Wide-aperture optical lens for laser

An optical lens and large-aperture technology, applied in the direction of optics, optical components, instruments, etc., to achieve the effect of uniform imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

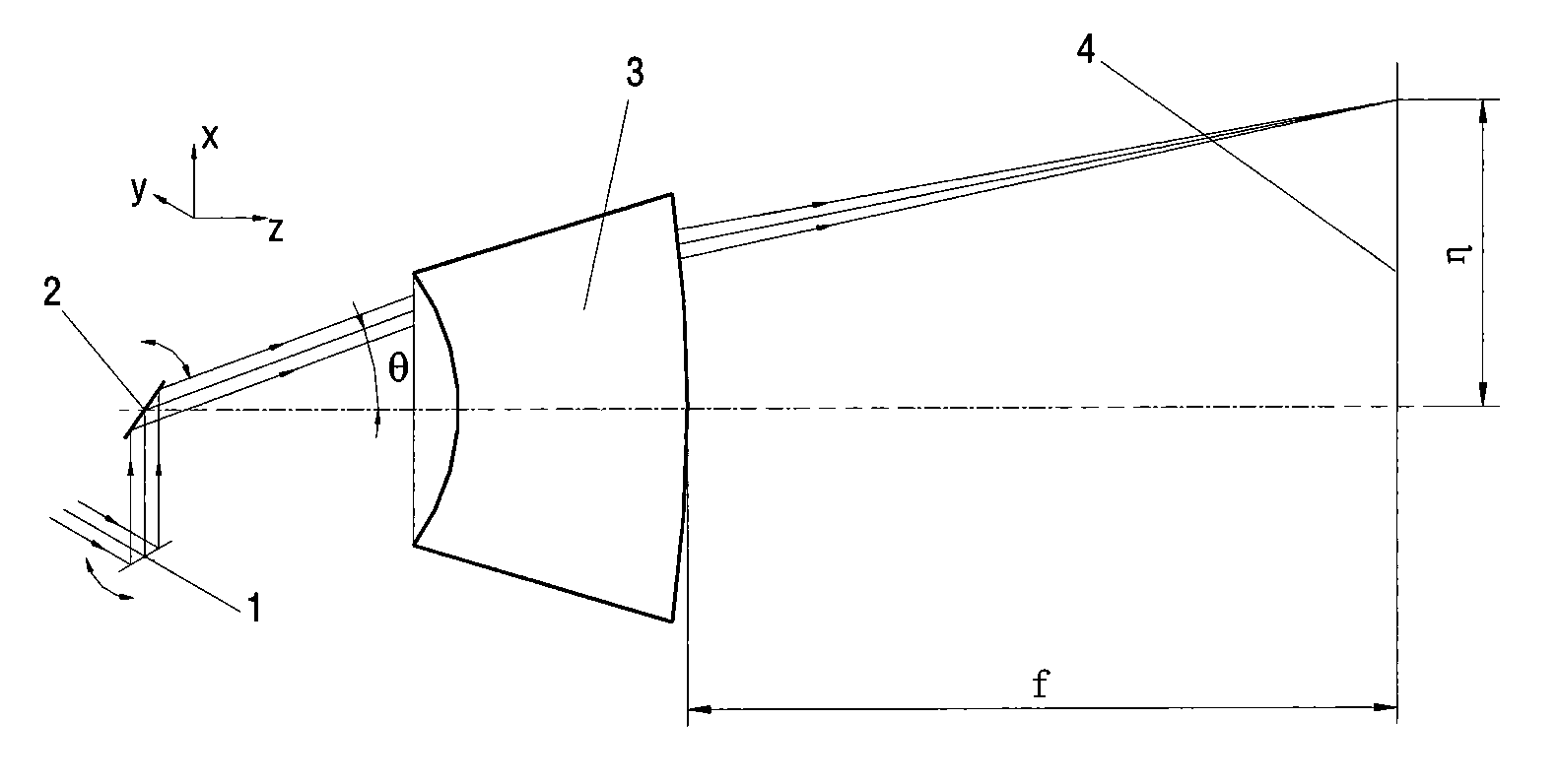

[0025] The present invention applies a large-aperture fθ optical lens for laser application. The main advantage of the lens is that: compared with the general laser application fθ lens of the same focal length, the relative aperture and light diameter of the lens are higher than that of the common laser application fθ lens. 2-3 times larger, the maximum light diameter of the lens can reach 30mm; and it requires a large field of view and a long focal length, which adds great difficulty to the design. The present invention is exactly to solve this difficult problem.

