An Electromagnetic Ultrasound Online Monitoring System Based on Pulse Compression Method

An electromagnetic ultrasonic and pulse compression technology, which is used in transmission systems, analysis of solids using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves. , monitoring equipment body safety hazards and other issues, to achieve the effect of low-voltage networking, improving equipment security, and enhancing monitoring coverage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

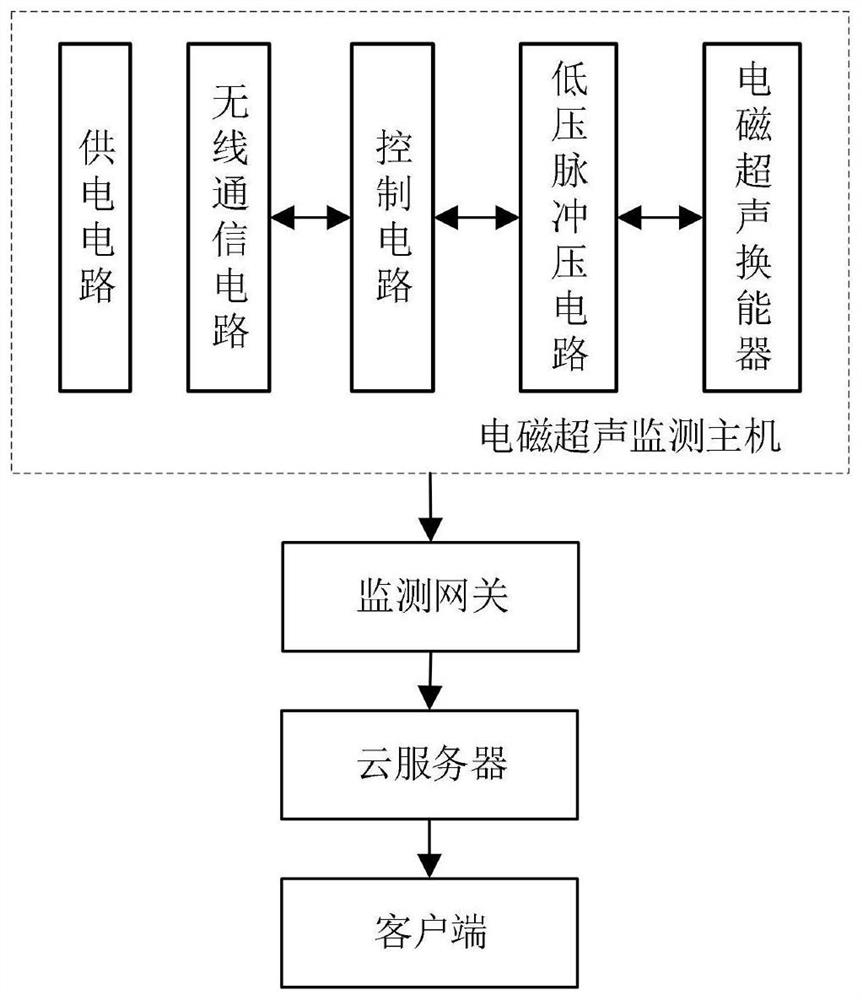

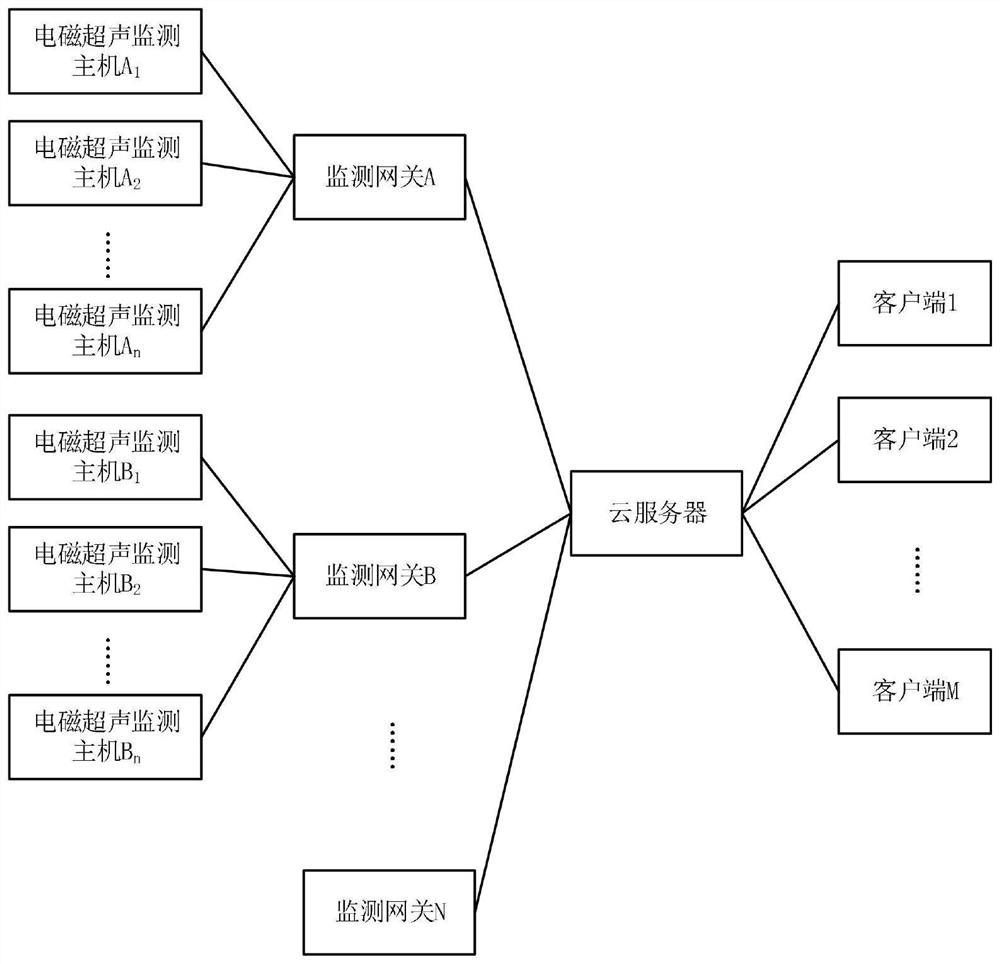

[0029] Combine below Figures 1 to 7 Describe this embodiment, an electromagnetic ultrasonic online monitoring system based on the pulse compression method, including an electromagnetic ultrasonic monitoring host 3-1, a monitoring network, a cloud server, and a client, the electromagnetic ultrasonic monitoring host 3-1 uses pulse compression to The workpiece 3-2 is monitored, the electromagnetic ultrasonic monitoring host 3-1 is connected to the monitoring network through a wireless network, the cloud server and the monitoring network are connected through the Internet, and the client and the cloud server are connected through the Internet; according to the To measure the size of the workpiece 3-2, the electromagnetic ultrasonic monitoring host 3-1 is detachably installed on the measured workpiece 3-2 through strong permanent magnet adsorption and binding with cable ties 3-3, and the control circuit controls the low-voltage pulse compression The circuit excites the low-voltage...

specific Embodiment approach 2

