Improved adsorbent articles for disk drives

A technology for disk drives and products, applied in chemical instruments and methods, reducing physical parameters of carriers, other chemical processes, etc., and can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

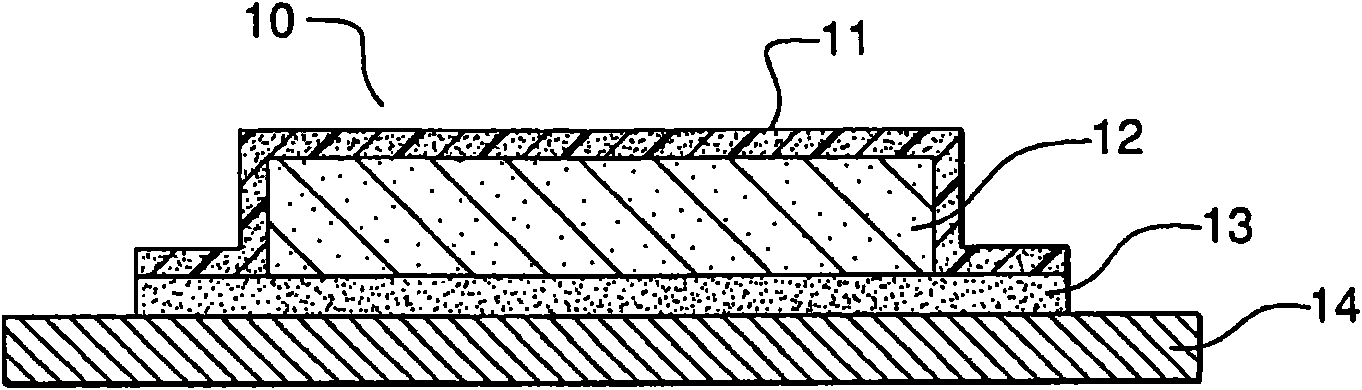

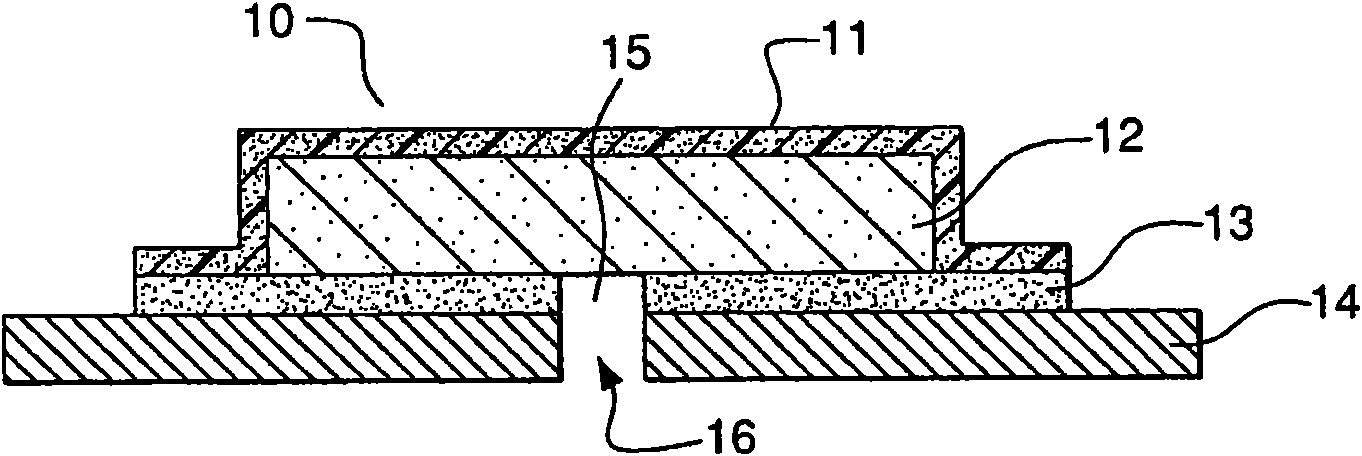

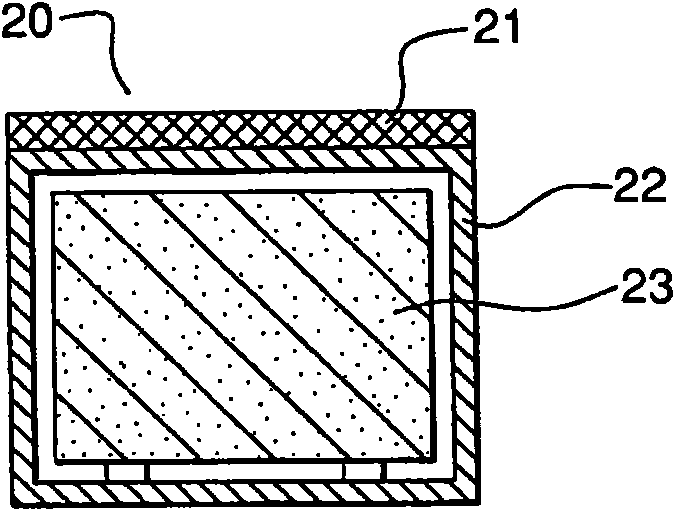

Method used

Image

Examples

Embodiment 1

[0106] Activated carbon with part number 3042 was obtained from Calgon Carbon Corporation. 100 grams of carbon are further processed to achieve oxygen-containing functional end groups on the surface of the carbon. The treatment process includes: soaking the activated carbon with a solution of 560 grams of ammonium persulfate and 100 milliliters of sulfuric acid in 1000 water for 2 hours, and then washing multiple times Remove residual solution on the carbon and dry. Wash or rinse with deionized water until the remaining reagents on the carbon are removed. Determination by elemental analysis and Boehm titration yielded results: 17.6% by weight of oxygen and 175.3 milliequivalents / 100 g total acid groups. The water weight adsorption and organic vapor weight adsorption tests were also performed, and the results were obtained: the moisture capacity of 25%RH-45%RH was 17.2% by weight, and the TMP capacity was 20.9% by weight. This process beneficially compares adsorbents used in d...

Embodiment 2

[0110] The absorbent felt VAF100 was purchased from Shanghai First Activated Carbon Fiber Co., Ltd. (Shanghai, China, 200436). The results of elemental analysis and Boehm titration are: 11.39% by weight oxygen and 77.4 meq / 100g total acid groups.

