Piston-type hydro-pneumatic buffer

A liquid-gas buffer and piston-type technology, applied in the direction of gas-liquid shock absorbers, etc., can solve the problems of short maintenance period, high energy consumption, poor sealing performance, etc., reduce the difficulty of sealing and improve the ability to block oil leakage , Play the effect of working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

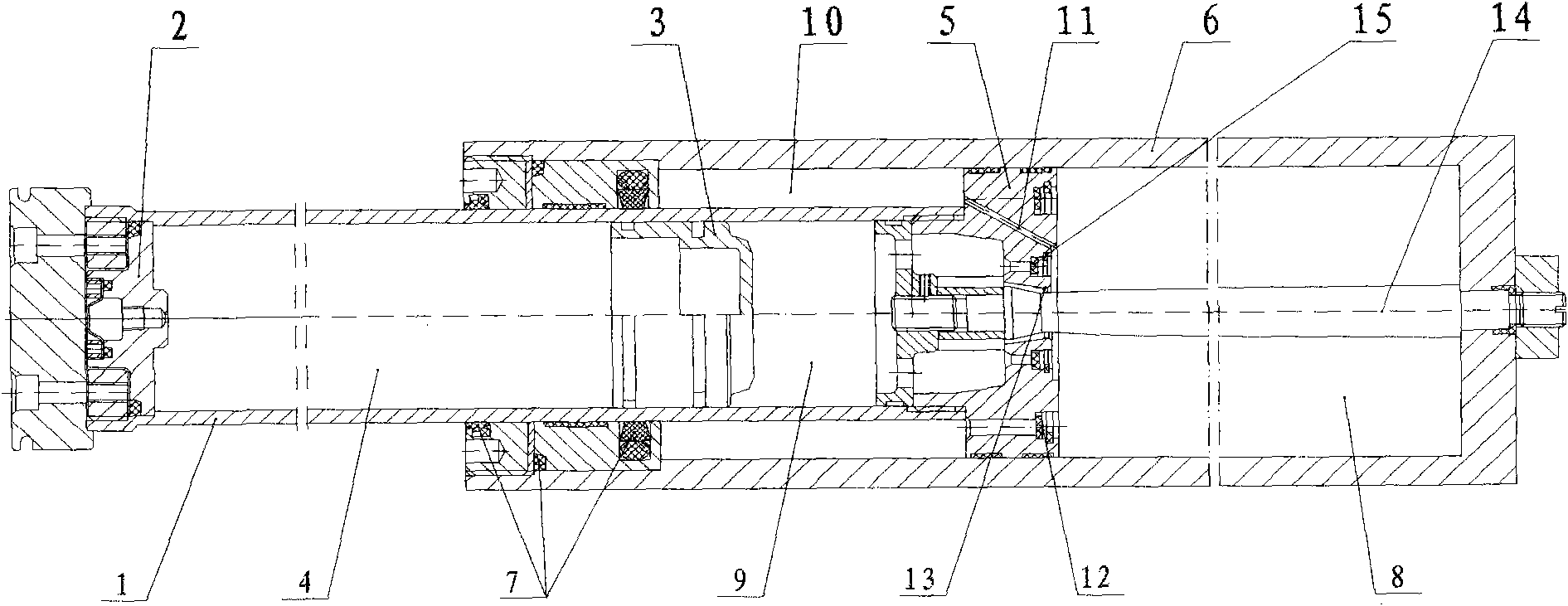

[0028] The embodiments will be described in detail below in conjunction with the accompanying drawings, through which the concept of the present invention can be more clearly understood.

