Cold precision forging tooth die for bevel gear

A bevel gear, cold precision forging technology, applied in the direction of wheels, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problem of insufficient service life of the lower mold core, increased cost of re-molding, broken teeth Damage and other problems, to achieve the effect of long service life, uniform force, easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

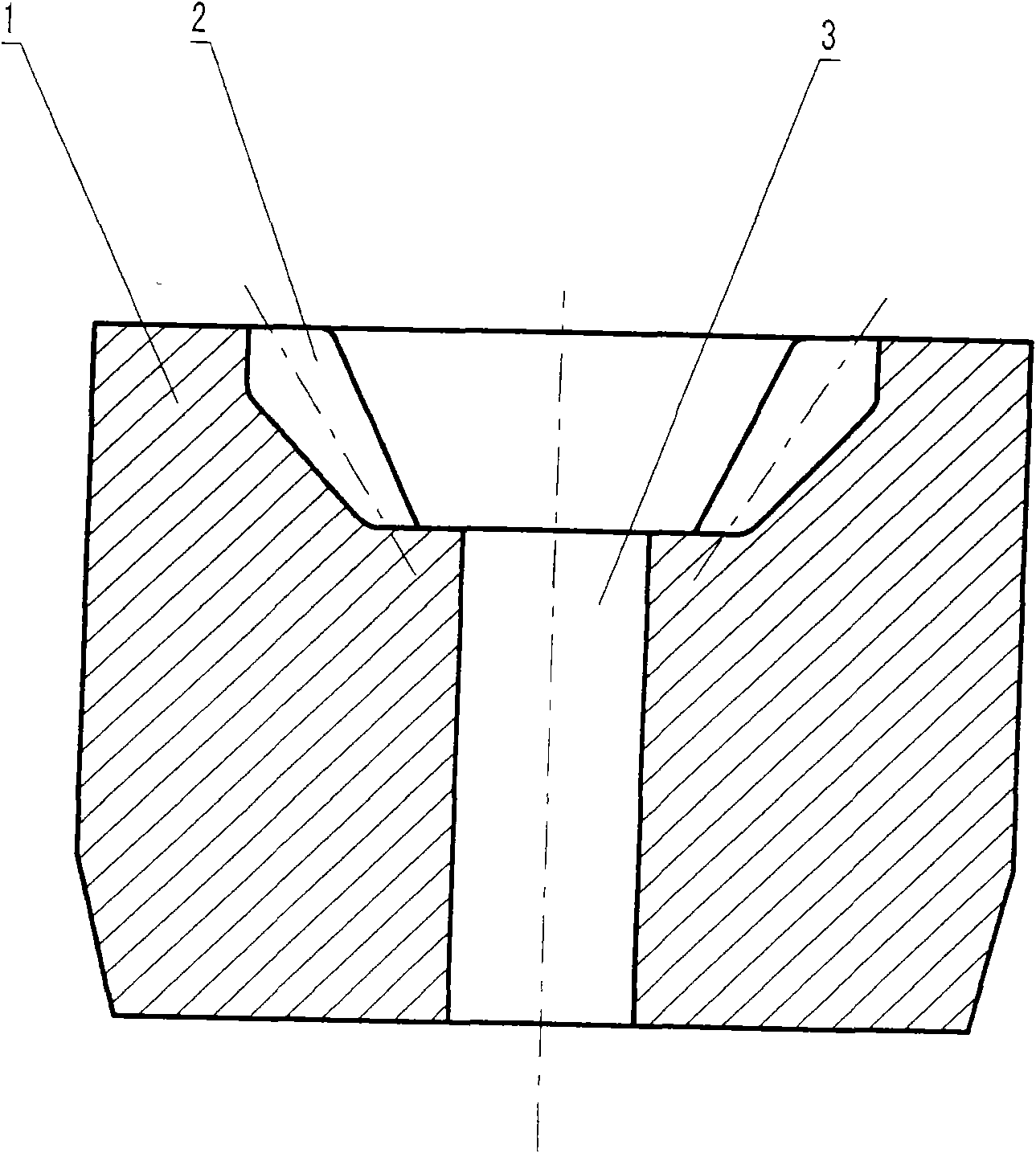

[0011] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments. The cold precision forging bevel gear tooth form mold shown in the accompanying drawing is the embodiment of cold precision forging the bevel gear of Volkswagen gearbox, and it includes a lower mold core 1, a bevel tooth mold cavity 2 and a circular through hole 3. The lower mold core 1 is disc-shaped, the upper and lower end faces are parallel to each other, and the vertical round through hole 3 in the middle communicates with the bevel-toothed mold cavity 2 above. The upper end surface of the lower mold core 1 is flat, and the conical-toothed mold cavity 2 is concave downward based on the upper end surface of the lower mold core 1 as a plane. In the present invention, the bevel-tooth-shaped mold cavity is all recessed in the lower mold core, and the overall structural strength is high, and the force is uniform, so that mold damage accid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com