Thickness controlling method and control system in periodicity thickness changing strip rolling process

A technology of thickness control and strip rolling, which is applied in the direction of control/regulation system, program control in sequence/logic controller, rolling mill control device, etc., and can solve the problems that cannot meet the requirements of thickness control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

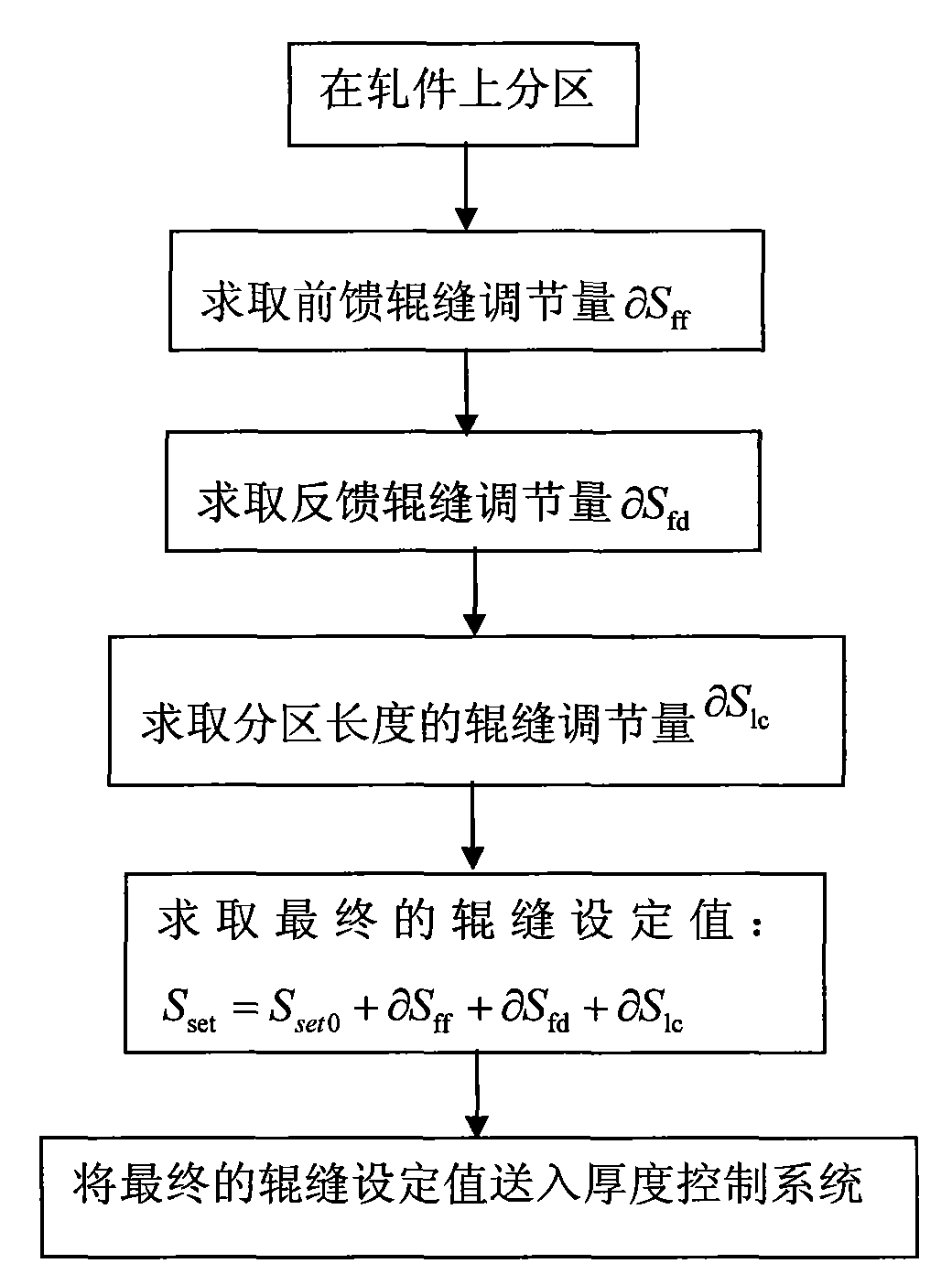

Method used

Image

Examples

Embodiment 1

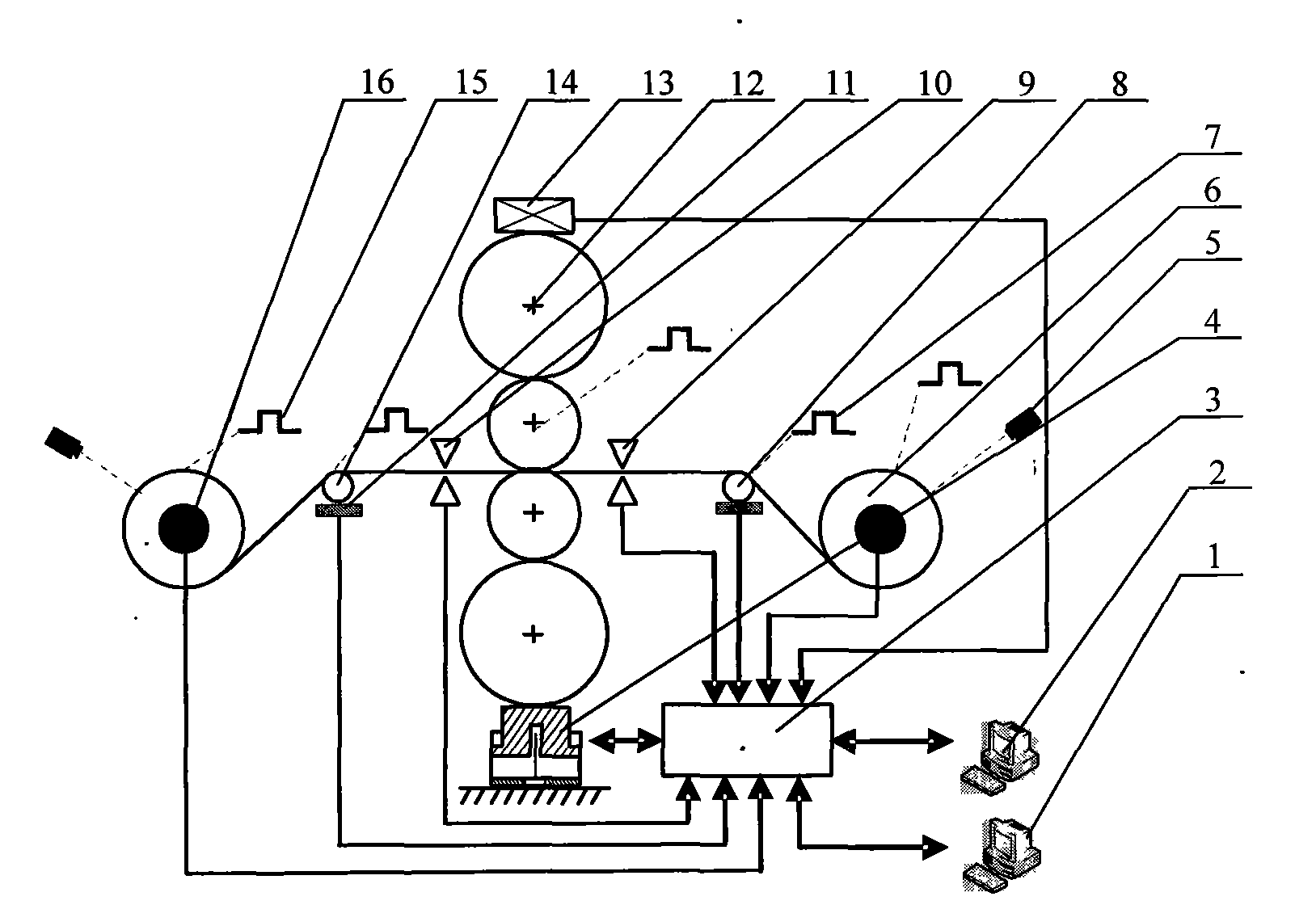

[0173] The relevant parameters of the system of the present invention are as follows:

