Self-locking lifting hook

A hook and self-locking technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of high labor costs and hidden dangers in production safety, and achieve the effect of avoiding manual support, rational use of functions, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

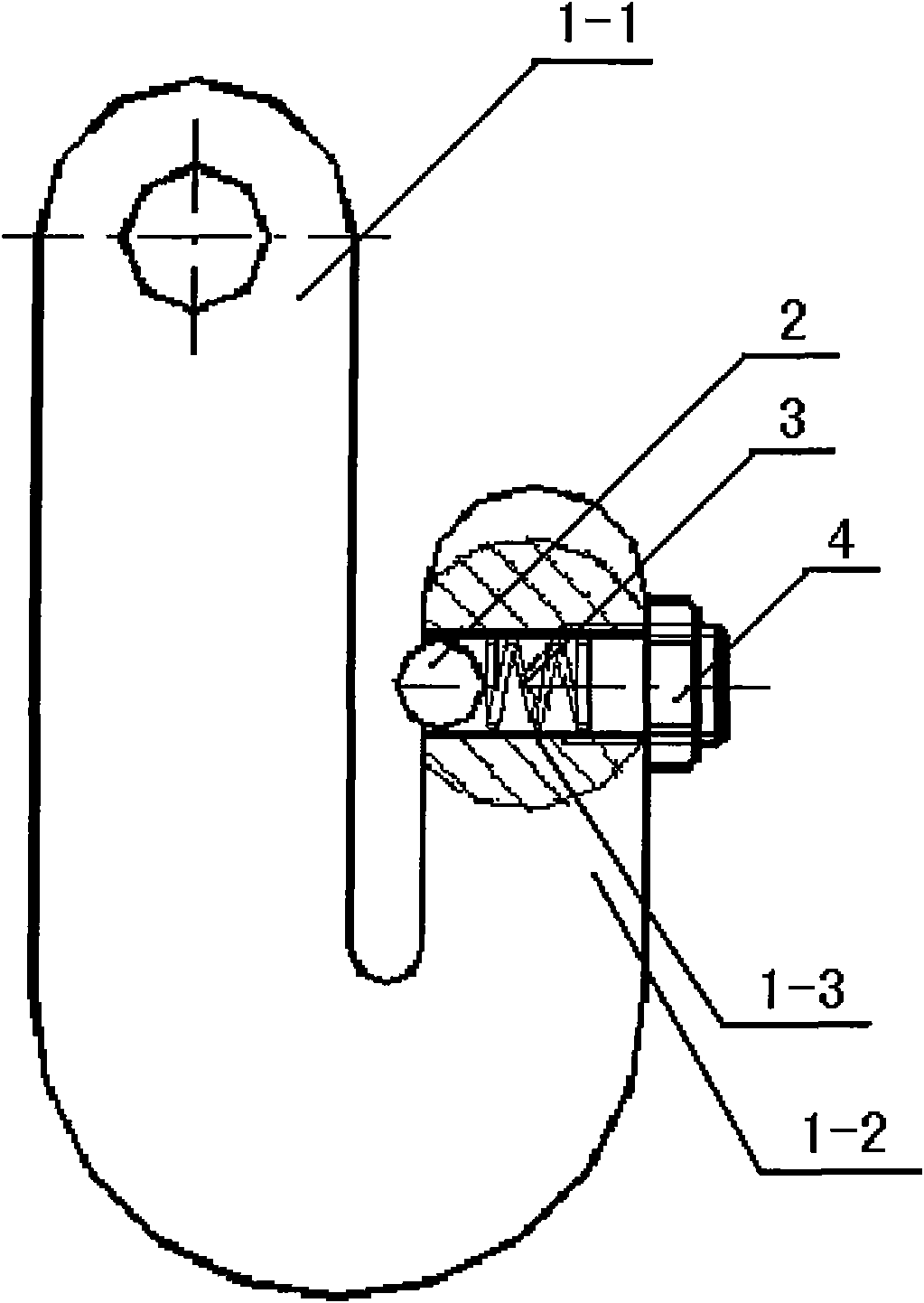

[0010] This self-locking hook as shown in the figure has a transverse groove 1-3 at the upper end of the auxiliary side hook body 1-2 of the hook main body 1-1, and a steel ball 2 and a spring 3 are housed in the transverse groove 1-3. The inner diameter of the transverse groove 1-3 is smaller than the ball diameter of the steel ball 2, so that the position of the steel ball is limited to the inside of the groove without dislocation. The adjusting bolt 4 is located outside the slot. The tension of the spring is adjusted by adjusting the bolt, so as to generate thrust on the steel ball.

[0011] When this kind of self-locking hook is in use, the operator (single person) puts the hook into the suspension ring from bottom to top, so that the inner hook bottom of the suspension hook contacts the suspension ring. At this moment, the steel ball 2 that is located on the main body 1-1 of the suspension hook is first squeezed into the groove, and the suspension hook and the suspension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com