Processing production line and processing method of steel bar thread for connection of straight steel bar thread machine

A mechanical connection and thread processing technology, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, can solve the problems of low work efficiency, high labor intensity of workers, and increased risk of bumping in processing operations, so as to improve the quality of thread processing, The effect of improving production efficiency and reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

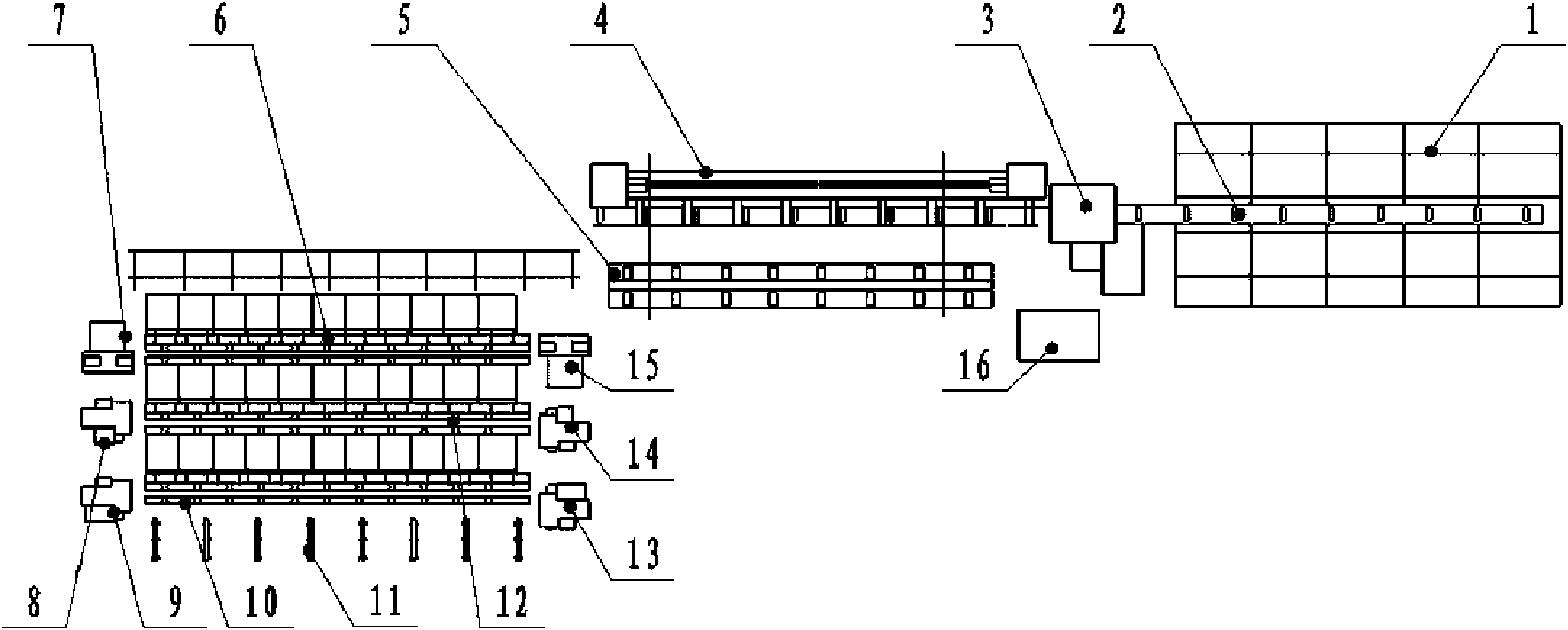

