Wall-through connection terminal board

A terminal block and terminal technology, applied in the direction of connection, conductive connection, electrical components, etc., can solve the problems of increasing the number of molds, prolonging the production cycle, increasing manufacturing costs and management costs, etc., to improve safety, avoid short circuits or The effect of igniting fire and strengthening firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

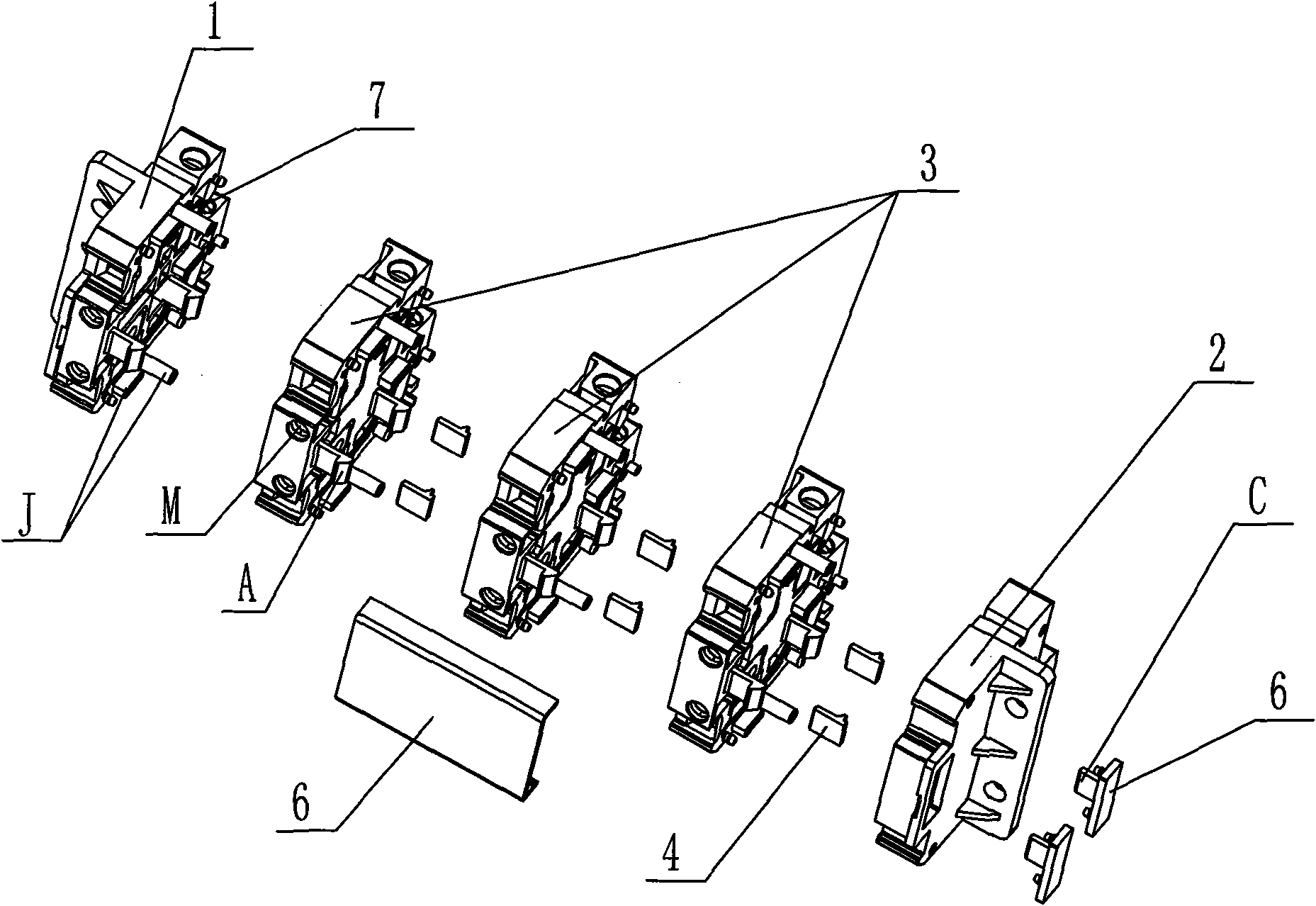

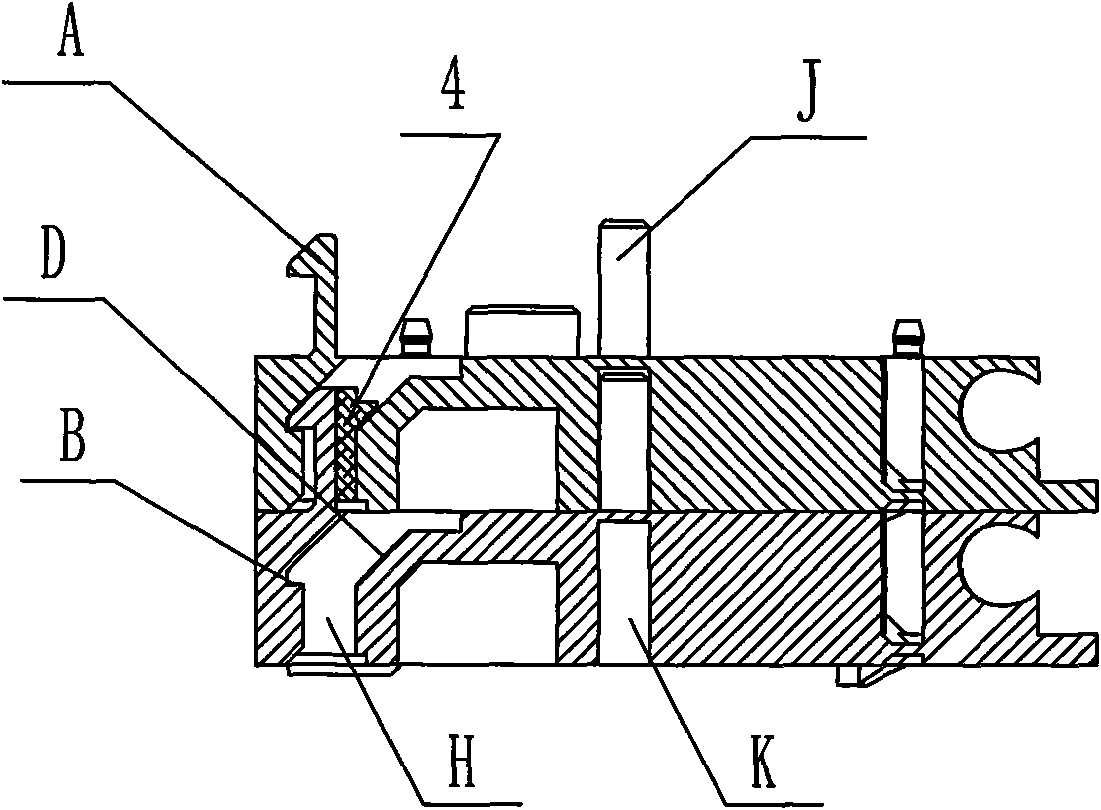

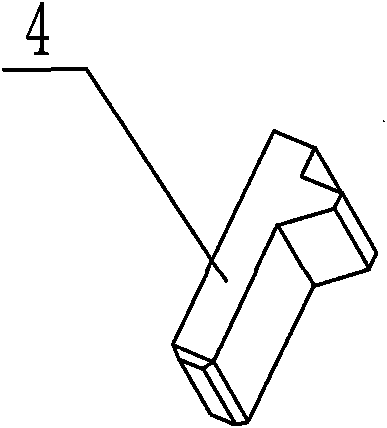

[0021] like Figure 1-2 As shown, the first specific embodiment of the present invention is: a through-wall terminal block, which is composed of a front end plate 1, a rear end plate 2 and a plurality of terminal blocks 3. In this embodiment, a total of Three pieces of terminal blocks 3 with the same structure, in actual use, any number of terminal blocks 3 can be set as required, protruding hooks A are arranged on the front panel 1 and the front of each terminal block 3, the hooks A is L-shaped; on the back of the rear end plate 2 and each piece of terminal block 3, a connecting hole H corresponding to the hook A is provided, and on the side wall of the connecting hole H, a matching hook A is provided. Hanging table B, hanging table B is a concave table surface sunken in the wall of the connecting hole H, the hook A of the front plate 1 can be buckled on the hanging table B of the adjacent terminal block 3; the hook A of each terminal block 3 Can be buckled on the hanging pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com