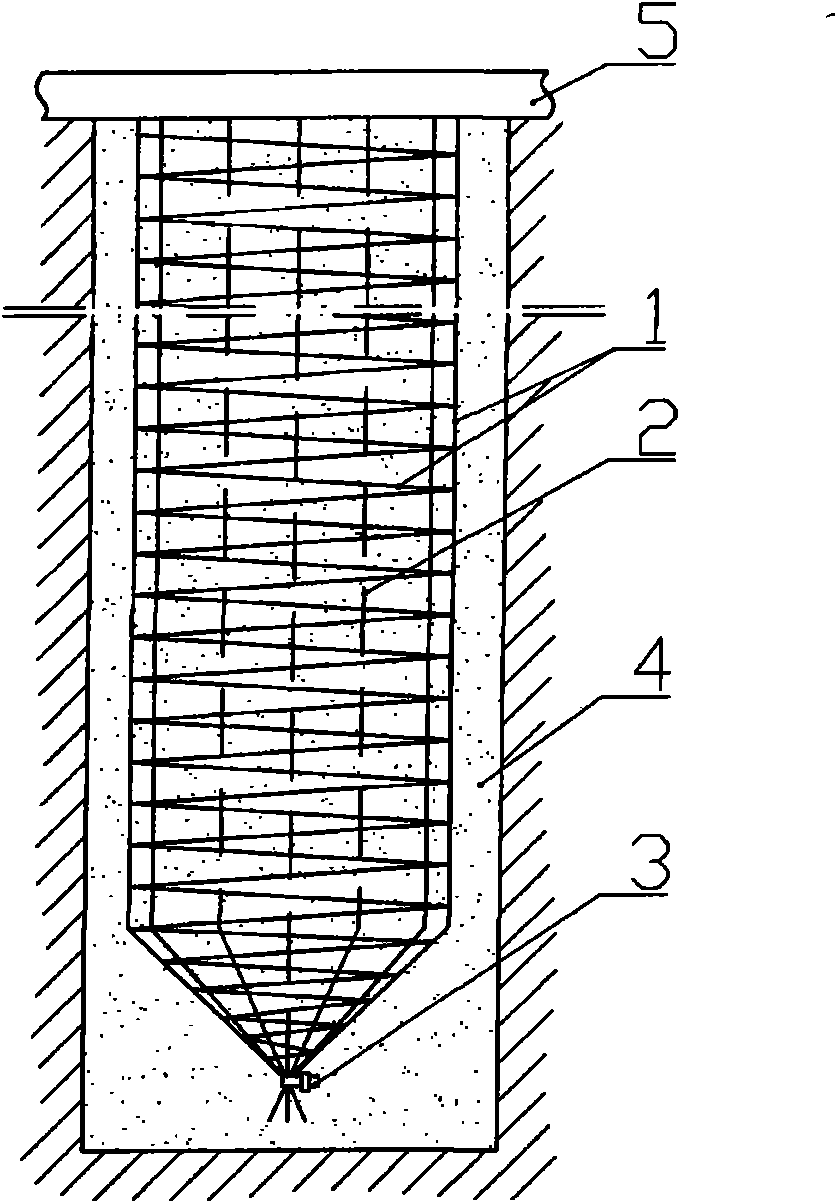

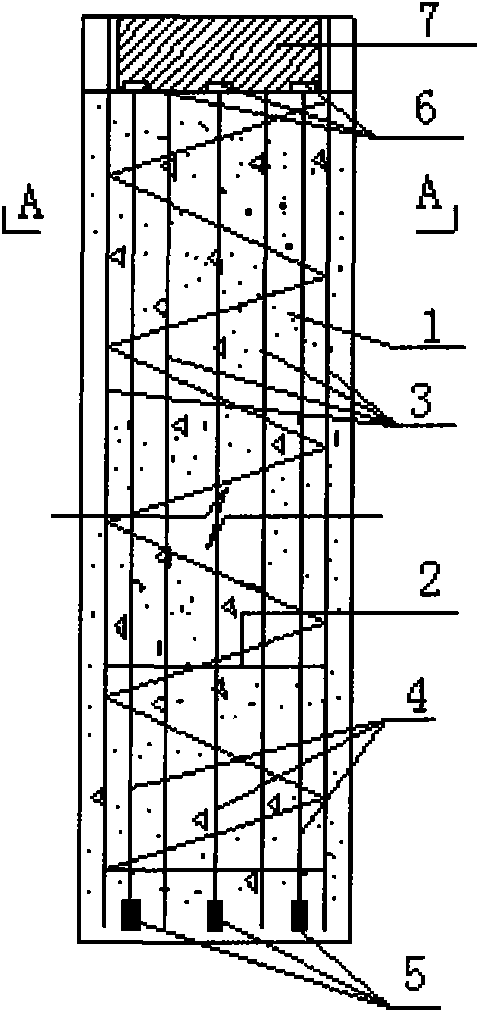

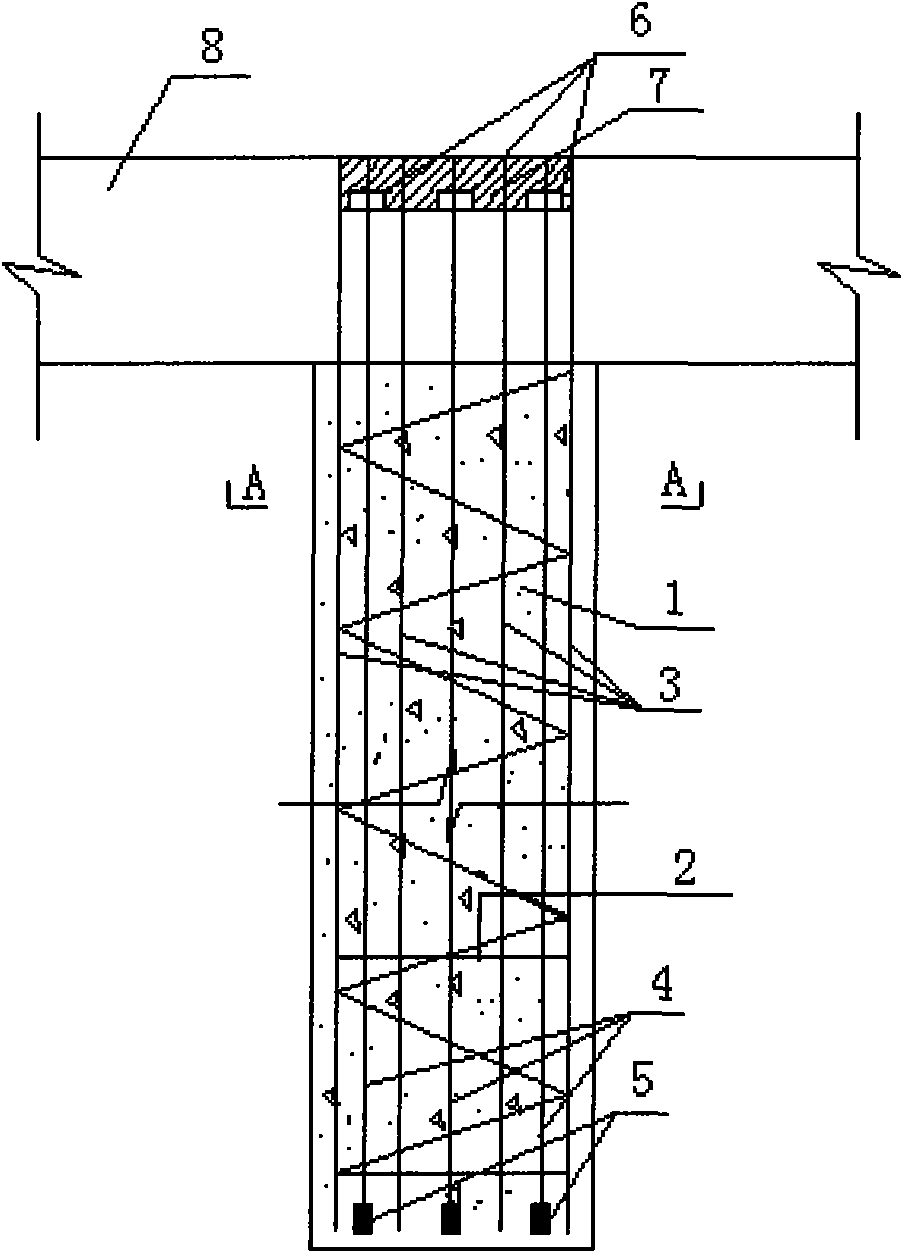

Post-tensioned prestressing cast pile and construction method thereof

A post-tensioning prestressing and construction method technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of high requirements for construction equipment, difficult to guarantee construction quality, and inappropriate long piles, etc., to improve structural safety. and durability, considerable economic and social benefits, and the effect of reducing the amount of steel and concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Taking more than 2,000 anti-floating cast-in-situ piles required for the 160,000 square meters of underground second-floor garages in the CBD center of Binhai New District, Tianjin City as an example, the application of the post-tensioned prestressed cast-in-situ pile technology of the present invention is introduced from two aspects of bearing capacity and crack resistance. Superiority. This project adopts bored anti-floating cast-in-situ piles, and its parameters are: pile diameter 700mm, pile length 37m, and the standard value of single pile pullout ultimate bearing capacity is 4200kN. The original reinforcement scheme: within the pile length range of 23m from the top of the pile to the lower part, configure the main reinforcement Stirrups φ8@200, arranged within the remaining 14m pile length The stirrup is φ8@200, the reinforcing bar is φ12@2000, and the reinforcement ratio ρ is 2.55%. It can be seen that the amount of reinforcement is large and uneconomical. Us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com