Steel casting GS24Mn6

A technology of steel castings and elements, applied in the field of steel castings manufacturing, can solve the problems of impact toughness decline, impact toughness requirements are difficult to meet, grains cannot meet tempered sorbite grain size requirements, etc., to achieve broad development Prospects, effects of improving welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

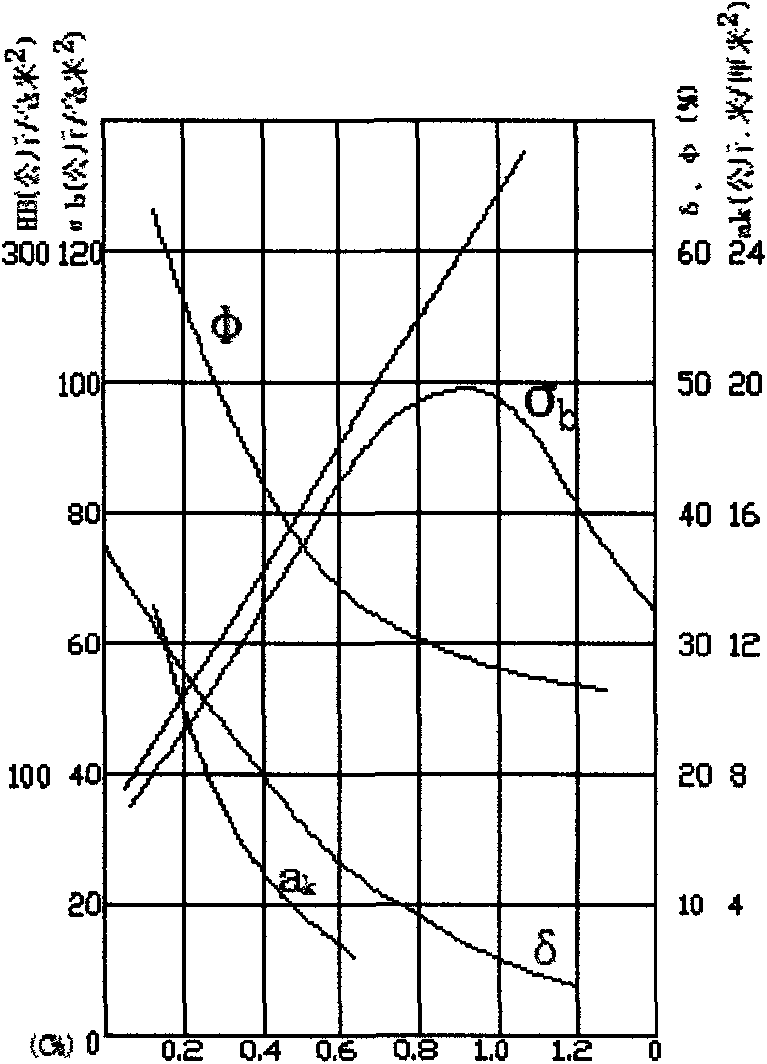

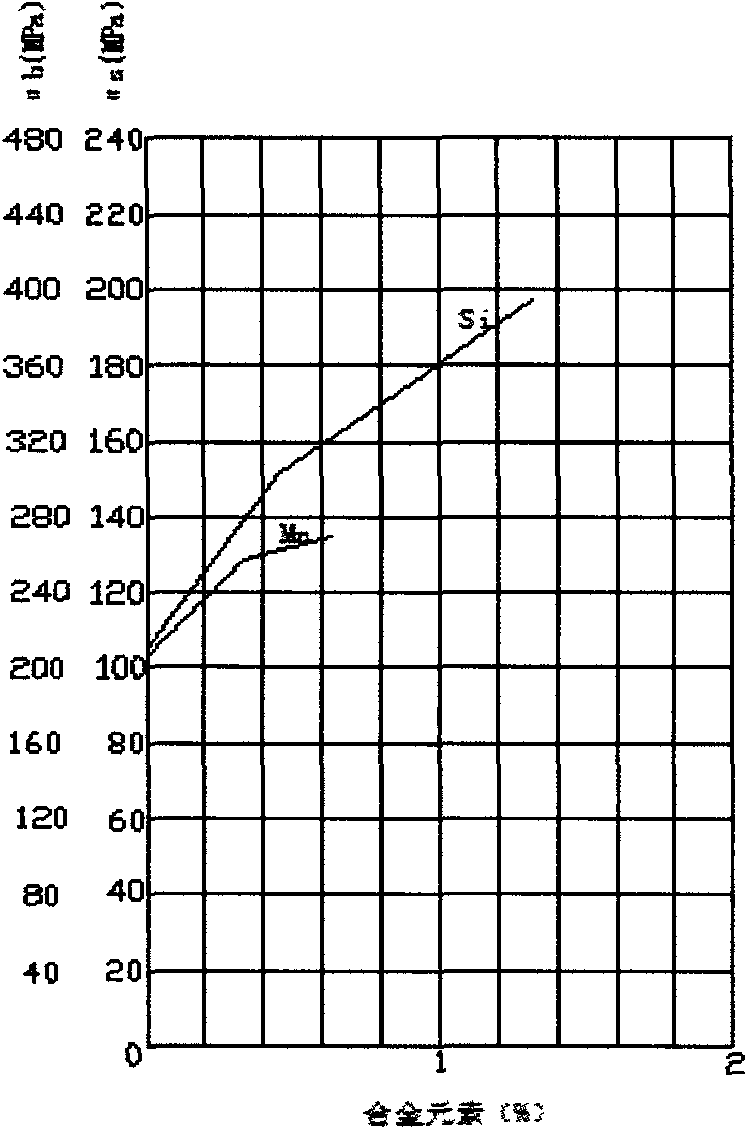

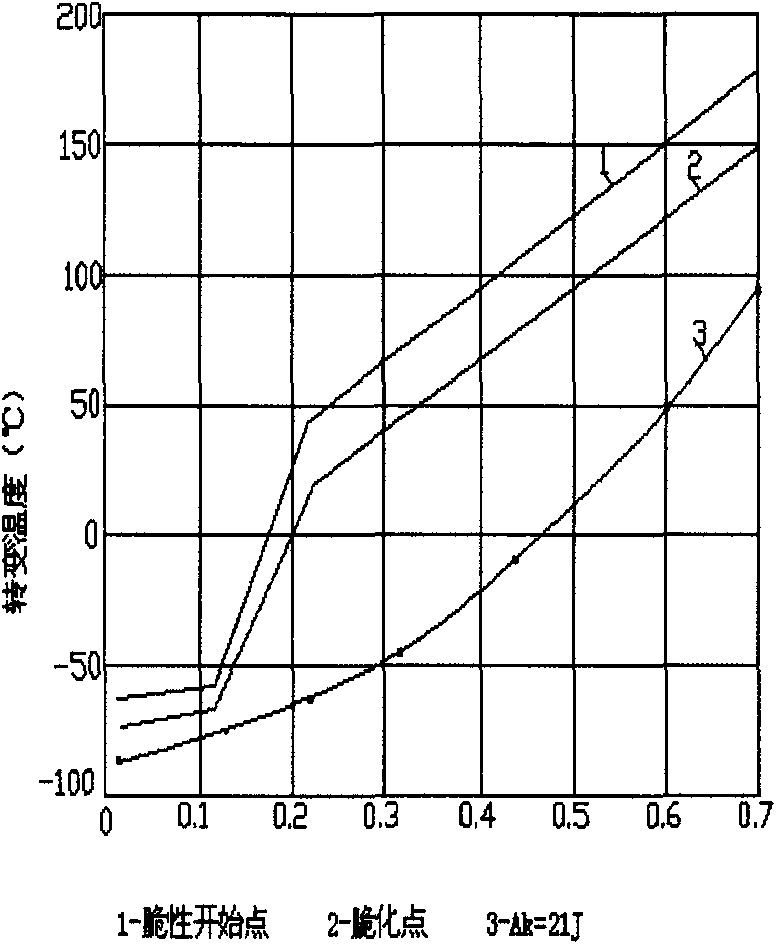

[0028] Embodiment 1: From the corresponding relation of chemical composition and mechanical property, strength property index is directly proportional to the content of carbon, silicon, manganese (see figure 1 , figure 2 ),from figure 1 The effect of carbon content on the strength of steel can be seen that the carbon content has a great influence on the strength. With the increase of carbon content, the tensile strength and hardness index increase obviously, and the plasticity and toughness index decrease accordingly. The low temperature toughness of castings decreased, the ductile-brittle transition temperature increased (see image 3 ); although when the silicon content is less than 0.60%, it has little effect on the crystal grains and has little effect on the impact toughness (see Figure 4 ), but with increasing silicon content, the effect on the ductile-brittle transition temperature is even greater than that of carbon (see Figure 5 ); manganese can play a strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com