Printed circuit board before being formed and cut and manufacturing method thereof

A technology of printed circuit boards and circuit boards, which is applied in the direction of printed circuit components, electrical connection formation of printed components, electrical connection of printed components, etc., can solve problems such as gold finger peeling, and achieve the effect of avoiding gold finger peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

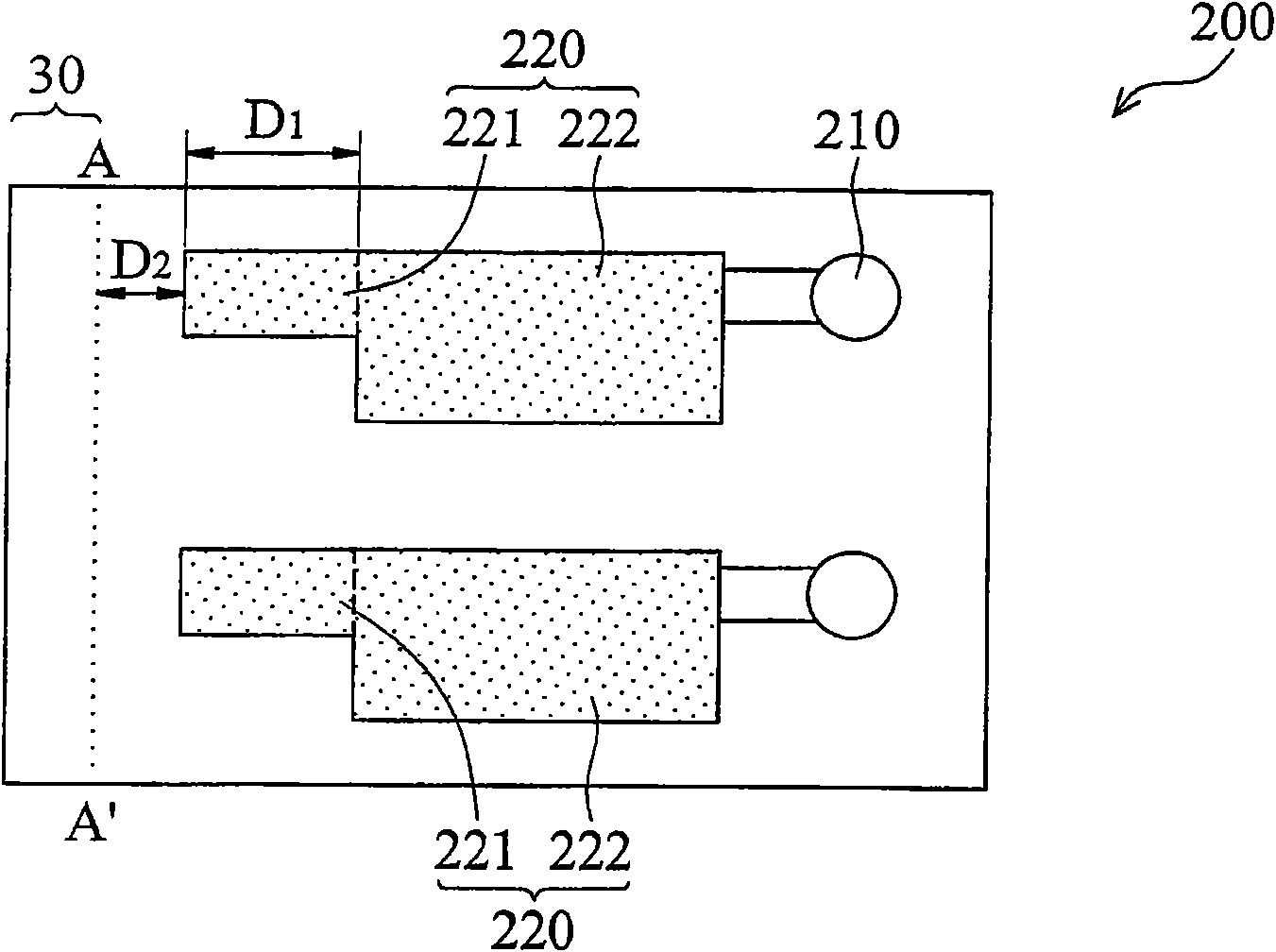

[0029] The invention provides a printed circuit board before forming and cutting, please refer to Figure 2A , including a circuit board 200 with the outer circuit, wherein the circuit board 200 exposes the circuit connection part 210 for connecting a plurality of gold fingers 220, and the gold finger 220 includes a protruding part 221 and a main part 222, and has a concave section form (see Figure 2B , side view of the circuit board), the length D1 of the protruding portion 221 is generally about 2 to 10 mils, the length D1 can be adjusted according to actual needs, and is not limited to this range. In addition, a forming path 30 ( AA′ is the boundary of the molding path) extending along the edge of the circuit board 200 adjacent to the protruding portion 221 of the golden finger. The main feature of the circuit board 200 is that there is a distance D2 between the gold finger protruding portion 221 and the forming path 30 , and the distance D2 is greater than 2 mils, prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com