Broom and manufacturing method thereof

A production method and broom technology, which is applied in the direction of cleaning carpets, floors, and equipment, can solve the problems of time-consuming, high cost, and poor dust absorption effect, and achieve good adsorption effect, thorough cleaning, and simple production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

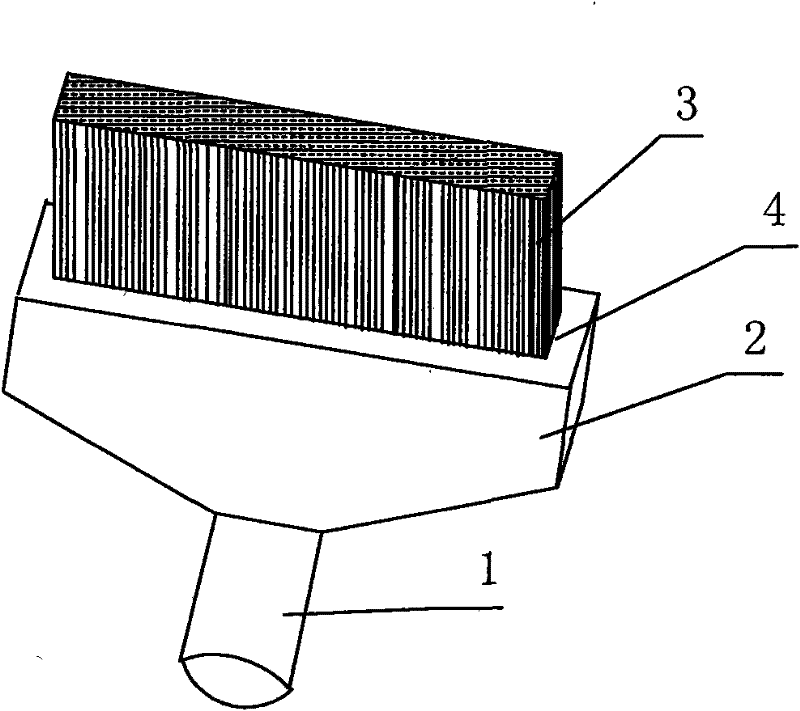

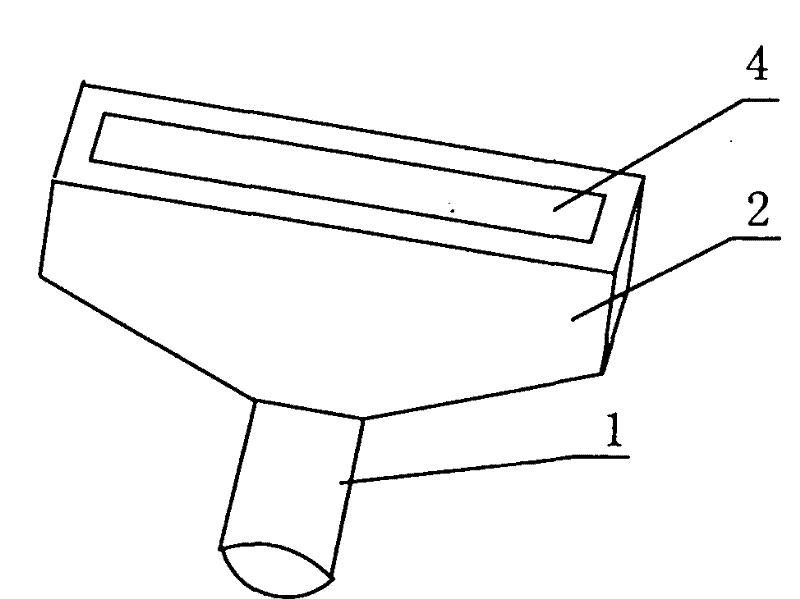

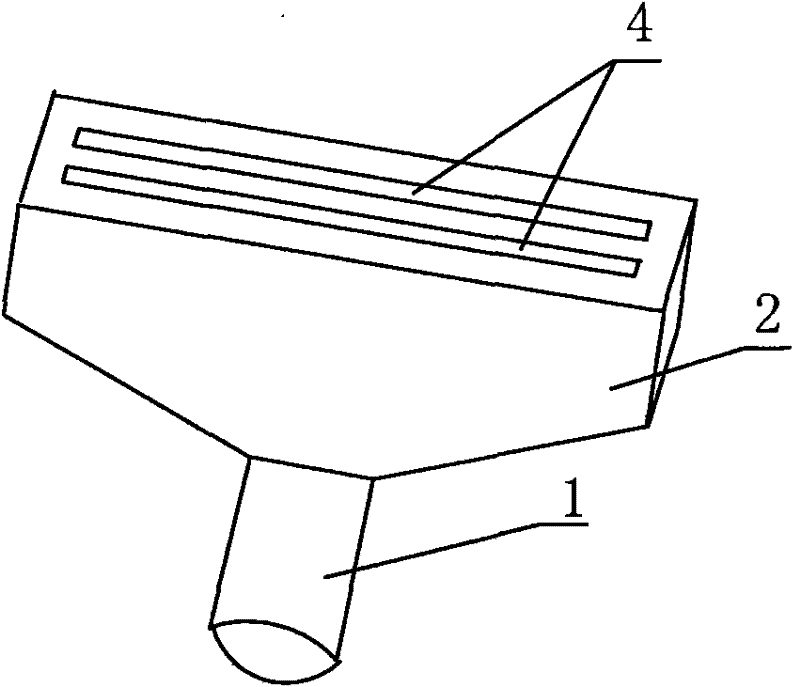

[0019] a broom such as figure 1 Shown: comprise broom handle 1, broom head 2 and the broom stick 3 that is fixed on the bottom of the broom head, the broom stick 3 is coconut palm silk or cocoa fiber, perhaps the broom stick 3 is made of coconut palm silk or cocoa fiber. The bottom of the broom head is provided with a "one"-shaped fixing groove 4 (such as figure 2 shown), the fixing groove 4 can also be in the shape of "two" (such as image 3 shown) or "back" font (such as Figure 4 shown). The broom strip 3 is integrally bonded in the fixing groove 4 . The connecting end of coconut palm or cocoa fiber and the bottom end of the broom head is glued together in sheet form, and the size of the end face of the connecting end is consistent with the caliber of the fixing groove.

[0020] The manufacturing method of the broom of the present invention comprises the following steps: 1. Open a fixed groove 4 with an appropriate depth on the bottom surface of the broom head 2; 6 (s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com