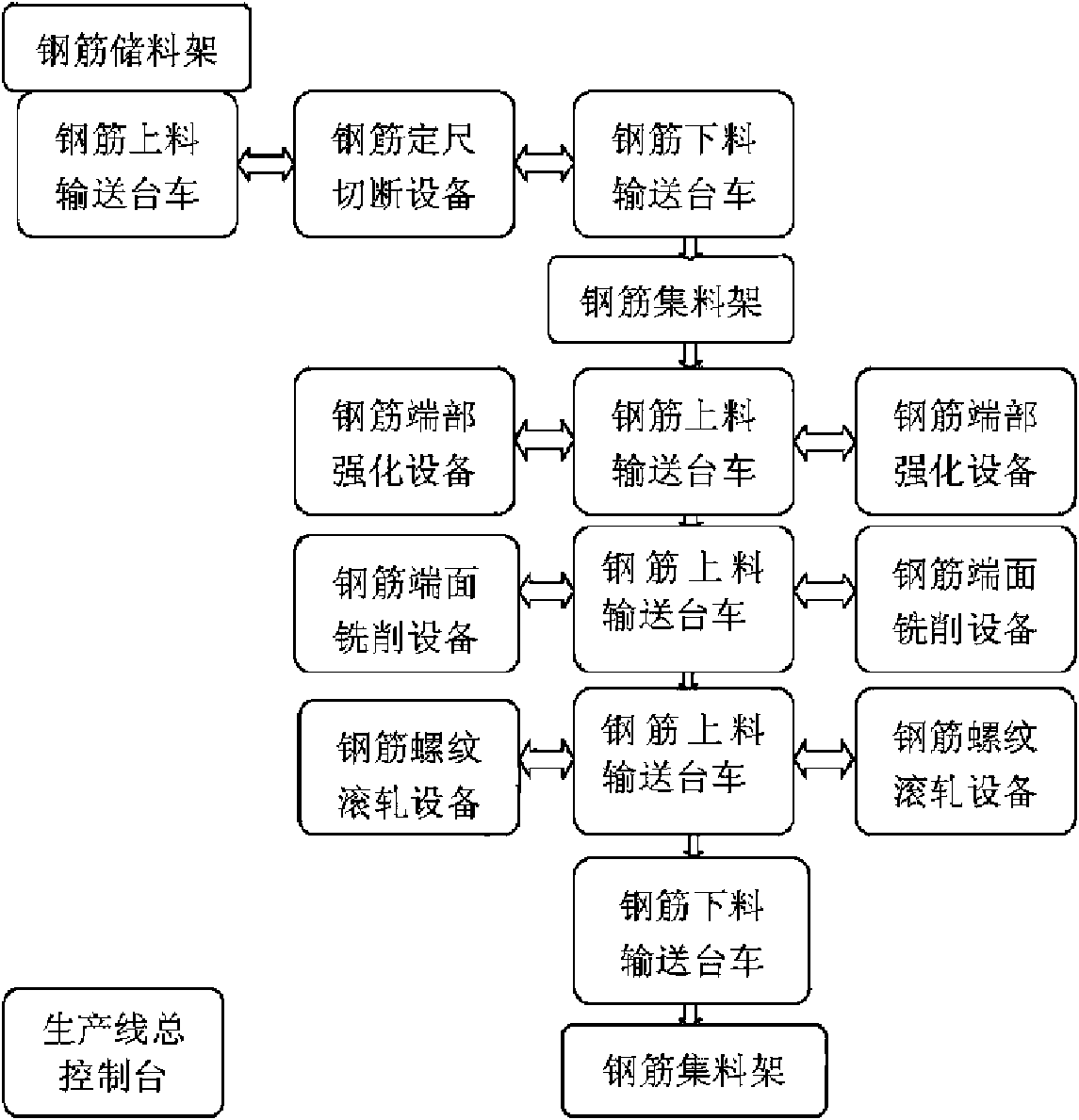

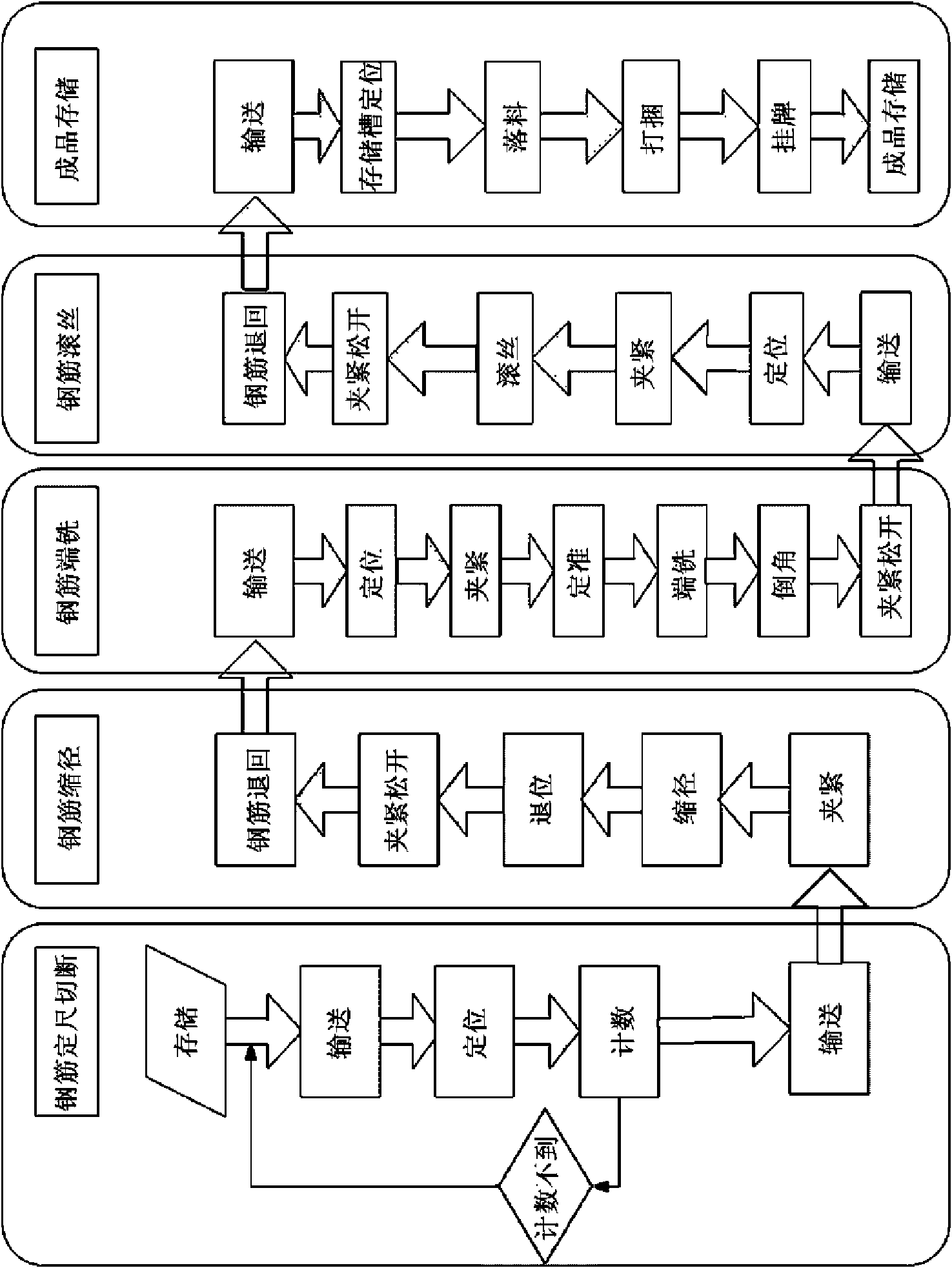

[0036] Examples see figure 1 , figure 2 As shown, the steel bar thread processing production line equipment for straight steel bar straight thread mechanical connection consists of steel bar cut-to-length equipment 3, two end strengthening equipment 7, 15, two end face milling equipment 8, 14, and two thread rolling equipment 9, 13, and the steel bar conveying trolley located between the above-mentioned equipments are connected into a production line, the control systems of the above-mentioned steel bar conveying trolley, steel bar fixed-length cutting equipment, end strengthening equipment, end face milling equipment, and thread rolling equipment are all connected with the overall The console is connected to 16; the position sequence of the production line equipment is:

[0037] The first station is steel bar cut-to-length: before and after the steel bar cut-to-length equipment 3 are respectively equipped with a steel bar shearing feeding and conveying trolley 2 and a steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com