Joggling ceramic tile and ceramic tile joggling strip

A ceramic tile and tenon joint technology is applied in the field of ceramic tiles and tile paving accessories to achieve the effects of reducing load, saving resources, and being easy to process and implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

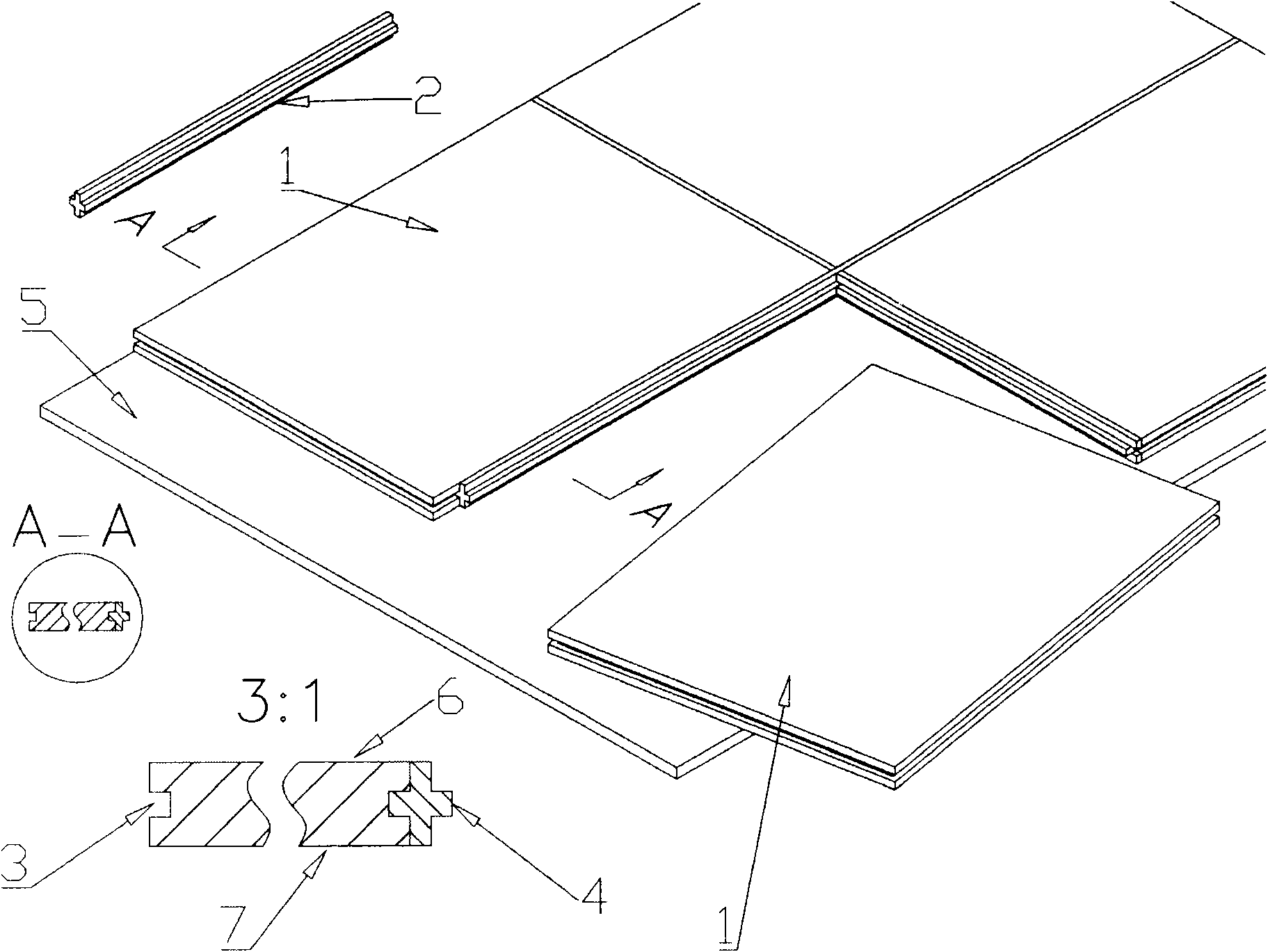

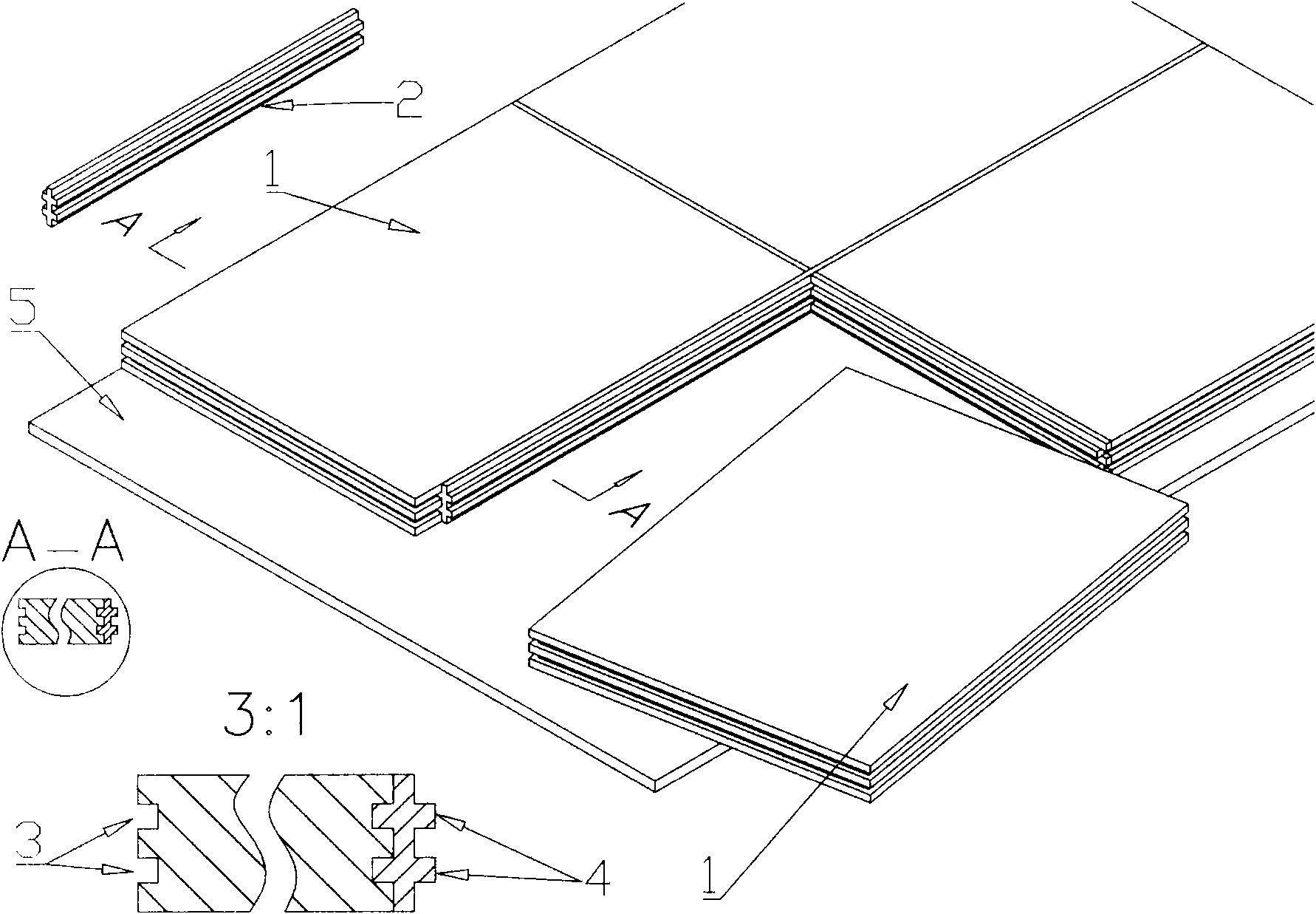

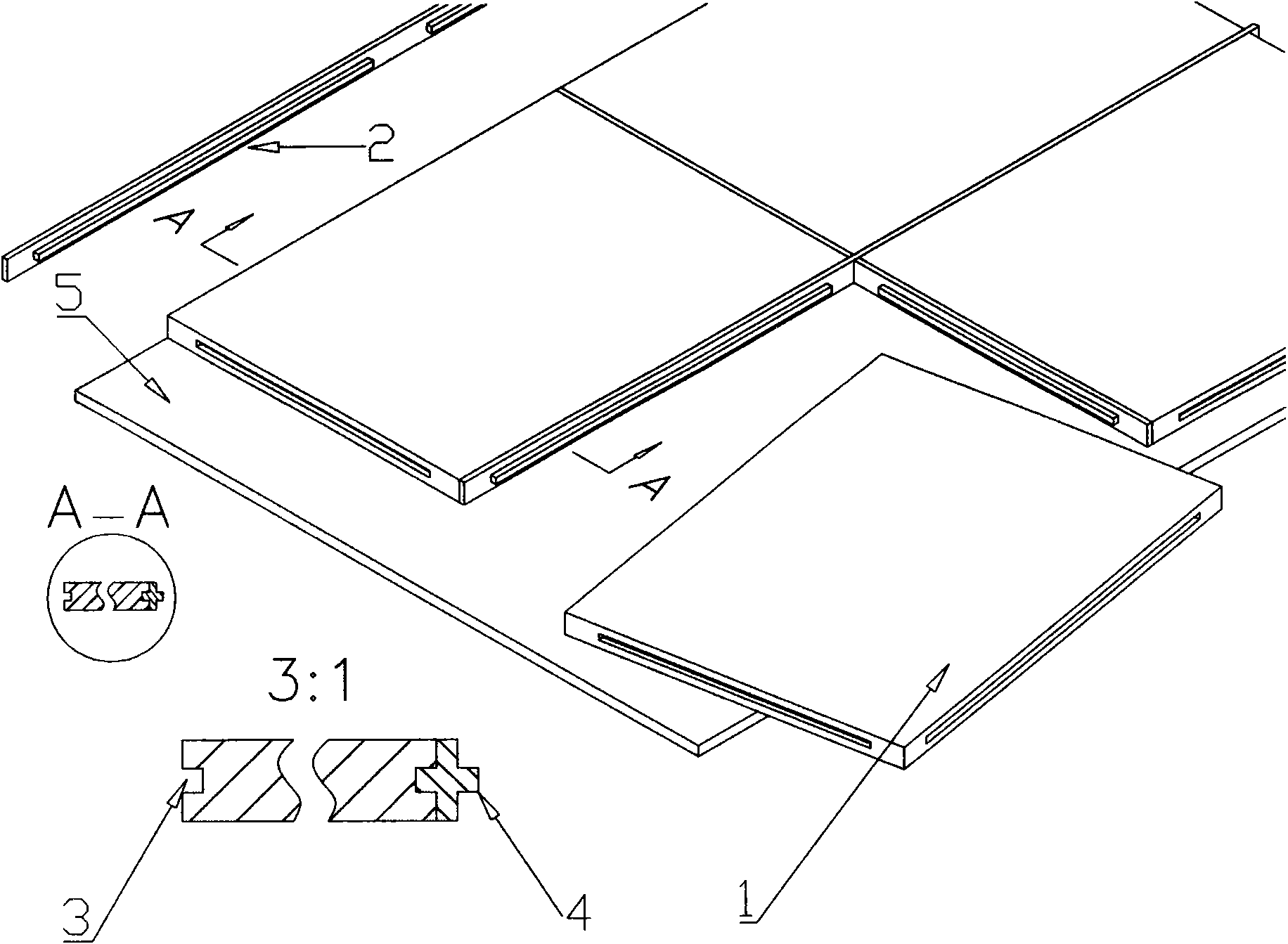

[0018] Tenon 4 or tenon and groove 3 are arranged on the four sides of tenon joint tile 1 in the present invention except the front 6 and the back 7 of the tile, and tenon 4 or tenon and groove 3 are arranged on the tenon joint bar 2 of the tile. The tenon-joint tiles 1 can be paved by tenon-joint with the tenon-joint tiles 2, the tile tenon-joint strips 2 play the role of fixing the tenon-joint tiles 1, and the tile tenon-joint strips 2 act as a buffer to prevent the tenon-joint tiles 1 from cracking. Tenon 4 or tenon and groove 3 can be obtained by grinding the four sides of the fired tiles, or can be molded on the bricks before firing the tiles and then fired into Tent joint tiles 1 finished product. Mortise and tenon tiles 1 can be vitrified tiles, glazed tiles, antique bricks, and tenon 4 and tenon and groove 3 can be processed on natural stone to pave with tile tenon and tenon strip 2. The tenon 4 or the tenon groove 3 on the two sides of the tile mortise strip 2, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com