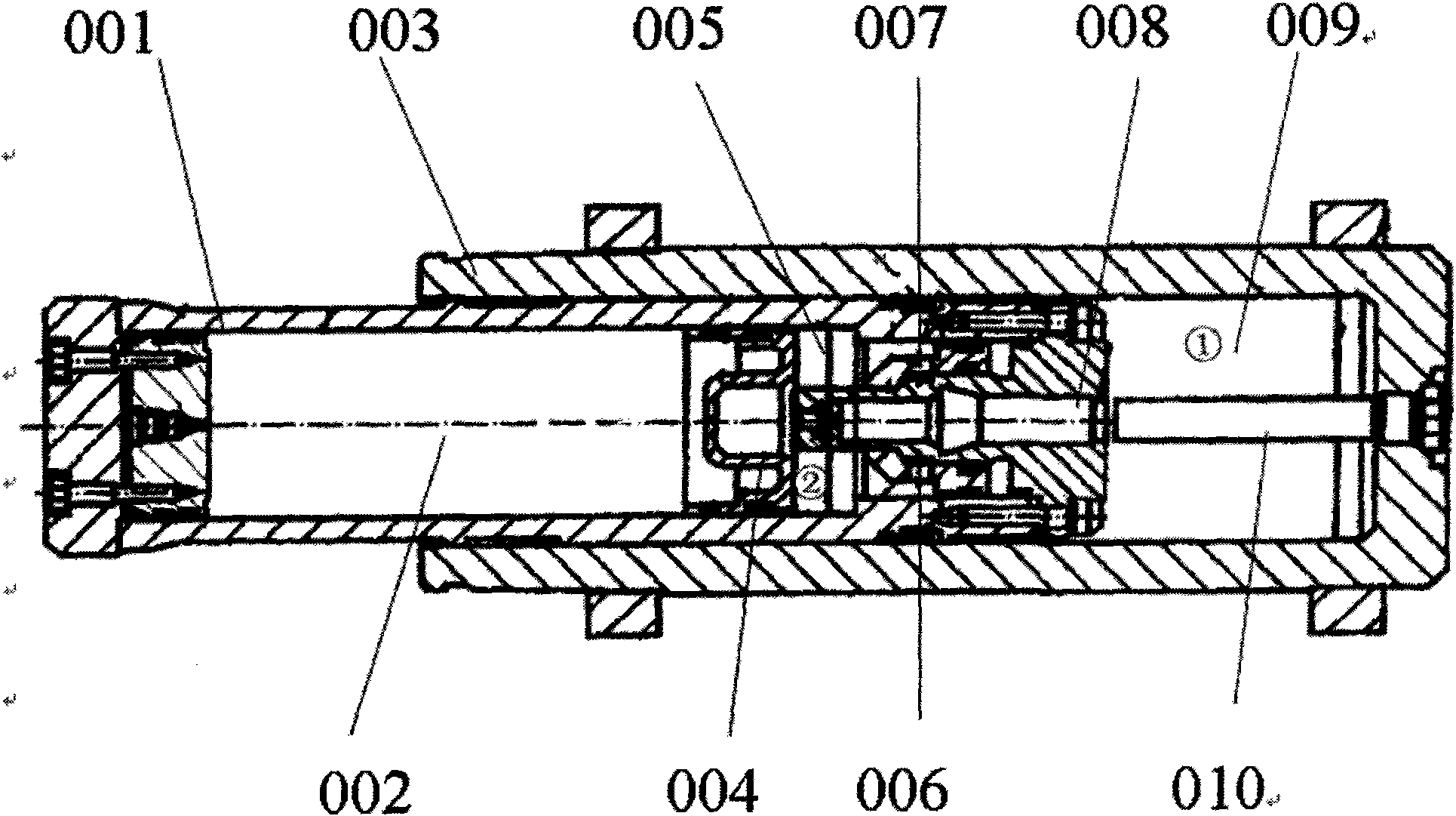

[0029] figure 2 It is a structural schematic diagram of an embodiment of the present invention.

[0030] In the piston-type liquid-gas buffer of this embodiment, 1 is a hollow piston rod, and an air-tight device 2 is provided at one end of the piston rod, and 3 is a floating piston arranged in the piston rod, which can slide along the inner wall of the piston rod. Between the piston and the air-tight device 2 is an air chamber 4, which is filled with compressed gas. The suitable gas used in this example is nitrogen, and the pressure of nitrogen in this example is 0.5-1 MPa; 5 is the other end of the piston rod The piston provided at the place, the second oil chamber 9 is formed between the piston 5 and the floating piston in the piston rod, and the piston 5 has an oil cylinder 6 which is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com