Digital application of protective soldermask to printed circuit boards

A technology of printed circuit board and solder mask, which is applied in the direction of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve problems such as affecting steps, and achieve the effect of eliminating time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

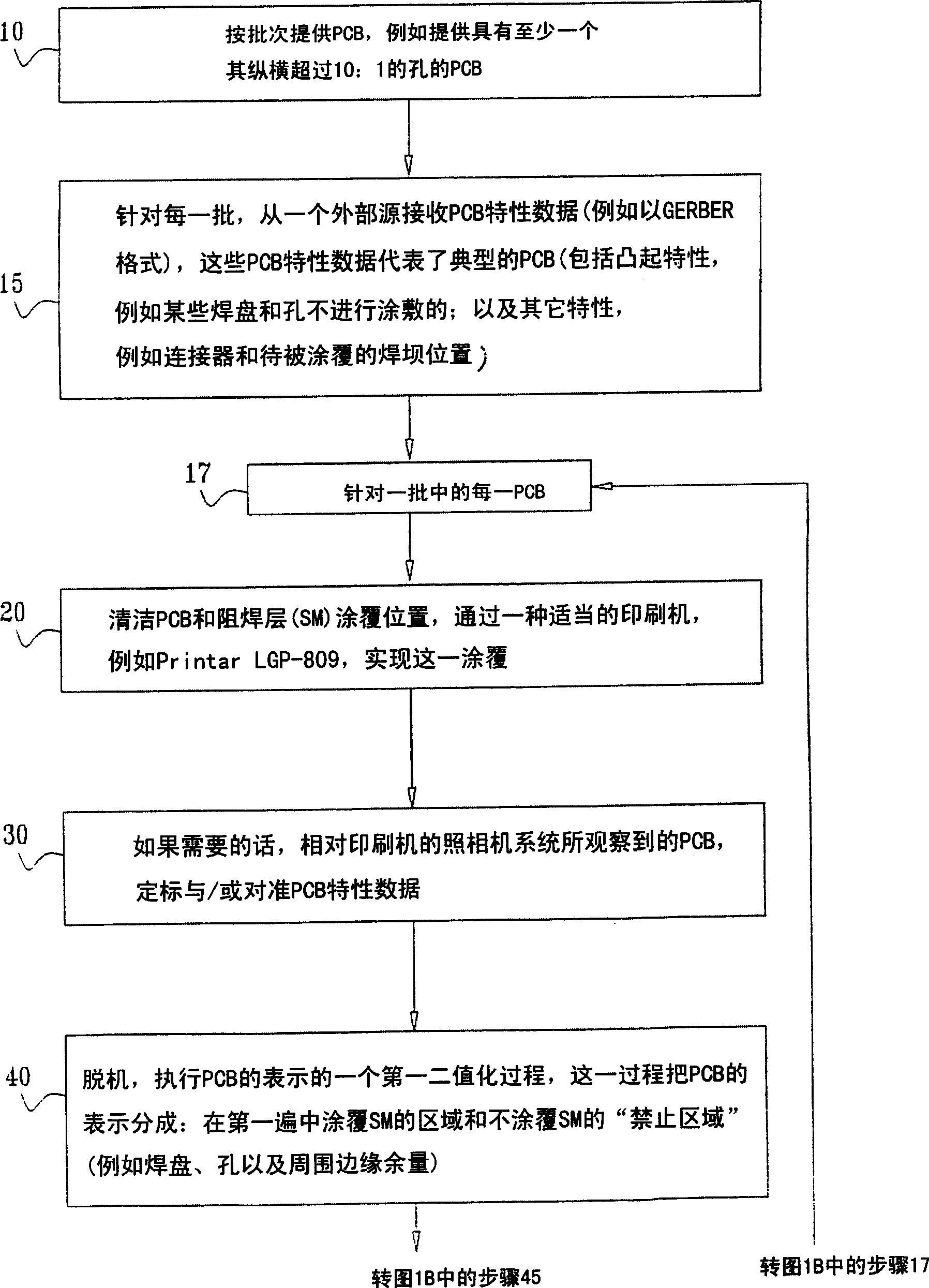

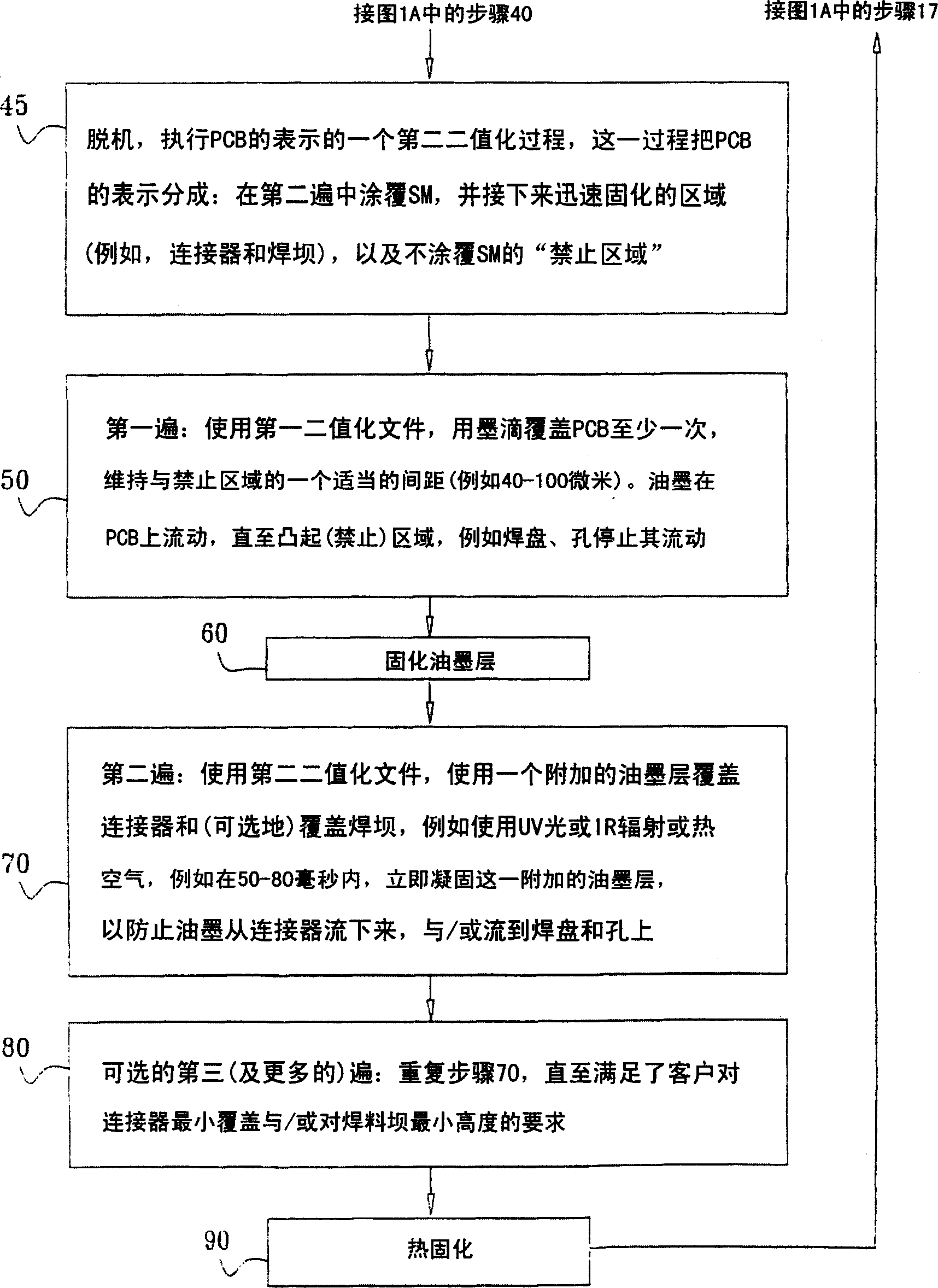

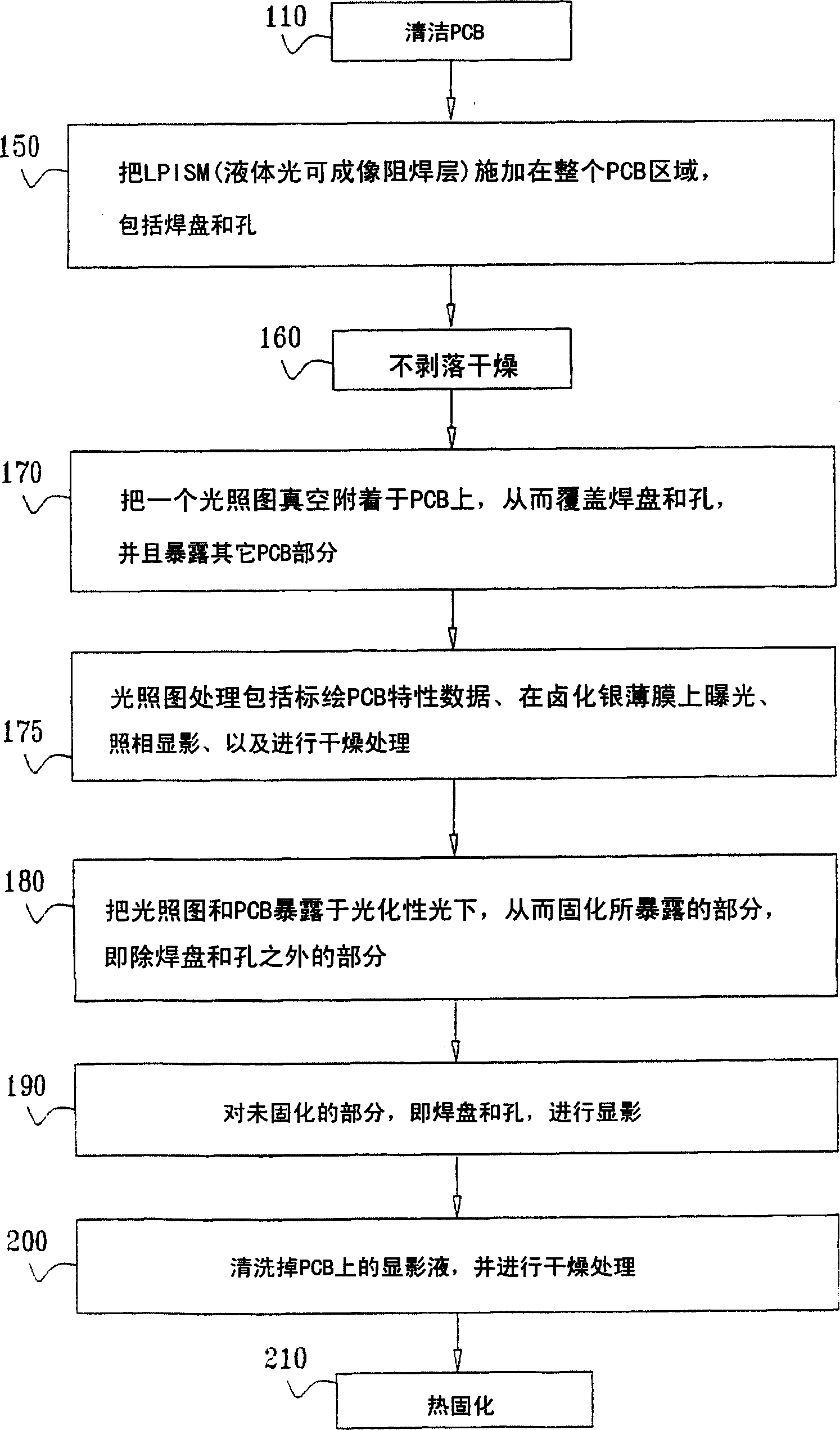

[0051] now refer to Figure 1A-1B . Figure 1A-1B Together, this forms a simplified flowchart of a method for digitally applying protective solder mask to a printed circuit board, constructed and operative in accordance with a preferred embodiment of the present invention.

[0052] Preferably, a digital solder resist drop placement system similar to that illustrated and described in published PCT application PCT / IL01 / 00596 (WO 02 / 01929) is used to achieve Figure 1A-1B Methods.

[0053] In step 50, drops of digital solder resist, also referred to herein as "ink drops", are placed over the entire area of the circuit board except for the keep-out areas. These ink droplets flood the exposed parts of the printed circuit board. The copper layer has been etched away from these exposed parts, also referred to herein as the "lamination areas" of the printed circuit board. During the pouring process, the pad stops the flow of liquid solder mask. This step brings the solder mask clo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com