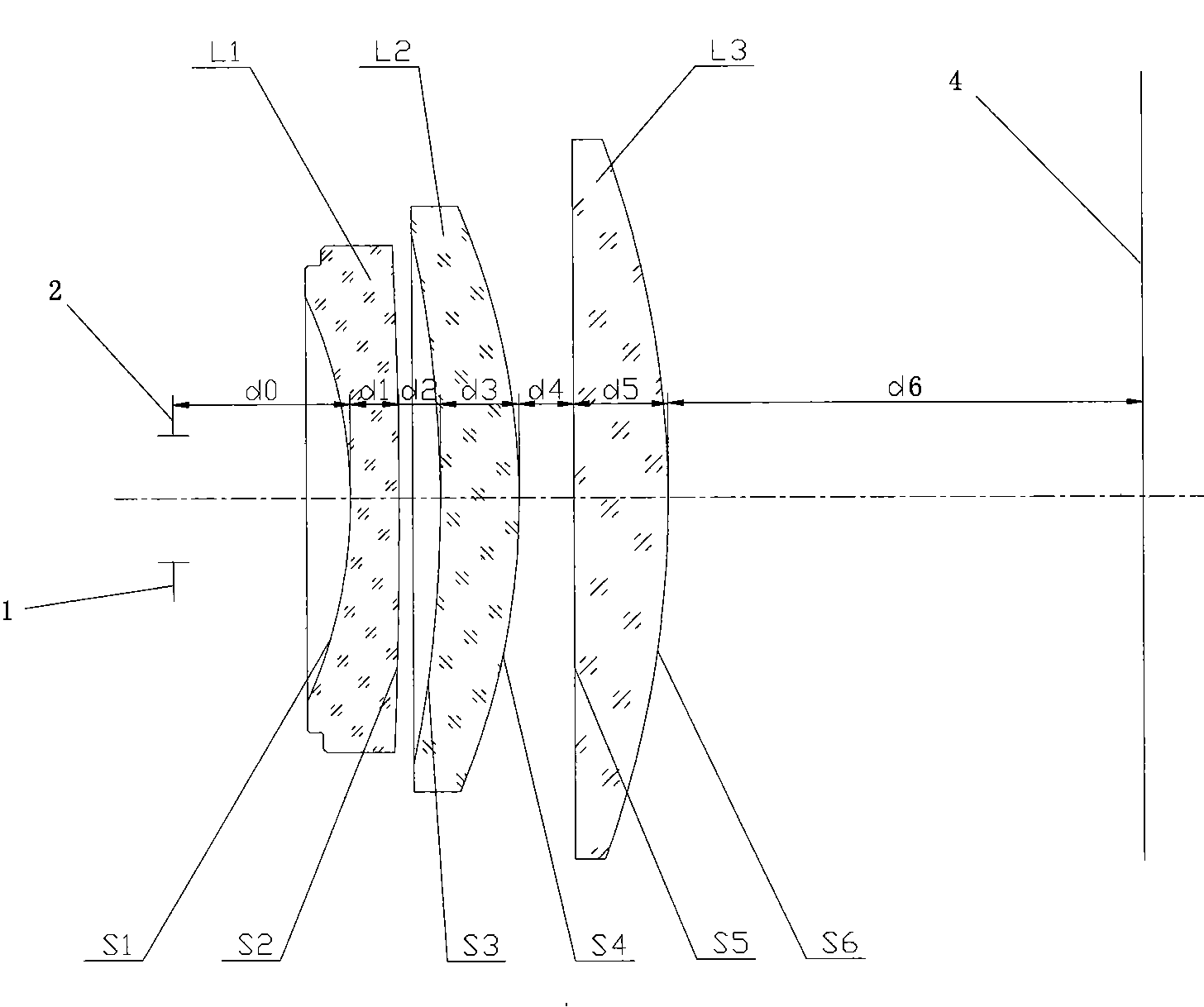

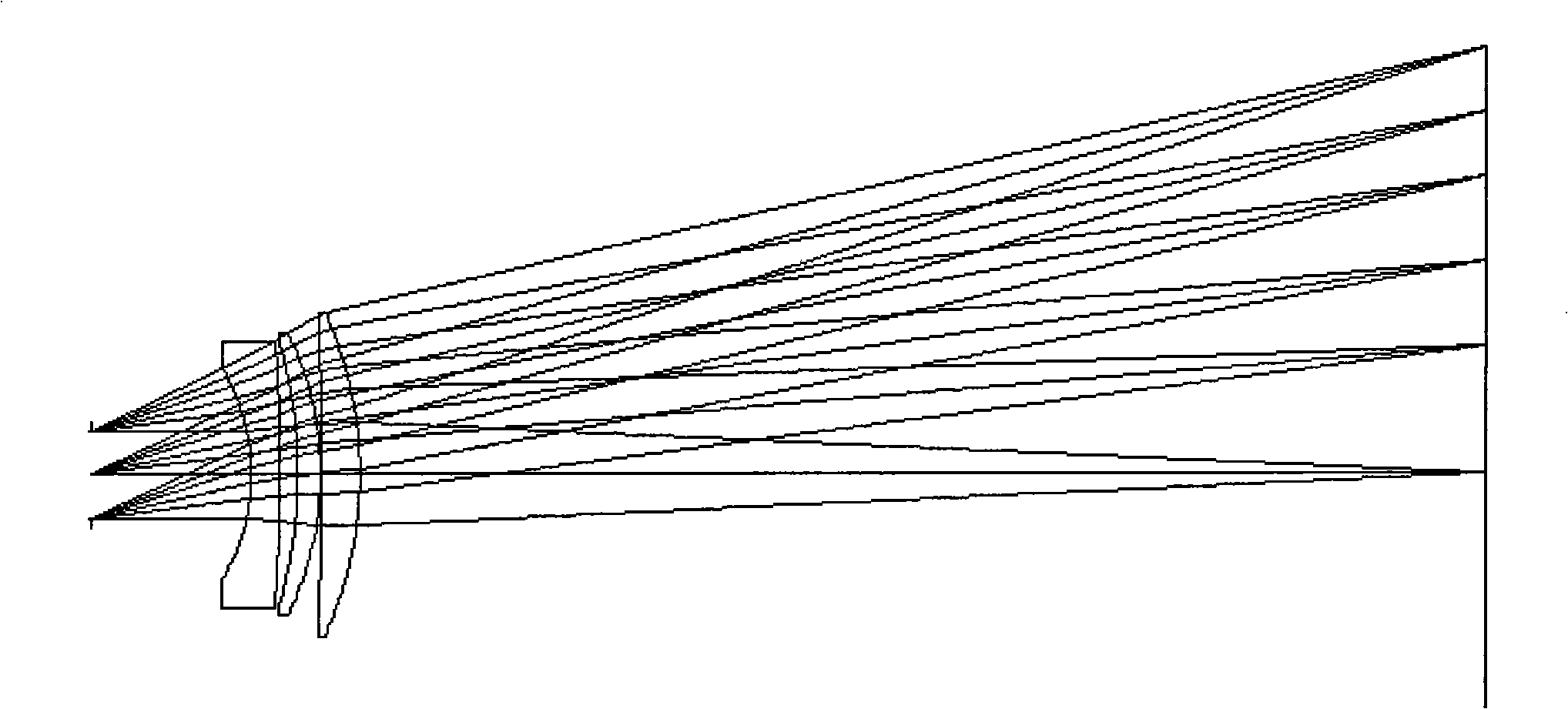

[0026] like figure 2 As shown, the laser application large-aperture fθ optical lens of the present invention is designed with a three-piece "negative-positive-positive" power distribution, including lens groups and diaphragms (vibration mirrors) 1, 2, and the diaphragm (vibration mirror) Mirrors) 1, 2 are located in front of the lens group, and the lens group includes three lenses, which are respectively the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com