Cutting device

A cutting device and component technology, applied in the direction of fine working devices, working accessories, stone processing equipment, etc., can solve the problem of device quality degradation and achieve the effect of preventing quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

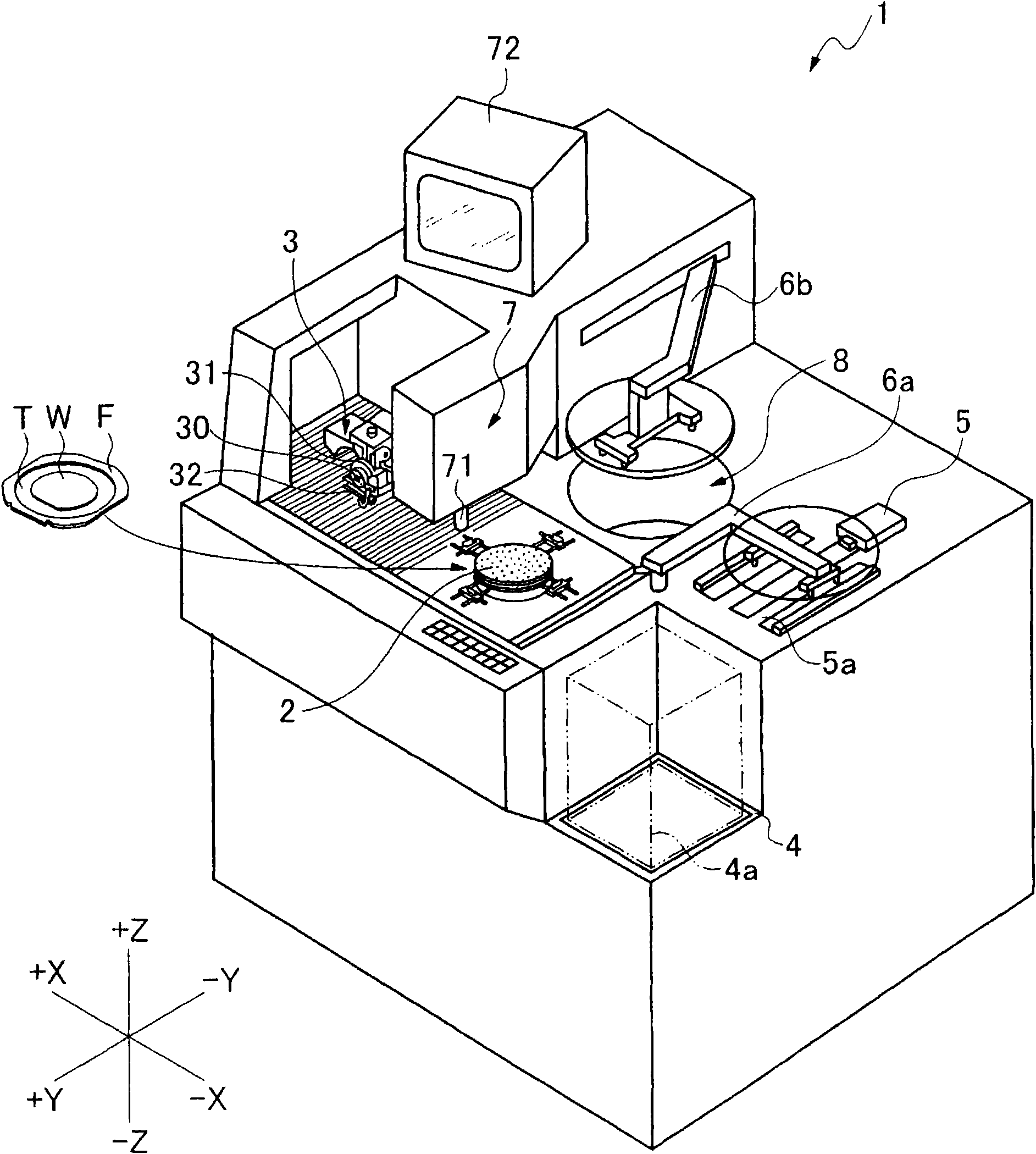

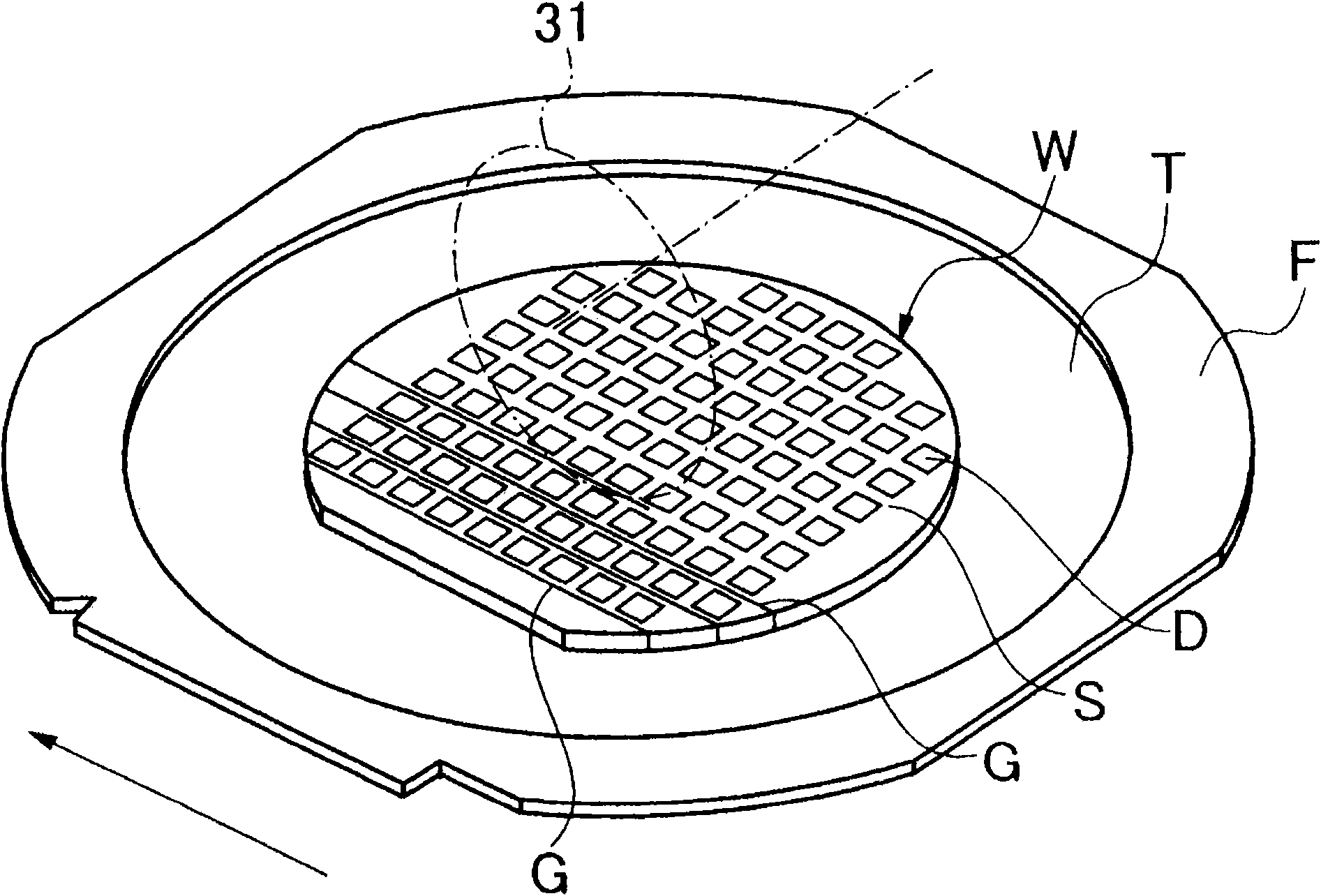

[0021] figure 1 The cutting device 1 shown is a device for cutting a wafer held on a chuck table 2 by a cutting member 3 . At the front of the cutting apparatus 1, there is a cassette loading area 4 where a wafer cassette 4a for storing wafers to be cut is placed. Further, a loading / unloading member 5 for loading and unloading wafers from and into the wafer cassette 4 a is disposed on the rear side of the cassette loading area 4 .

