Externally connected control system of in-mould laminating special injection molding machine and method thereof

A technology of injection molding machine and control system, which is applied in the field of external control system of special injection molding machine for in-mold lamination, can solve the problems of large space occupation, poor openness and high cost, and achieve the effect of saving space and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

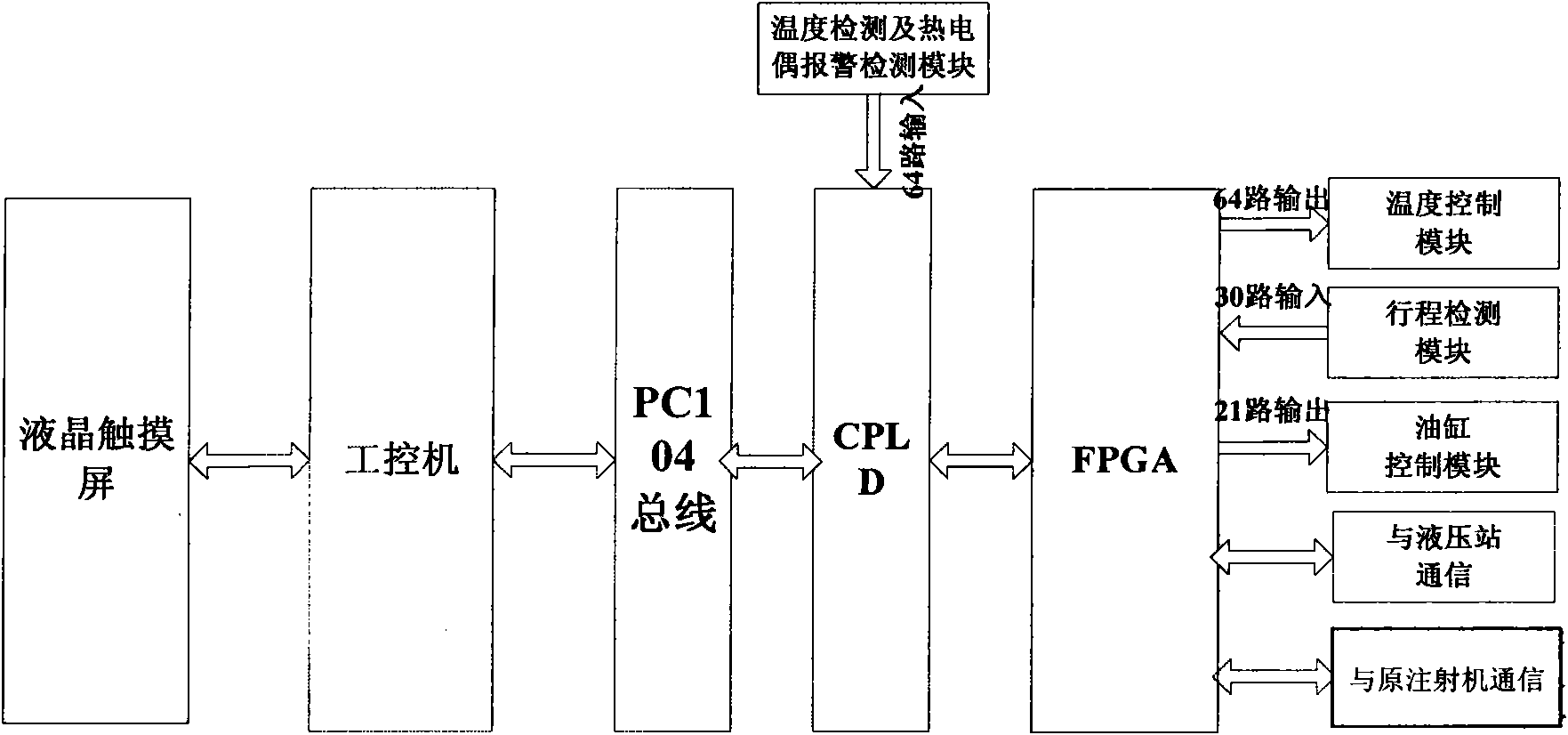

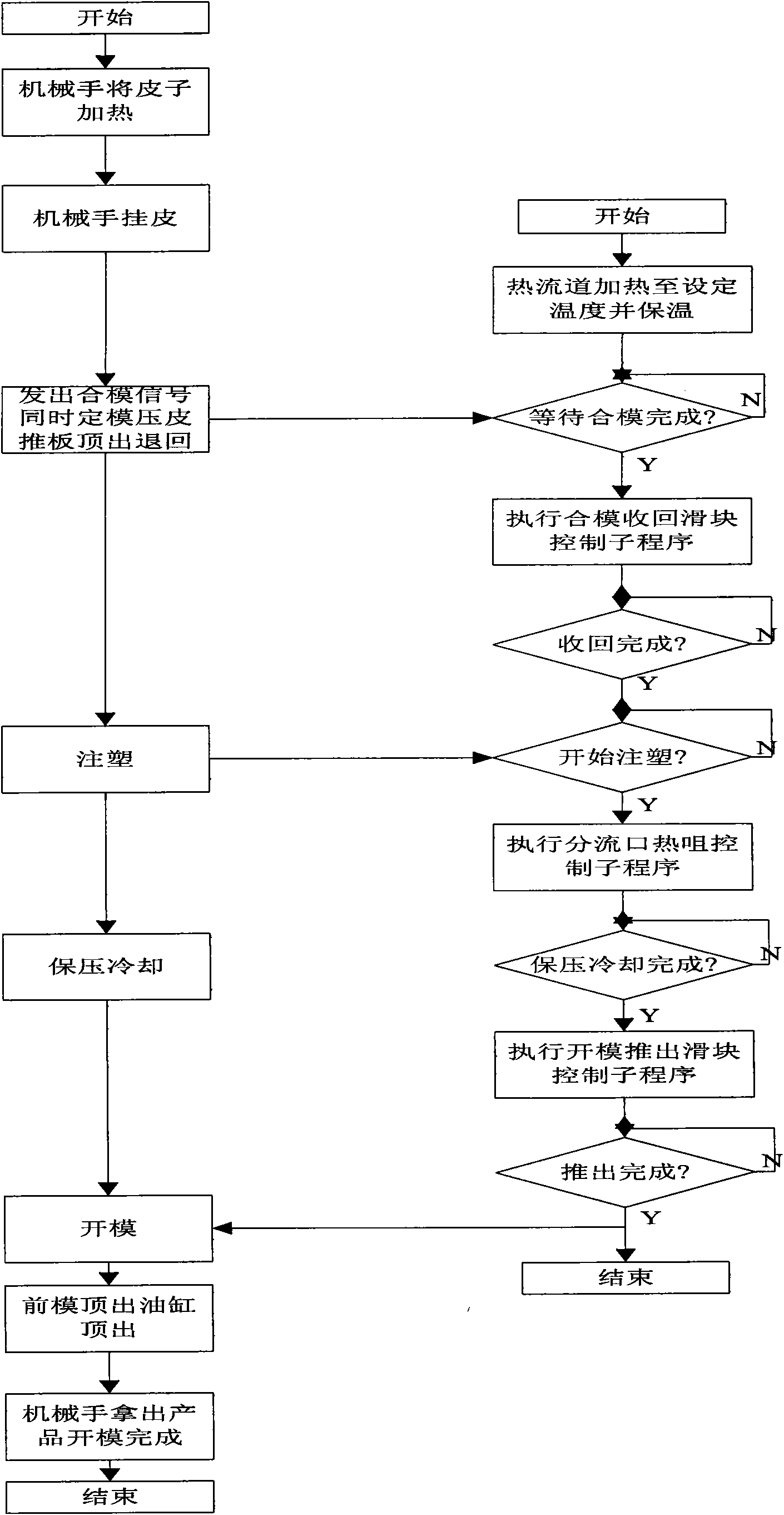

