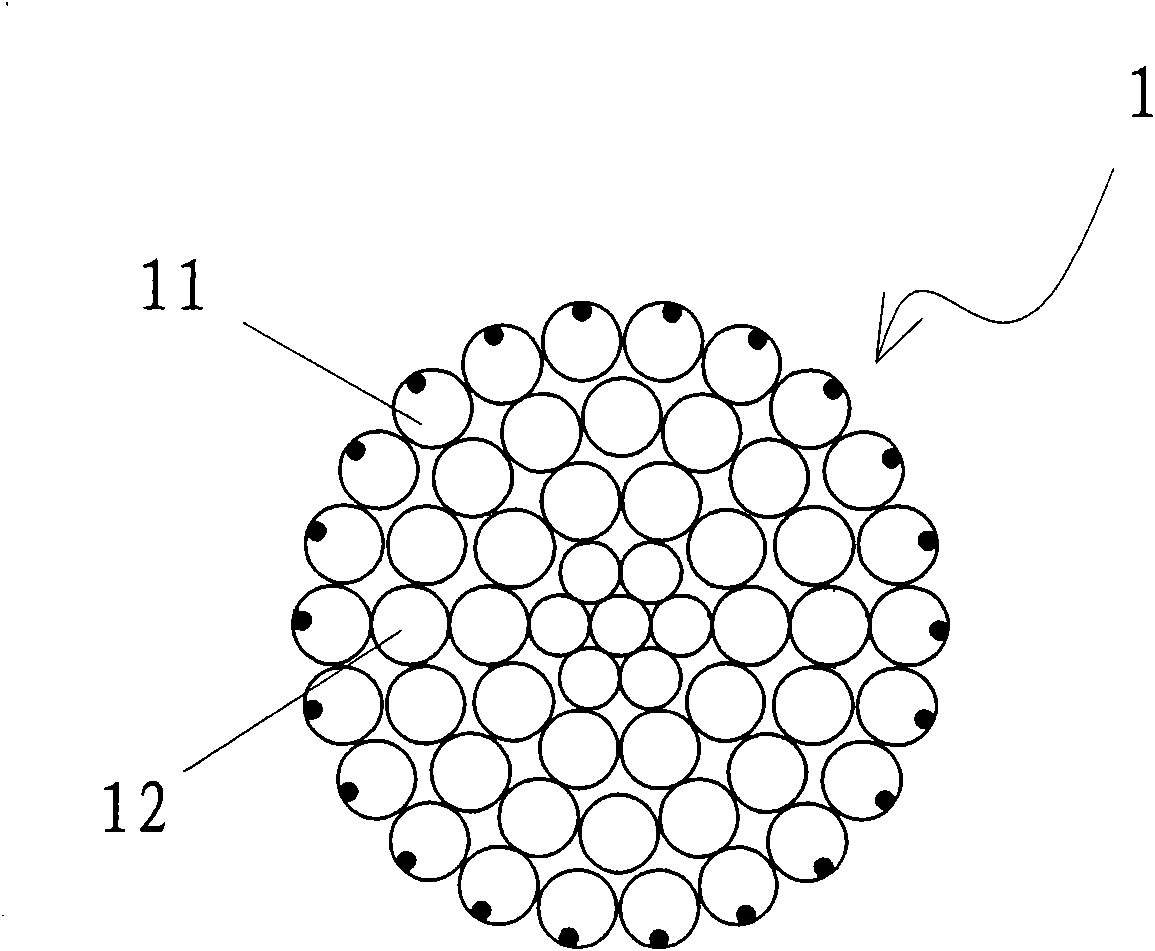

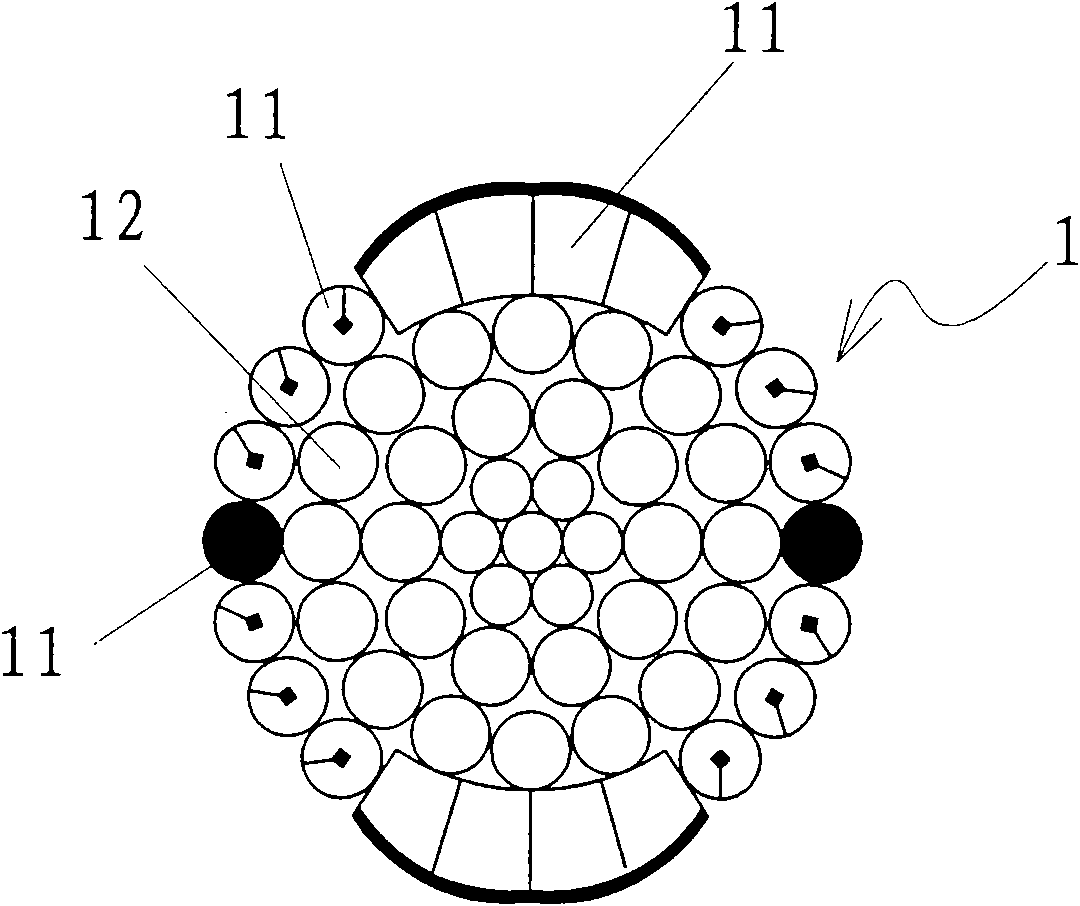

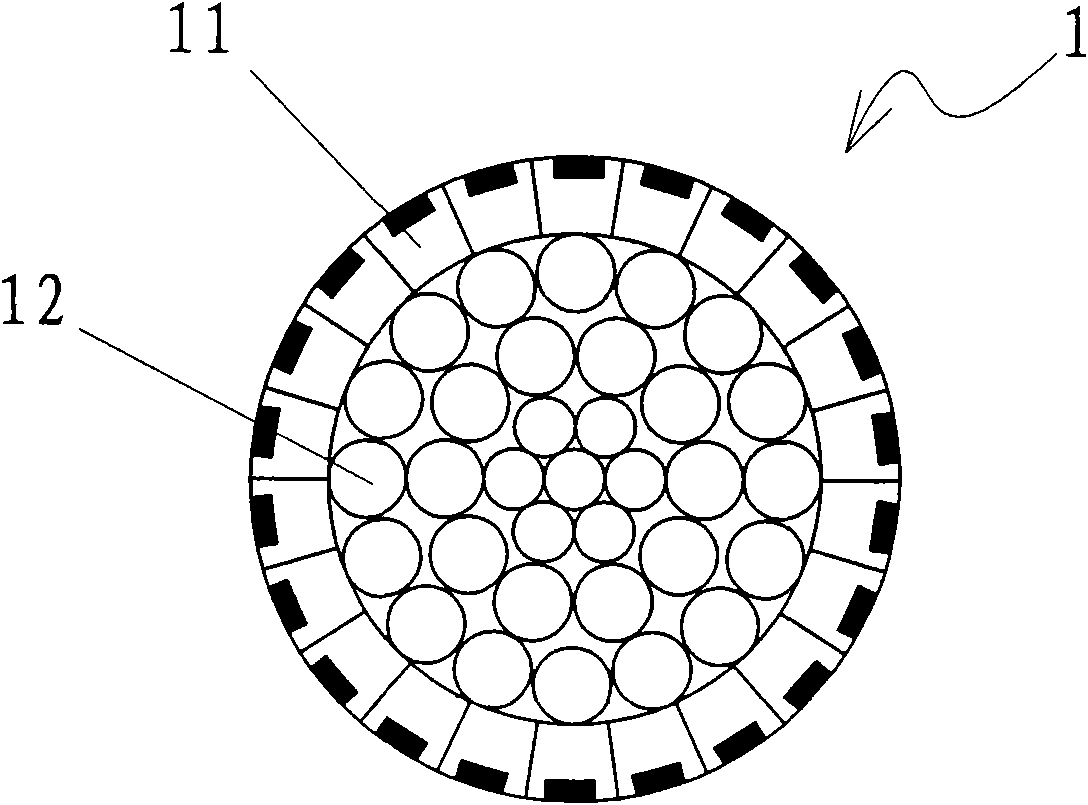

[0038] Such as Figure 1-Figure 4 As shown, the present invention provides a composite wire 1, the composite wire 1 is twisted by a plurality of monofilaments, wherein more than one monofilament is a heating monofilament 11, the heating monofilament 11 is at least partially The inner point is made of ferromagnetic material, and the other monofilaments are ordinary monofilaments 12 made of wire material. The heating monofilament 11 can generate heat when the surface temperature of the composite wire 1 reaches the freezing temperature, so that the surface of the composite wire 1 The temperature is maintained above the freezing temperature. In this way,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com