[0022] A temporary storage area 5 a is provided between the cassette loading area 4 and the loading / unloading member 5 as an area where wafers are temporarily loaded. In addition, a first transfer member 6 a for transferring a wafer between the temporary storage area 5 a and the chuck table 2 is disposed near the temporary storage area 5 a.

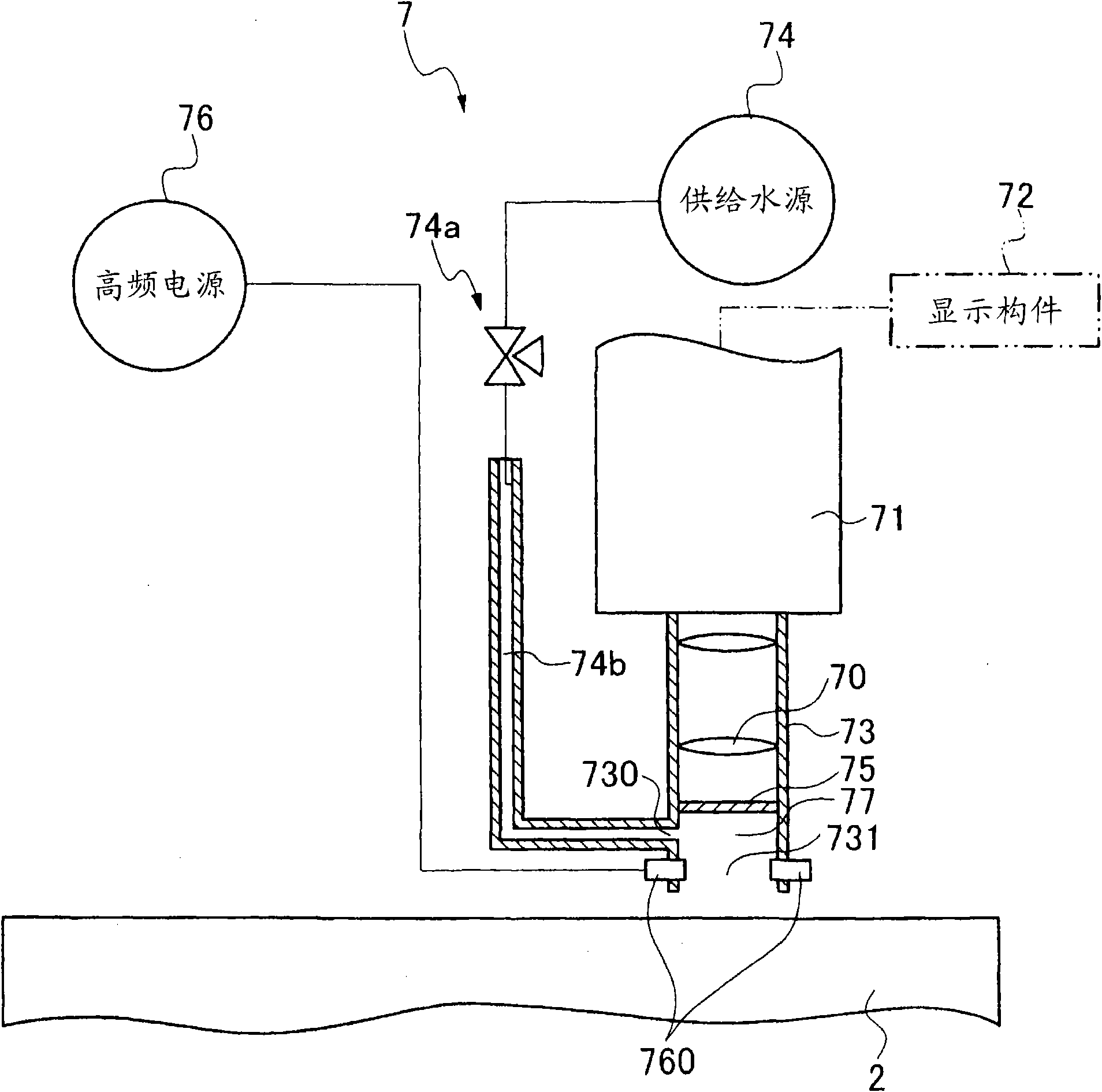

[0023] The chuck table 2 is movable in the X-axis direction, and an alignment member 7 for imaging the wafer held on the chuck table 2 to detect a region to be cut is disposed above the movement path of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com