Floatation process of quartz sand

A quartz sand and process technology, applied in flotation, sieve, grid and other directions, can solve the problem that the production of quartz sand cannot meet the growing market, and achieve the effect of easy implementation, simple operation and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

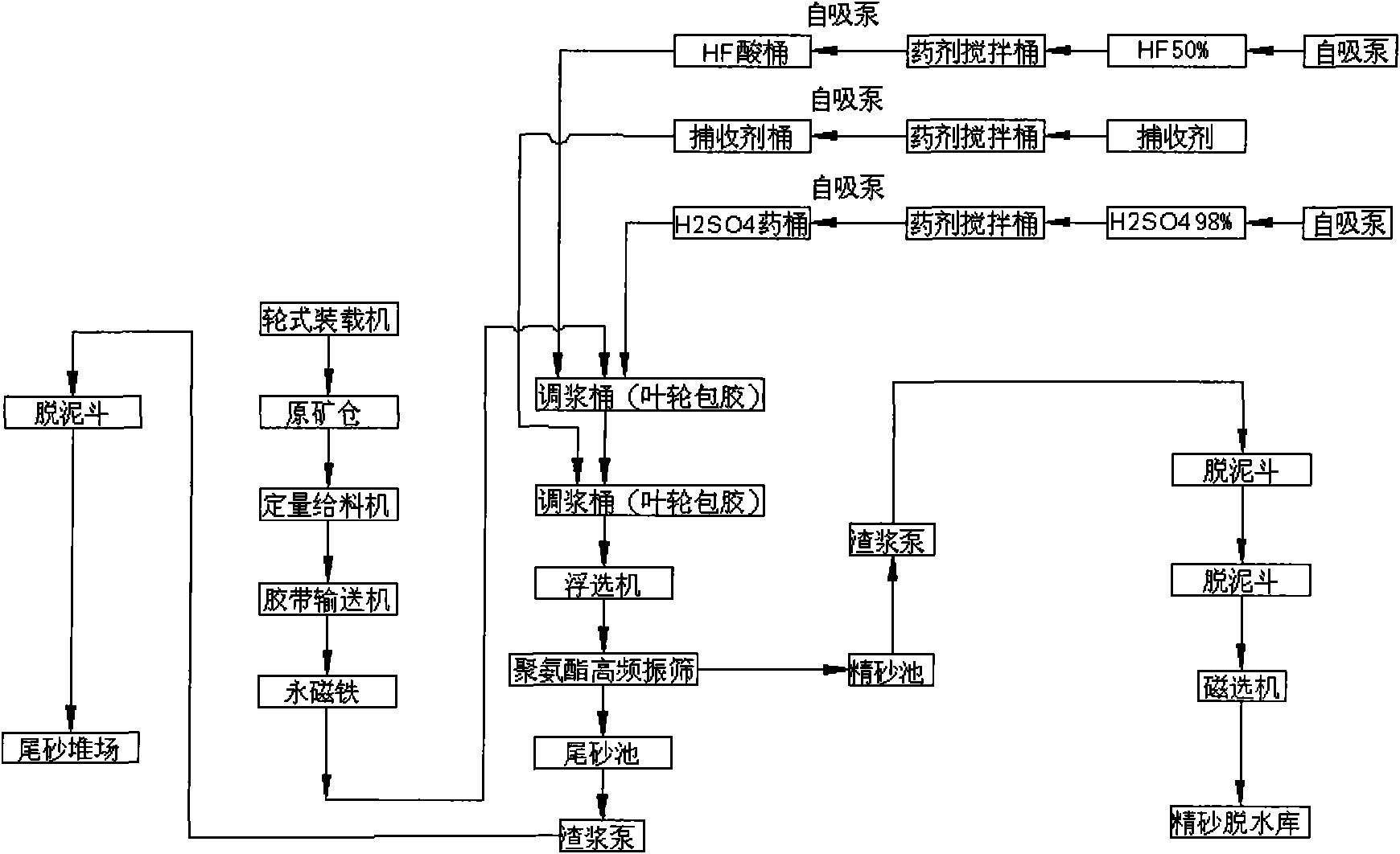

[0017] see figure 1 , a quartz sand flotation process, is characterized in that: the quartz sand raw material is loaded into the production silo by the loader, and then the quartz sand raw material is sent into the mixing impeller by the electronic belt feeder and the belt conveyor. In the first mixing tank, a permanent magnet is placed outside the first mixing tank. Before the quartz sand raw material is sent into the first mixing tank, the first step of iron removal is carried out by the permanent magnet. The first mixing tank is added with 4 -5%H 2 SO 4 solution or 4-5% H 2 SO 4 and HF solution, adjust the PH value in the first mixing tank to 3, and send the quartz sand raw material to form a quartz sand slurry; then send the quartz sand slurry into the second mixing tank that has been treated with the mixing impeller. At the same time, add the flotation agent to the second mixing tank for stirring, so that the quartz sand slurry and the flotation agent fully react unti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com