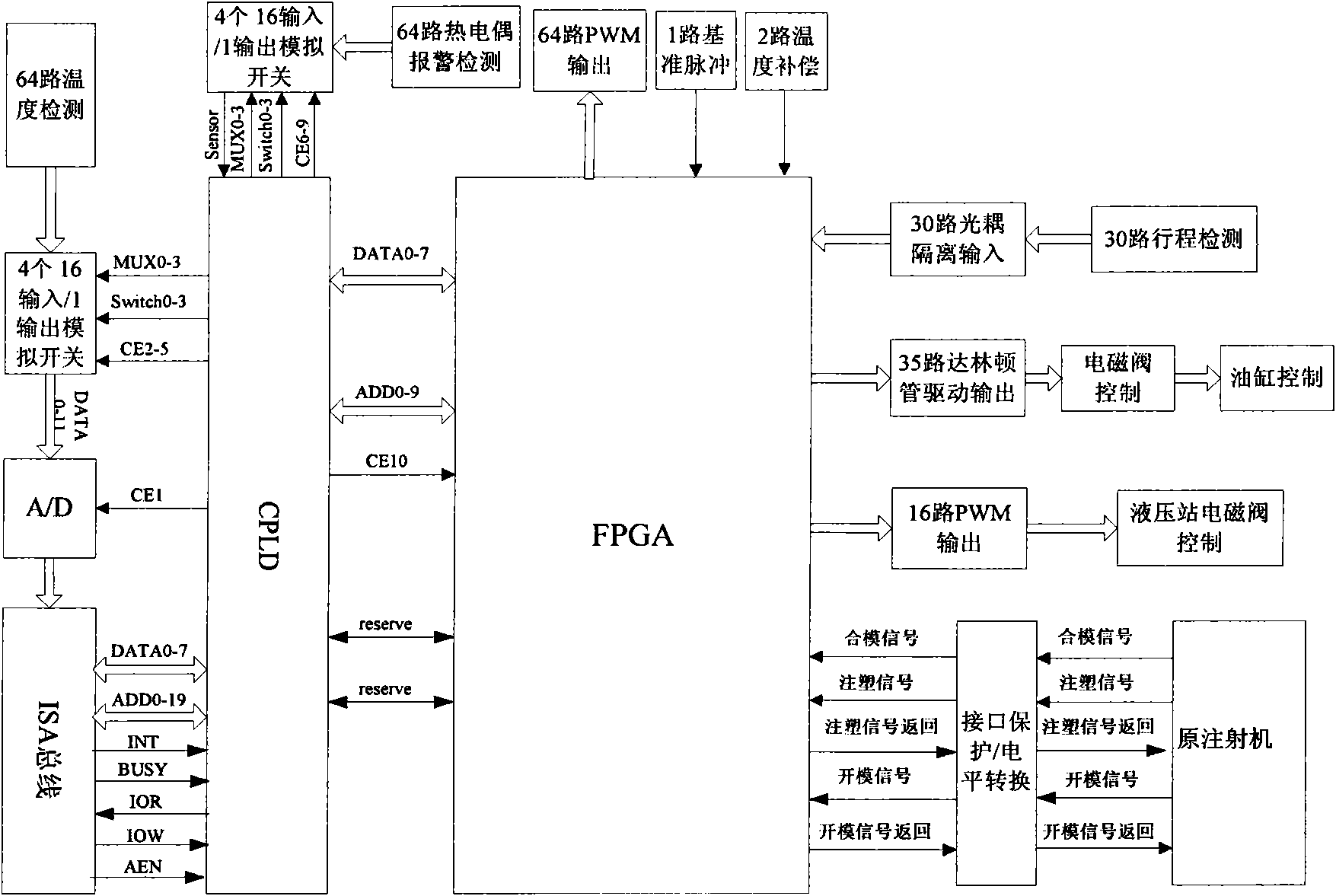

[0038] Such as Figure 1A Shown is a block diagram of the overall structure of the controller module of the preferred embodiment of the present invention. The injection machine control module includes three parts: display unit, control unit and interface unit. The display unit includes a 17-inch LCD monitor and a liquid crystal touch screen. The control unit is divided into two parts: the upper computer control unit and the lower computer control unit. The control core of the upper computer control unit is an industrial computer with a PC104 bus interface. The core of the control unit is FPGA, which is mainly used for temperature detection and control, and accepts the instructions of the host computer to realize the stroke and the action control of the solenoid valve of the oil cylinder. The interface unit mainly includes five modules: temperature detection and control module, stroke detection module, cylinder solenoid valve action control module, communication module with in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com