[0111] According to the water vapor weight adsorption and organic matter vapor weight adsorption tests, the adsorbent is determined, and the result is that the moisture capacity of 25%RH-45%RH is 22.2% by weight, and the TMP capacity is 23.8% by weight.

[0112] Table 2 reflects the moisture capacity of the example and the adsorption device taken out from the commercially available disk drive at the medium RH. Table 2 also shows that the oxygen content and acidity of the examples are increased compared with the known adsorption device.

[0113] Table 2

[0114]

Embodiment 3

[0116] The prepared adsorption assembly has the following characteristics: an adhesive is coated on both sides of a polyester film with a thickness of 0.003 inches. The adhesive is a high temperature acrylic pressure sensitive adhesive with a thickness of 0.0015 inches. This two-sided adhesive structure was obtained from Adhesives Research Company (Glenn Rock Pennsylvania).

[0117] Prepare 80% by weight activated carbon and 20% by weight PTFE absorbent core. The material mixture is a co-coagulant according to the method described in US Patent No. 4,985,296. The material was then kneaded into a dough and rolled with a metal rolling pin into a thick sheet about 350 mils thick, 5 inches long, and 3 inches wide. The sheet was heated to 60°C, and then cross-calendered into a belt eight consecutive times. The speed of all rolling downwards is approximately 1.52 meters per minute. The first two rolls used a nip setting of 150 mils, first along the x-axis and then along the y-axis. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com