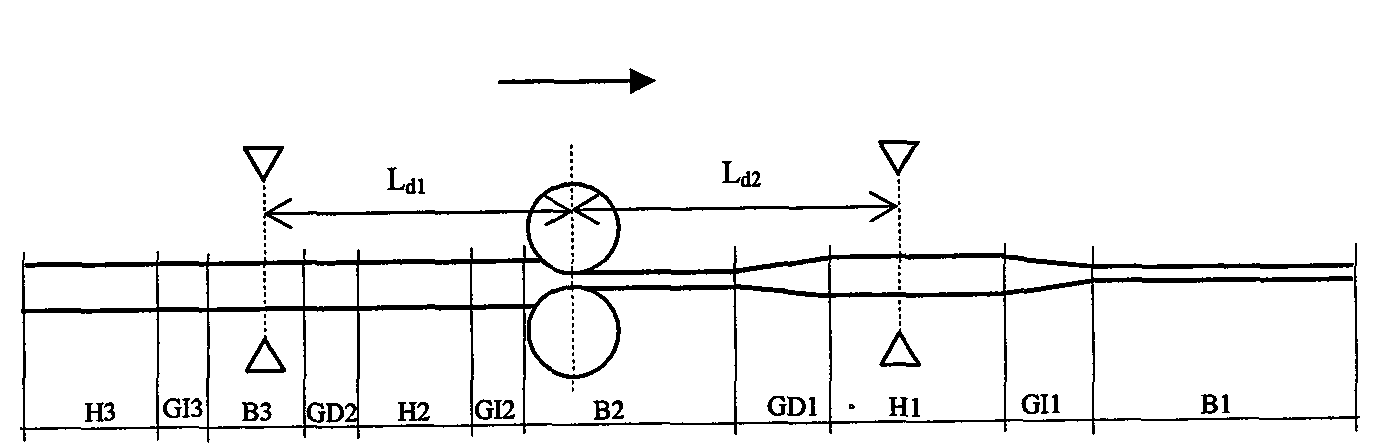

[0174] A 650mm four-high reversing rolling mill is adopted, and the distance between the entrance thickness gauge and the exit thickness gauge and the center line of the rolling mill is L d =1000mm, the two thickness gauges are X-ray thickness gauges, the measuring range is 0.1-5.0mm, the static accuracy 2σ=±0.10%, the repeatability is ±0.05%, the long-term stability is ±0.05% / 8h; the hydraulic cylinder The pressure is 22MPa, the response frequency of the hydraulic cylinder is 22Hz, and the step response time of 0.1mm is 31ms; the built-in displacement sensor of the hydraulic cylinder has a range of 100mm and a resolution of 0.001mm.

[0175] Incoming material status: Uniform thickness, steel type is IF, width 500mm, thickness 1.3mm.

[0176] Product size: the thickness of the thick zone is 1.2mm and the length is 300mm; the length of the transition zone is 50mm; the thickness of the thin ...

Embodiment 2

[0181] The relevant parameters of the system of the present invention are as follows:

[0182] A 650mm four-high reversing rolling mill is adopted, and the distance between the entrance thickness gauge and the exit thickness gauge and the center line of the rolling mill is L d =1000mm, the two thickness gauges are X-ray thickness gauges, the measuring range is 0.1-5.0mm, the static accuracy 2σ=±0.10%, the repeatability is ±0.05%, the long-term stability is ±0.05% / 8h; the hydraulic cylinder The pressure is 22MPa, the response frequency of the hydraulic cylinder is 22Hz, and the step response time of 0.1mm is 31ms; the built-in displacement sensor of the hydraulic cylinder has a range of 100mm and a resolution of 0.001mm.

[0183] Incoming material status: Uniform thickness, steel type is ST12, width 450mm, thickness 2mm;

[0184] Product size: thick zone thickness 1.5mm, length 200mm; transition zone length 100mm; thin zone thickness 0.8mm, length 200mm;

[0185] Rolling requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com