3D detection method for rail surface defects

A technology for three-dimensional inspection and rail, which is applied in the direction of optical testing for flaws/defects, etc. It can solve problems such as difficult grayscale image distinction, difficult lighting and image acquisition, and easy occlusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

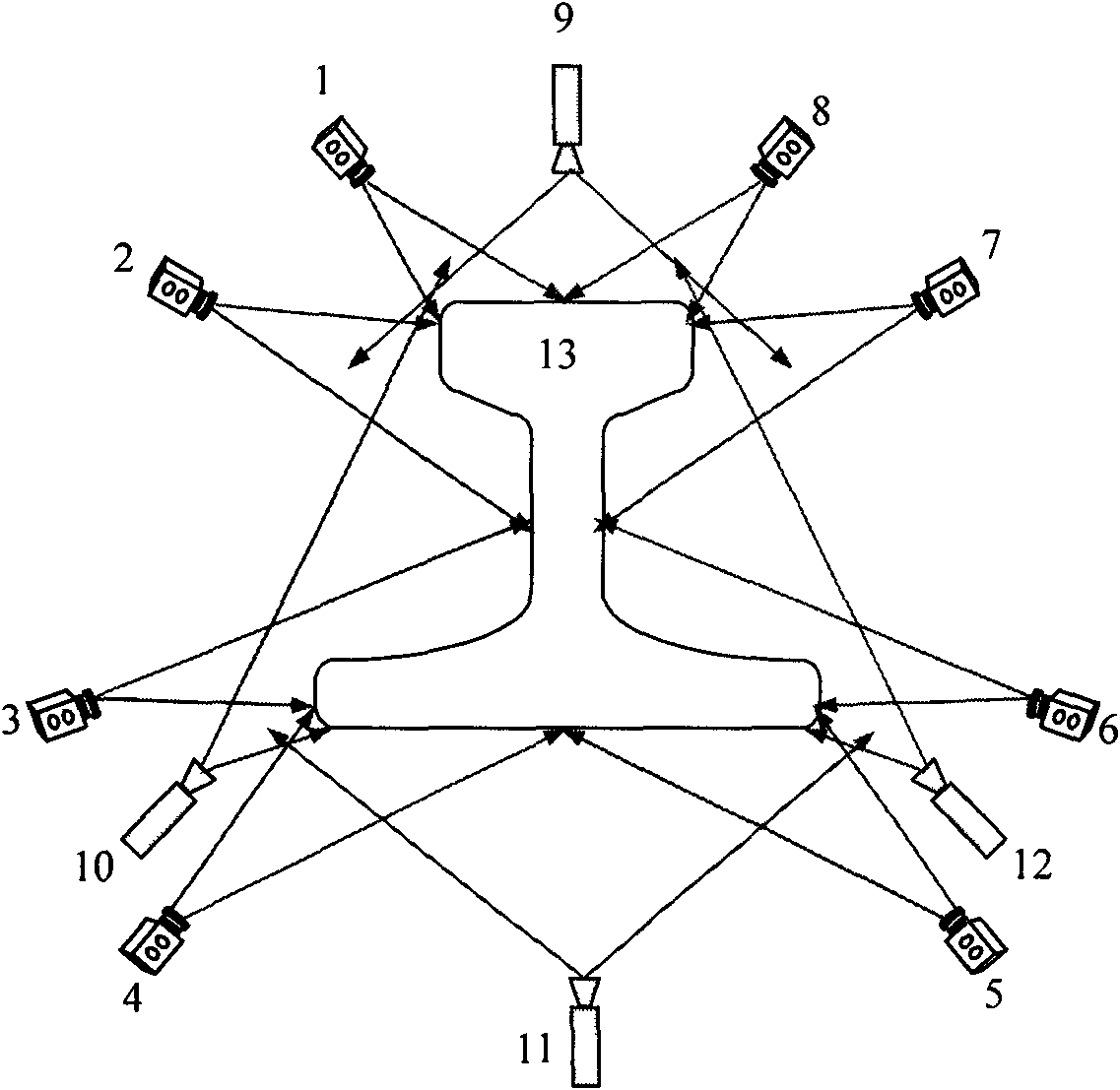

[0015] In order to realize the detection of the entire section of the rail, 8 area array CCD cameras and 4 laser line light sources are used. figure 1 Among them, the laser line light source 9 is placed directly above the top surface of the rail 13, and the emitted laser lines cover the entire top surface and two corners of the top surface; the laser line light source 11 is placed directly below the bottom surface of the rail 13, and the emitted laser lines Cover the entire bottom surface and the two corners of the bottom surface; the laser line light sources 10 and 12 are respectively placed under the two outer sides of the bottom surface of the rail 13, and the emitted laser lines cover the two sides of the rail 13 respectively, the laser line light source 9, the laser line light source 10. The laser lines emitted by the laser line light source 11 and the laser line light source 12 are on the same light plane, perpendicular to the running direction of the rail 13, and the las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com