Direct-drive type feeding device of milling machine

A feeding device, transmission type technology, applied in electromechanical devices, feeding devices, milling machine equipment, etc., can solve the problems of small adjustable range, high manufacturing cost, inconvenient maintenance, etc., to reduce production costs, reduce failure rates, The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

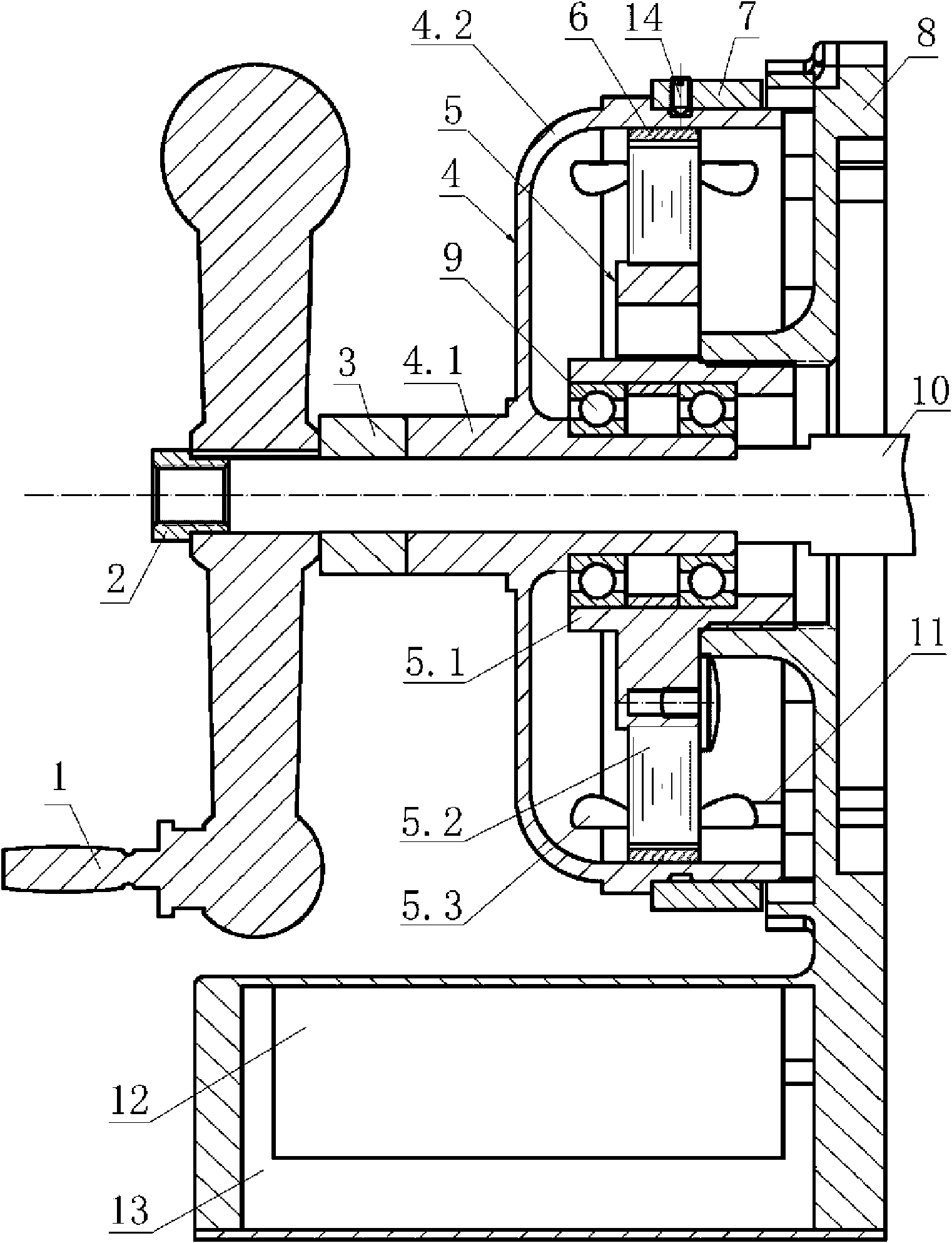

[0024] see example figure 1 As shown in the figure, this direct-drive feed device for a milling machine includes a low-speed motor that is driven and connected to the lead screw of the milling machine table and a motor controller that is connected to the low-speed motor. The low-speed motor is fixed on the motor base 8, and the low-speed motor is no Brushed DC servo motor, which includes a rotor 4 and a stator 5; the inner ring shaft sleeve 4.1 of the rotor is directly sleeved on the milling machine table screw 10 and is keyed to the milling machine table screw, and the outer shell 4.2 of the rotor is from the inner ring shaft of the rotor. The sleeve 4.1 extends out to form a cup-shaped rotor cover outside the stator 6 and ends at the outside of the motor base; the inner wall of the rotor shell 4.2 is glued with a permanent magnet 6; the inner ring sleeve 5.1 of the stator is sleeved on the rotor through the bearing 10 On the outside of the inner ring bushing, the stator coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com