Method for installing ceramic lining plates of cyclone dust remover of blast furnace

The technology of a cyclone dust collector and a ceramic lining plate is applied in the direction of a device whose axial direction of the swirl can be reversed, a swirl device, etc., which can solve the problems of high manufacturing cost of the ceramic lining plate, slow construction progress, unfavorable shutdown of production and maintenance, etc. To achieve the effect of reducing maintenance costs, improving production capacity, and good promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below with reference to the accompanying drawings.

[0046] The specific operation steps are as follows:

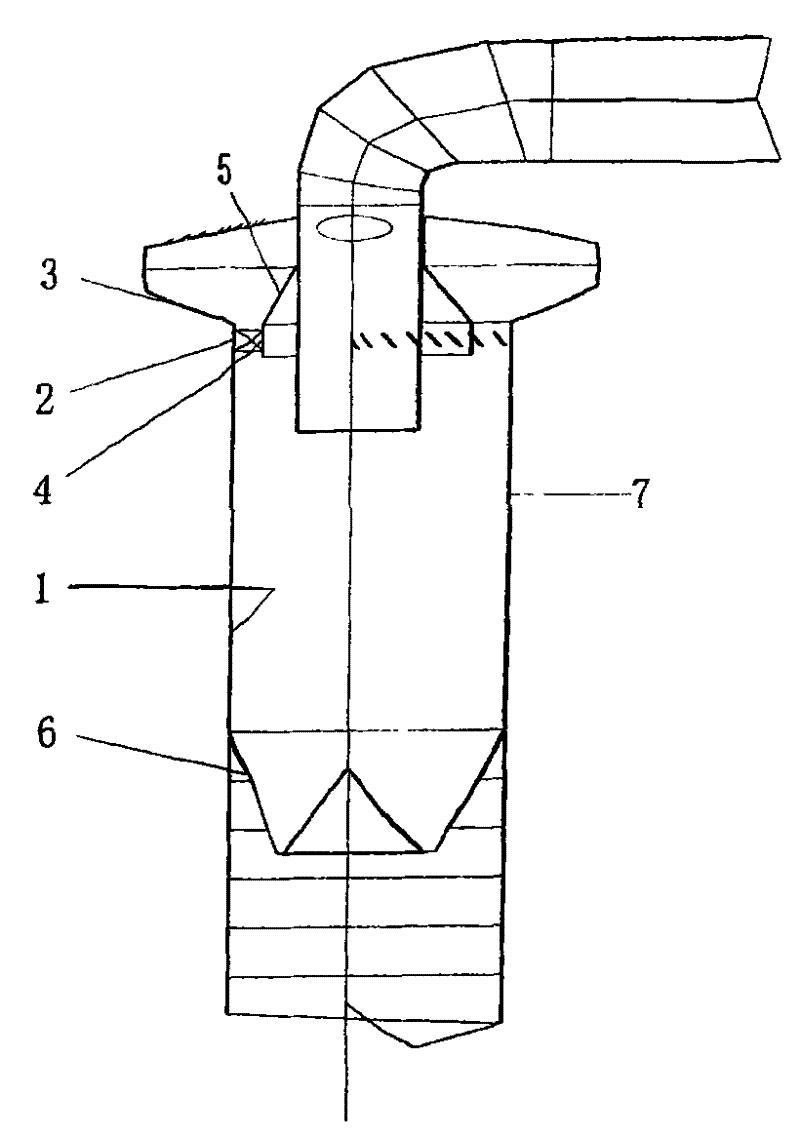

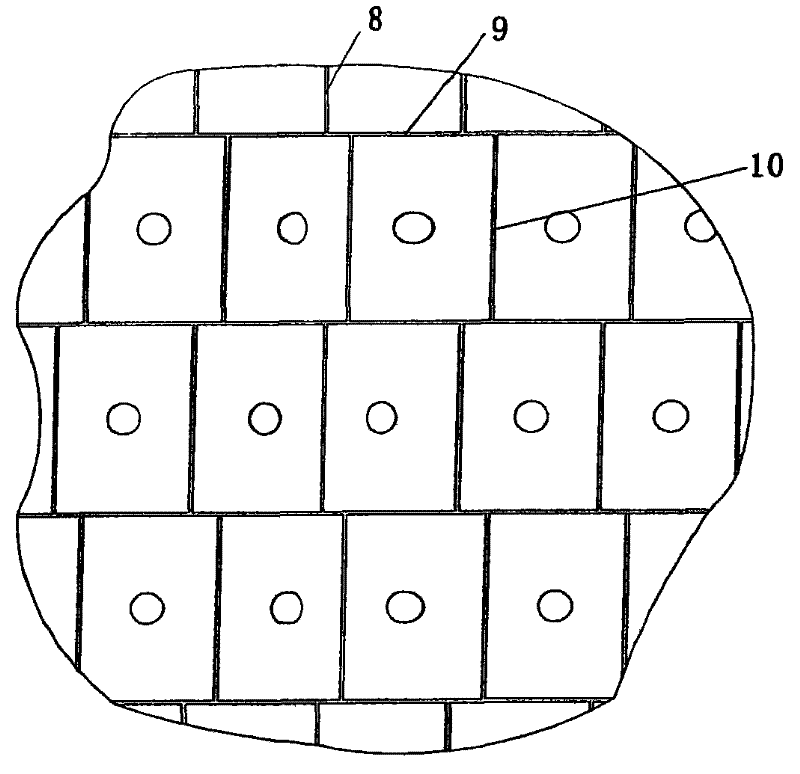

