Molten iron pretreatment spraying gun

A technology of molten iron pretreatment and spray gun, which is applied in the field of tools, can solve the problems of increased operation difficulty and uneconomicalness of the refractory layer, and achieve the effect of sufficient and uniform mixing, good effect and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

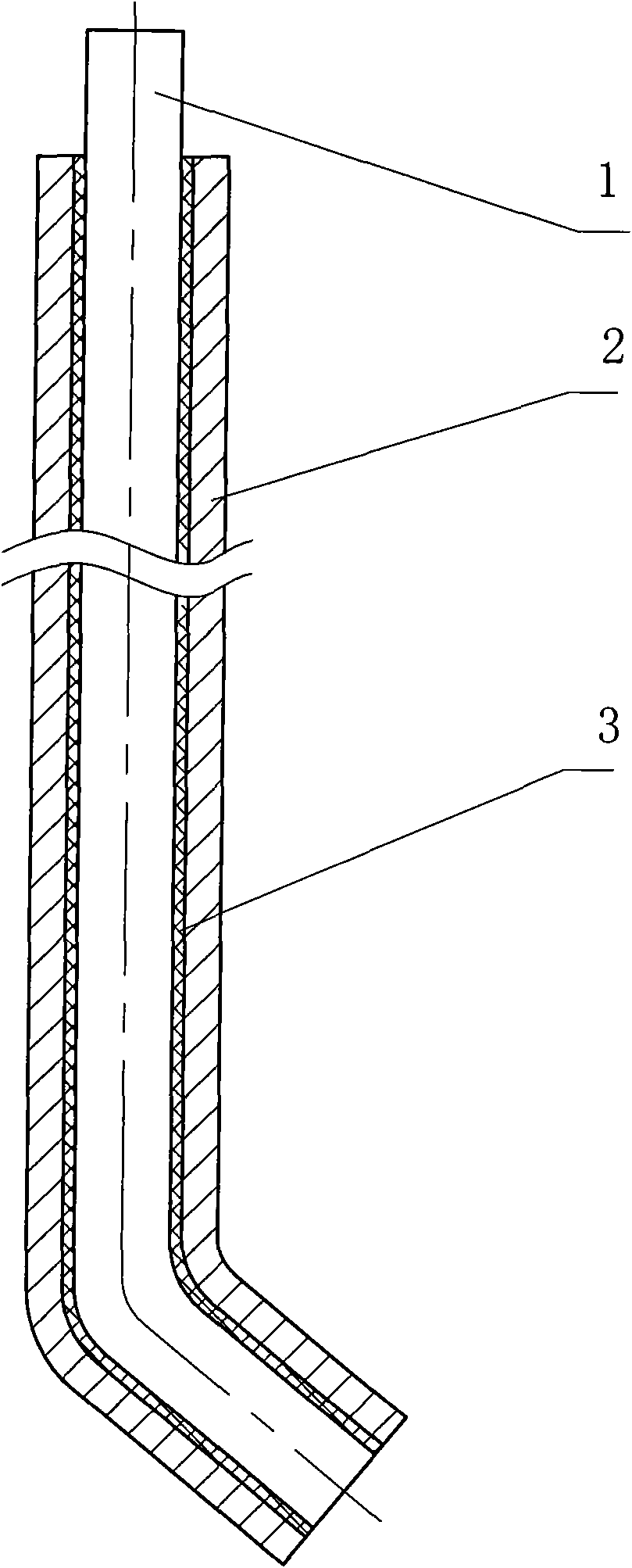

[0031] figure 1 Shown is a molten iron pretreatment spray gun, which is composed of a steel pipe 1 wrapped with a refractory material layer 2, and a layer of steel wire mesh 3 is wrapped between the steel pipe 1 and the refractory material layer 2. The spraying end of the steel pipe of the spray gun is bent .

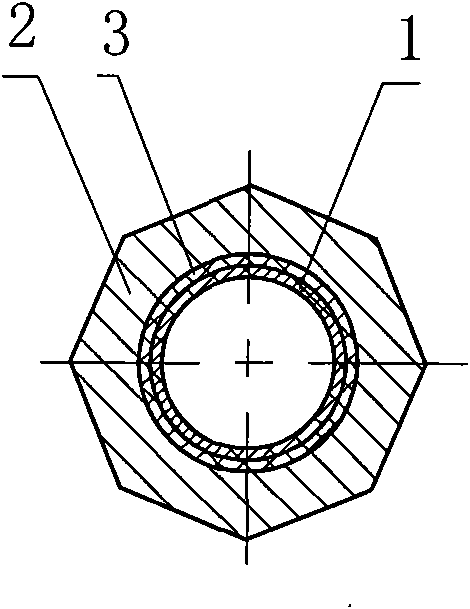

[0032] image 3 , 4 , 5 respectively show the cross-section of the spray gun refractory material layer 2 is octagonal, quadrilateral, hexagonal structural views. The invention achieves the expected purpose, reduces the weight of the spray gun, reduces the production cost, and at the same time reduces the height of the workshop in the hot metal pretreatment area and the requirements for the lifting device, prolongs the service life, and improves the effects of desulfurization, dephosphorization and desiliconization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com