[0031] Combine below Figures 1 to 7 Describe this embodiment, this embodiment will further explain Embodiment 1, the electromagnetic ultrasonic monitoring host 3-1 has a low power consumption sleep function, and the electromagnetic ultrasonic monitoring host 3-1 can be detachably installed on the workpiece 3-2 to be measured; The wireless communication circuit on the electromagnetic ultrasonic monitoring host 3-1 adopts Lora circuit, through the sleep control of its main chip, it can realize the low power consumption and sleep wake-up of the electromagnetic ultrasonic monitoring host 3-1.

specific Embodiment approach 3

[0033] Combine below Figures 1 to 7 Describe this embodiment mode. This embodiment mode will further explain Embodiment 2. The electromagnetic ultrasonic monitoring host 3-1 includes a housing, a power supply circuit, a wireless communication circuit, a control circuit, a low-voltage pulse compression circuit, and an electromagnetic ultrasonic transducer. There is a power supply circuit inside, the power supply circuit supplies power to the wireless communication circuit, the control circuit and the low-voltage pulse compression circuit, the communication signal input and output terminals of the wireless communication circuit are connected to the control circuit, and the control signal input and output terminals of the control circuit are connected to the low-voltage The pulse circuit is connected, and the power signal output end and the weak signal receiving end of the low-voltage pulse compression circuit are connected with the electromagnetic ultrasonic transducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com