[0047] 1) Select the ceramic lining plate made of zirconia mullite ceramics. The ceramic lining plate has a standard lining plate and a special-shaped lining plate. The specification of the standard lining plate is 180mm×120mm×30mm. The special-shaped ceramic liner and the tapered special-shaped ceramic liner divide the installation position inside the cyclone dust collector into six areas (see figure 1 ),

[0048] 3) Install ceramic liners in area 1,

[0049] Specific steps are as follows:

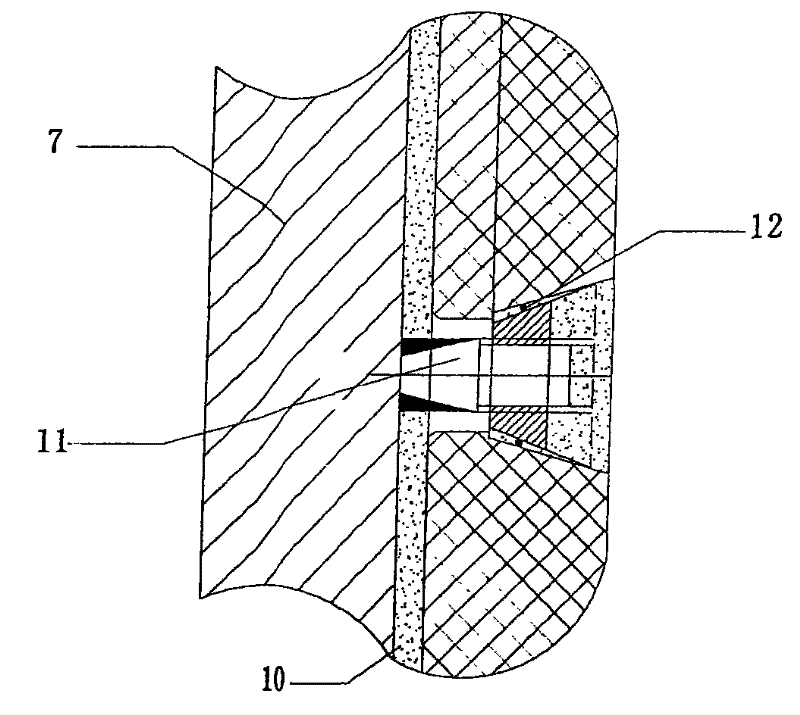

[0050] (1) First use an electric wire grinder or a wire brush to clean up the dust and rust on the inner wall surface of the dust collector housing, and clean the oil stains with acetone.

[0051] (2) Find a horizontal point at the bottom of the inner wall of the shell, use this horizontal point as a reference point, and we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com