Composite plate assembly

A technology of composite panels and assemblies, applied in the direction of sheet/board, thin panel connection, building components, etc., can solve the problems of long construction time, inconvenience, and program delay in assembly operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

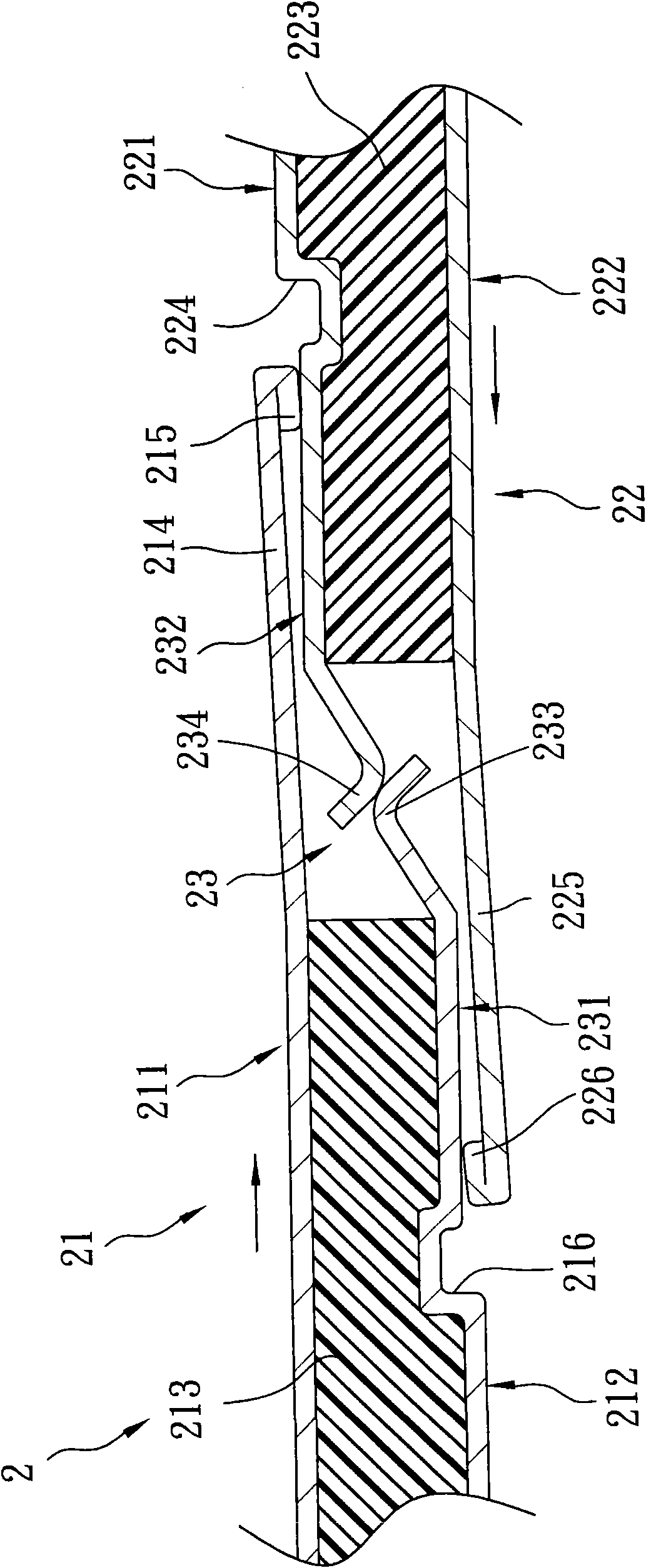

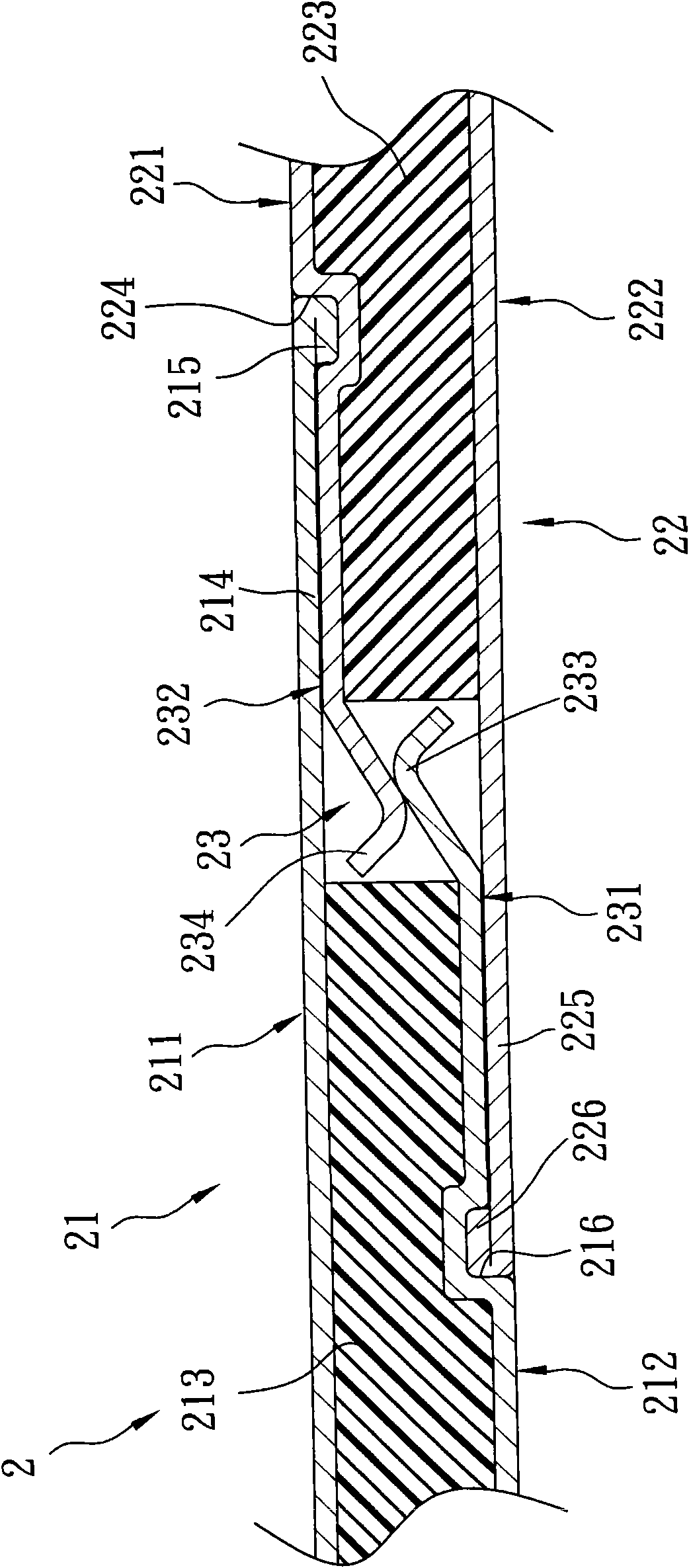

[0015] Such as figure 2 and image 3 As shown, a first preferred embodiment of the composite board assembly 2 of the present invention includes a first composite board 21, a composite board combined with the first composite board 21 through means of gluing and fastening. The second composite board 22 and a buckle unit 23 .

[0016] The first composite sheet 21 has an upper metal layer 211 , a lower metal layer 212 spaced apart from the upper metal layer 211 , and a non-metallic core layer 213 sandwiched between the upper and lower metal layers 211 , 212 . The upper metal layer 211 has a right side protruding from the non-metallic core layer 213 (corresponding to figure 2 direction, hereinafter the same), and an overlapping layer portion 214 extending from a right end of the overlapping layer portion 214 toward a direction away from the non-metallic core lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com