Gas displacement and dynamic compensation sampling method in headspace analysis

A gas replacement and dynamic compensation technology, applied in the field of headspace analysis, can solve the problems of sample loss and long running time, and achieve the effect of short sampling time, good reproducibility and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

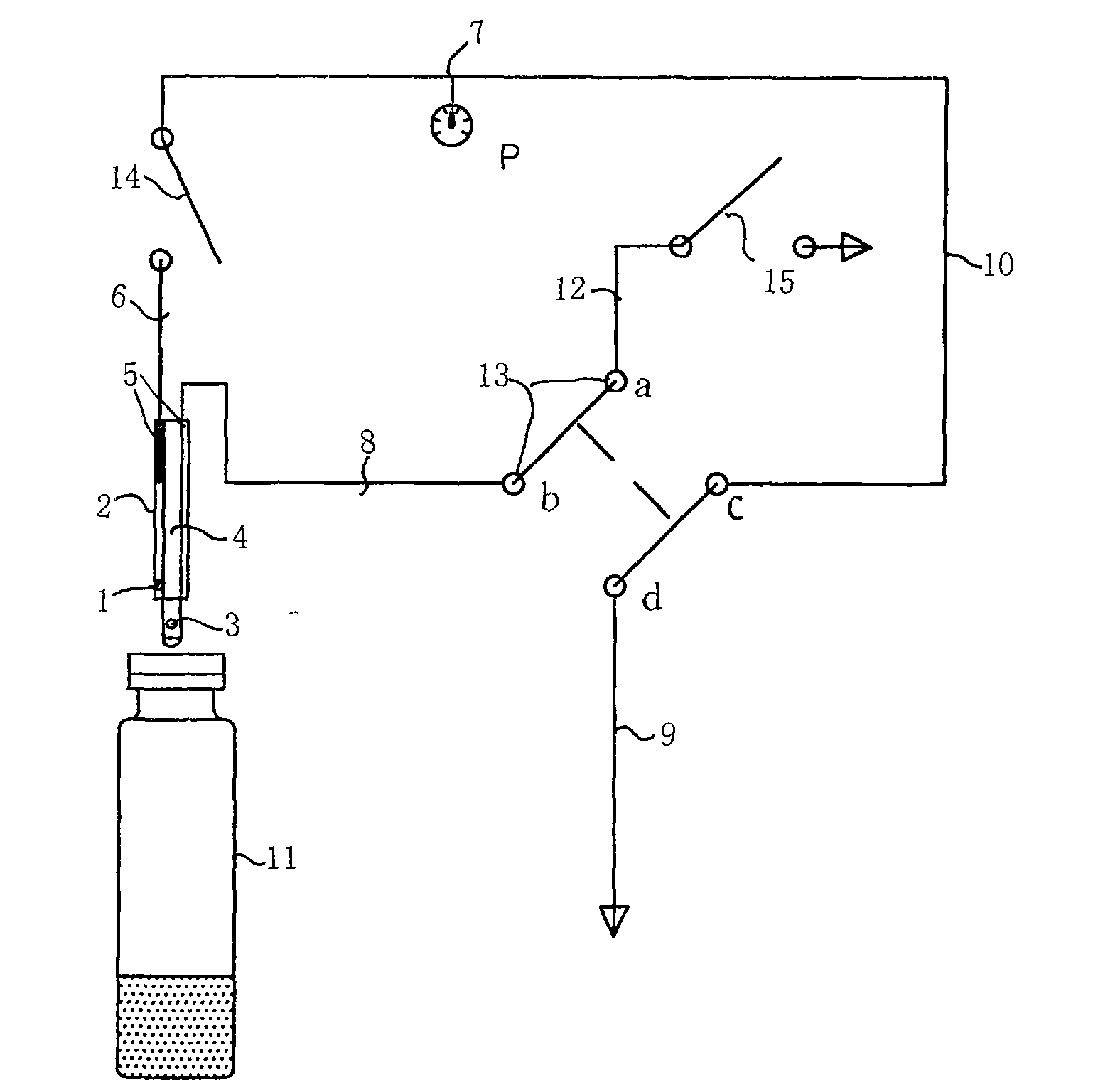

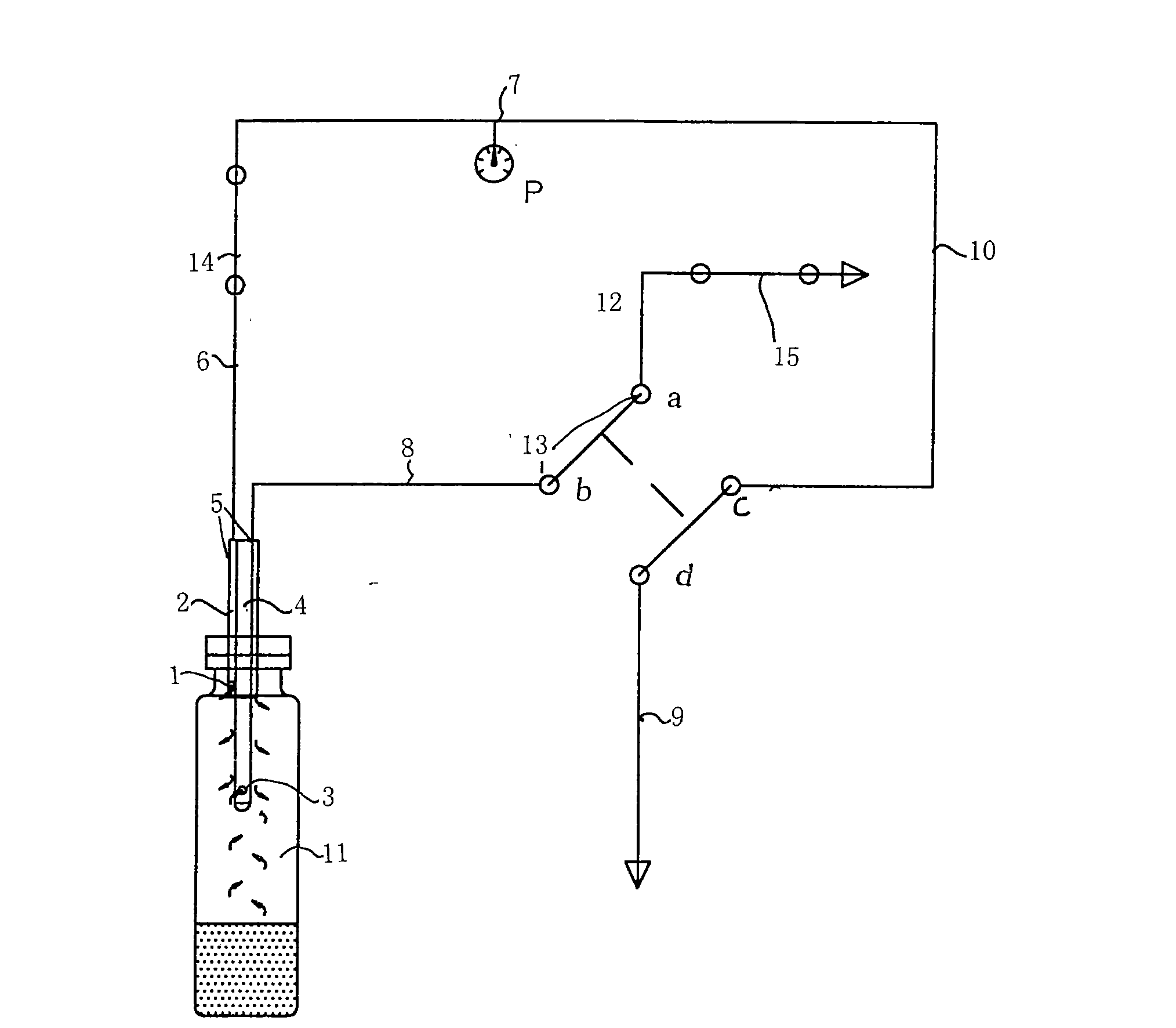

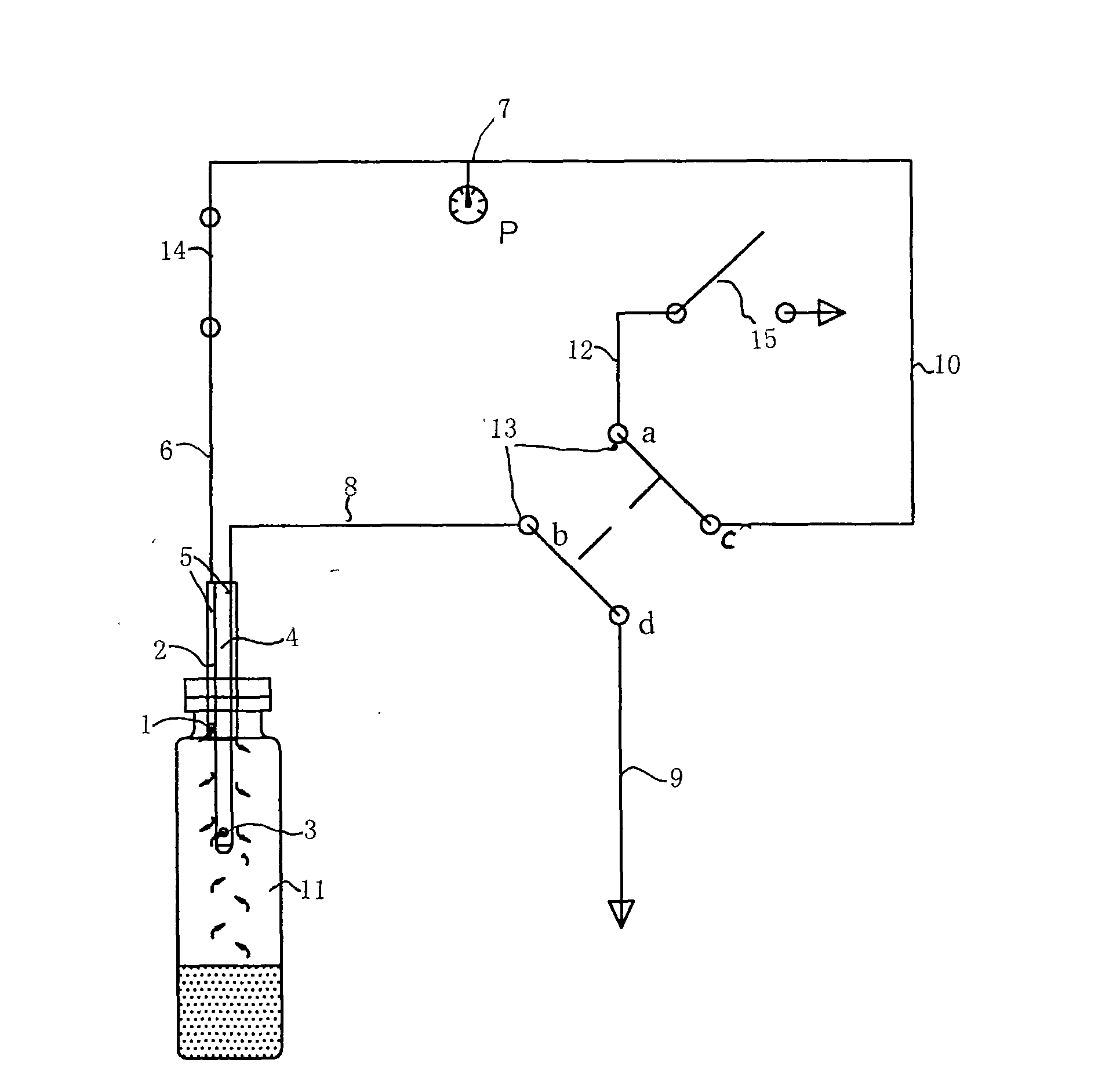

[0024] see figure 1 The gas replacement and dynamic sampling device for headspace analysis in this embodiment includes an outer needle 2 containing an inlet carrier gas hole 1 and a double needle 5 with an inner needle 4 containing an air outlet hole 3 that is passed through the outer needle. The first carrier gas pipeline 6 connected to the carrier gas hole communicates with the carrier gas source 7 . The first end of the inner needle connecting pipe 8 communicates with the air outlet of the inner needle. The first end of the second carrier gas pipeline communicates with the carrier gas source. Install between the second end of the second end of the carrier gas pipeline, the second end of the second carrier gas pipeline 10, the first end of the exhaust pipeline 12, and the delivery pipeline 9 that the first end communicates with the gas chromatograph inlet. There is a switching valve 13 for controlling the connection and disconnection of the inner needle connection pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com