Manual drive control valve and wood splitting machine provided with same

A hand-operated and controlled valve technology, applied in valve operation/release devices, valve devices, wood splitting devices, etc., can solve the problems of complex structure and many parts, and achieve high operational reliability, high efficiency and low technical requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

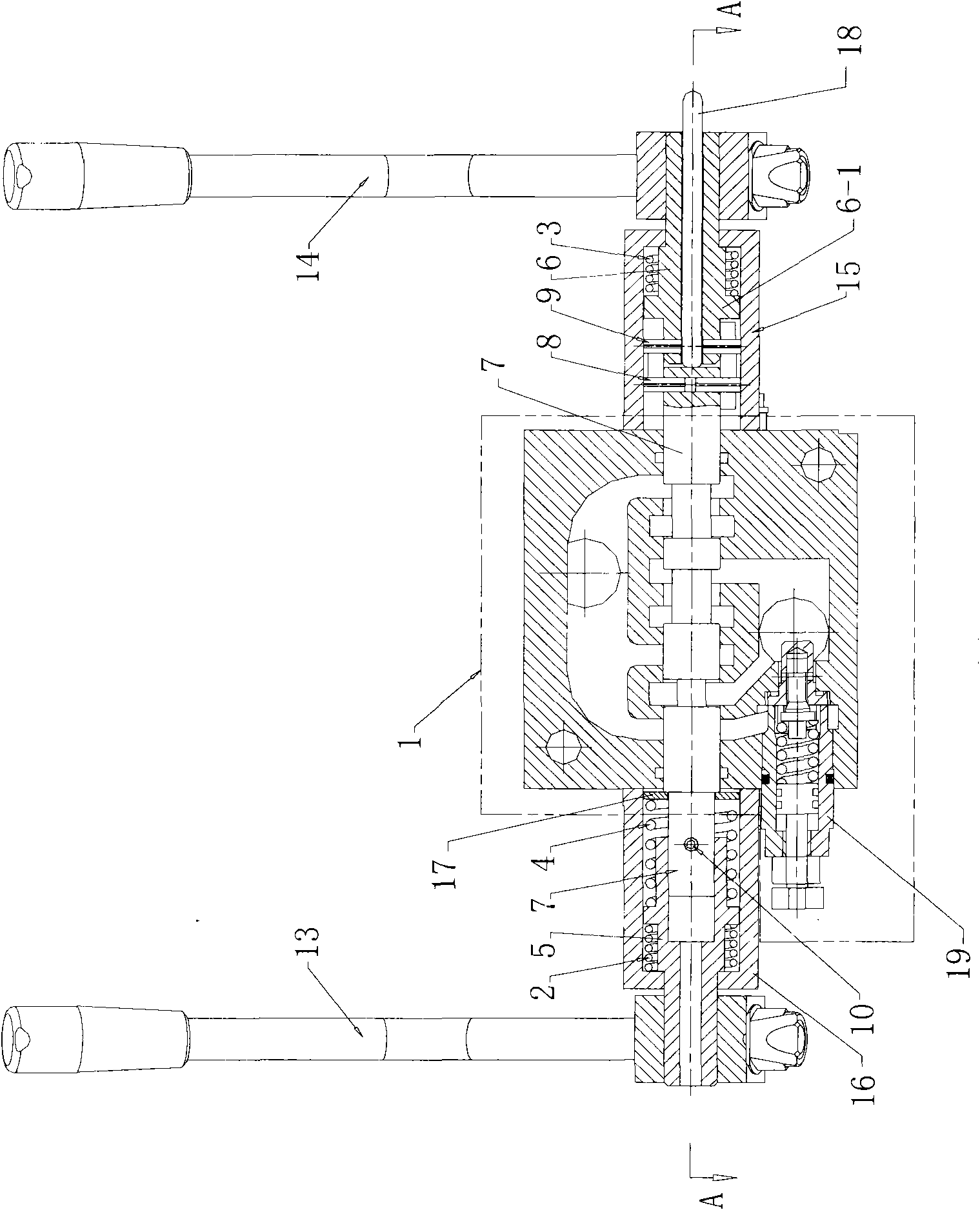

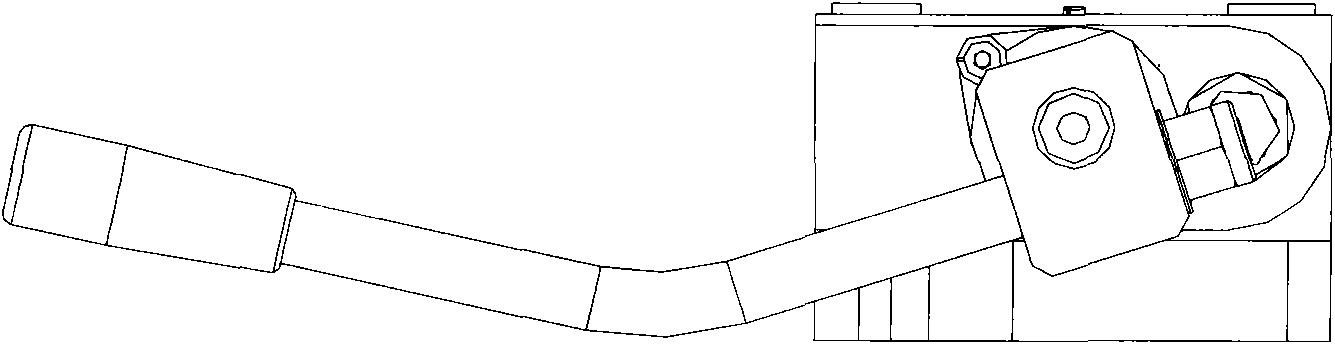

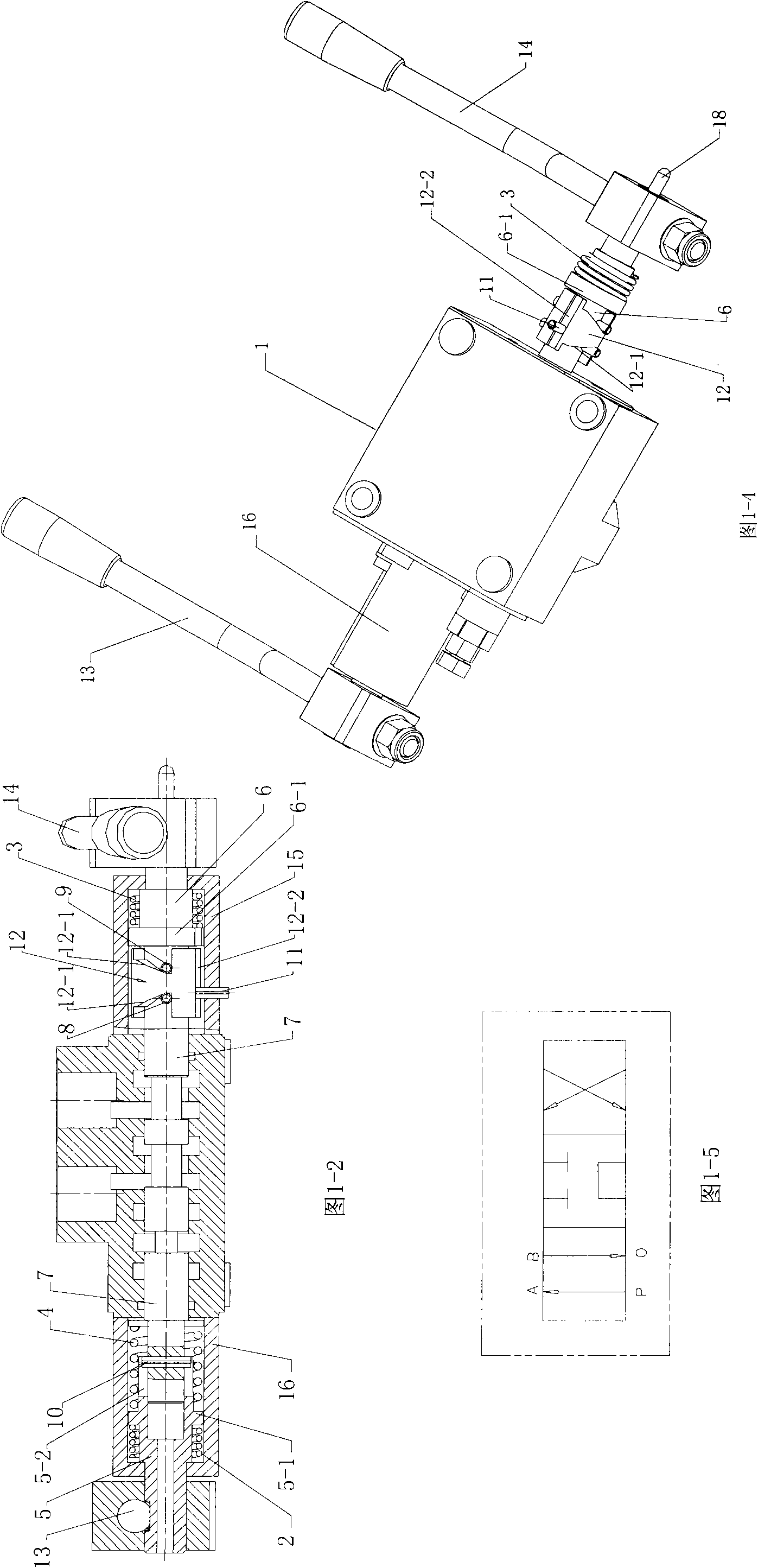

[0037] see Picture 1-1 , Figure 1-2 , Figure 1-3 , Figure 1-4 and Figure 1-5 , manual control valve assembly --- internal structure: Picture 1-1 The assembly relationship of the main parts shown in the dotted line is the main valve body 1 of the valve. The valve is a three-position four-way reversing valve. Its hydraulic principle is as follows: Figure 1-5 shown.

[0038] One side of the main valve body 1 and the handle 14 is provided with a right-handed sleeve 6, a cam 12, and a cover 15. The right-handed sleeve 6 is equipped with a torsion spring 3, and the handle 14 is connected with the right-handed sleeve 6. , the inner end of the right-handed sleeve 6 is equipped with elastic pins 8 and 9 adjacent to the valve core.

[0039] The cam 12 is sleeved on the right-handed sleeve 6, and the cam 12 has a symmetrical cam surface 12-1. The cam surface 12-1 can be a spiral surface, and of course other forms of surfaces can also be used. The elastic pin 9 of the right-ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com