System and method for use in a combined cycle or rankine cycle power plant using an air-cooled steam condenser

A technology for power equipment and condensers, applied in steam/steam condensers, mechanical equipment, steam engine devices, etc., can solve problems such as performance loss of power equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

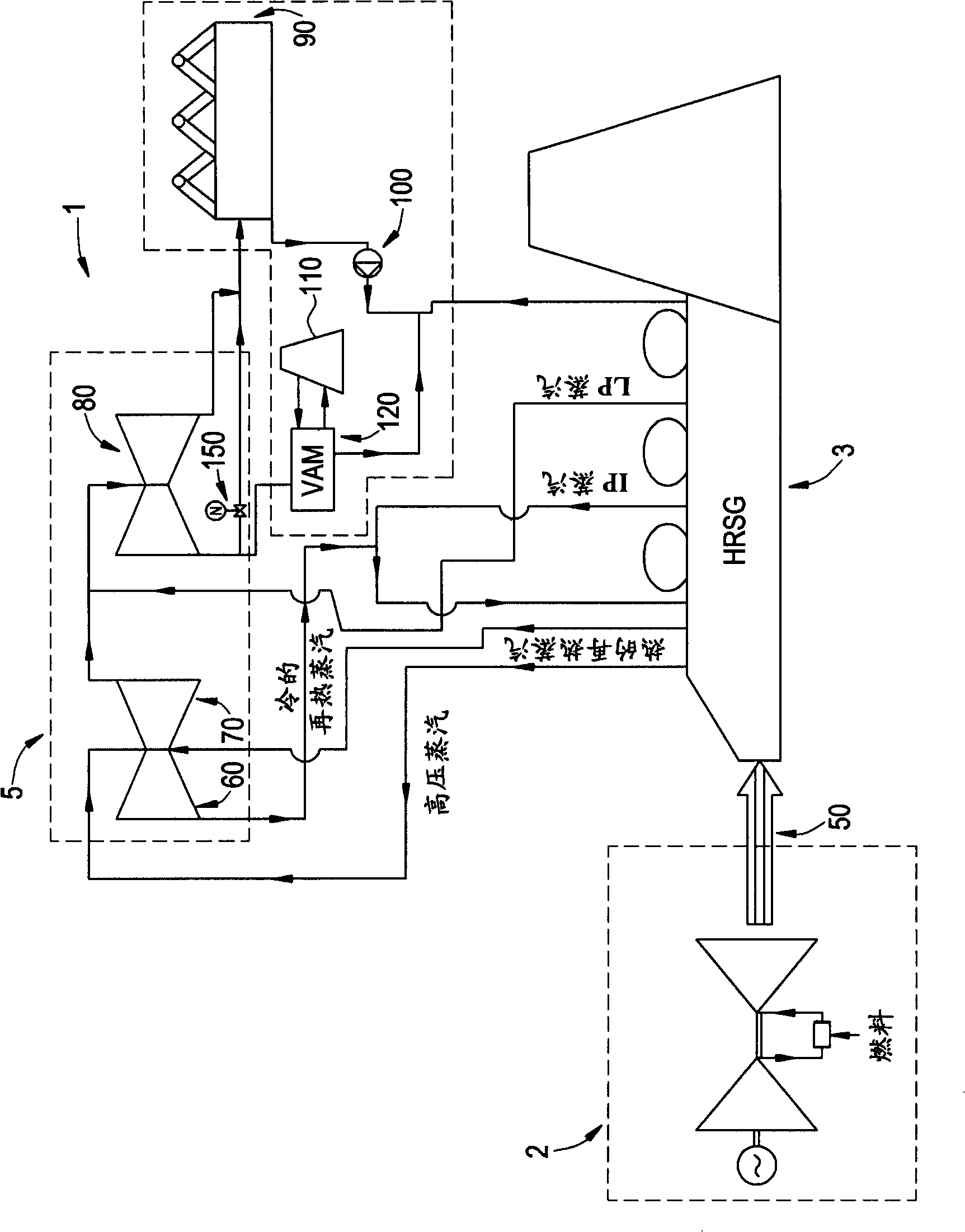

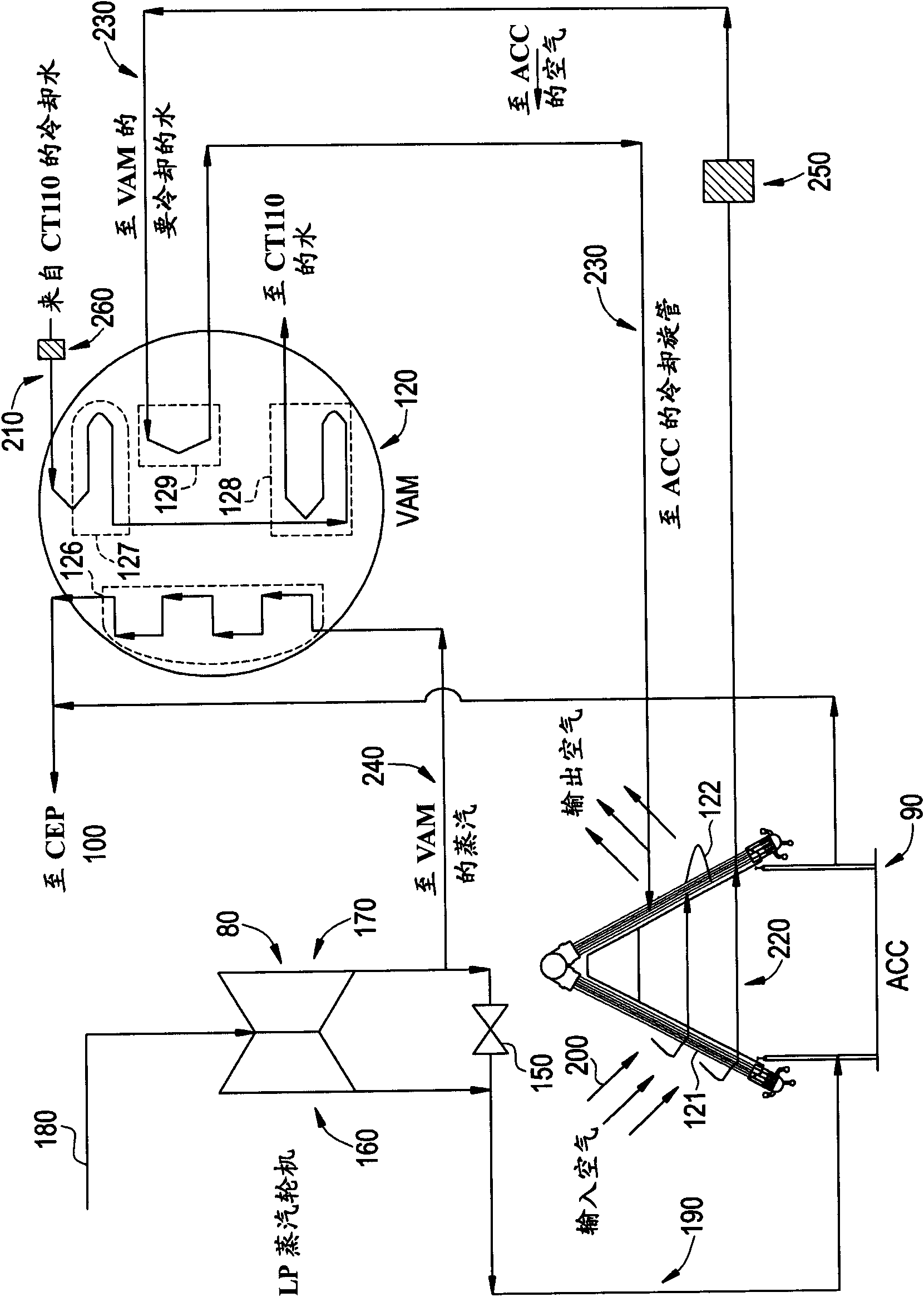

[0013] refer to figure 1 and 2 , provides a system 1 for a power plant, such as a combined cycle or Rankine cycle power plant. This power plant includes a steam source, such as a gas turbine 2, which generates heat 50 during operation, a heat recovery steam generator (HRSG) 3, coupled to the gas turbine 2, a cooling tower 110, a steam turbine 5, such as a high pressure steam turbine (HPST )60, intermediate pressure steam turbine (IPST)70 and low pressure steam turbine (LPST)80. The HRSG 3 generates steam by the heat generated by the gas turbine 2 and includes heat exchangers such as high-temperature heaters, evaporators, and preheaters, which are arranged in the HRSG along the axis, through which part of the generated steam is diverted to the HPST 60, IPST70 and LPST80. Via the diverted steam, the HPST60, IPST70 and LPST80 generate energy, such as electricity, and output a used steam supply. Operation of the system 1 involves the use of at least the spent steam supply of L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com