Compound sandwich wall and fabrication process and component thereof

A wall and sandwich technology, applied to building components, manufacturing tools, walls, etc., can solve the problems of not being able to make external walls, troublesome construction, high cost, etc., and achieve good thermal insulation performance, good nail holding force, and high earthquake resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

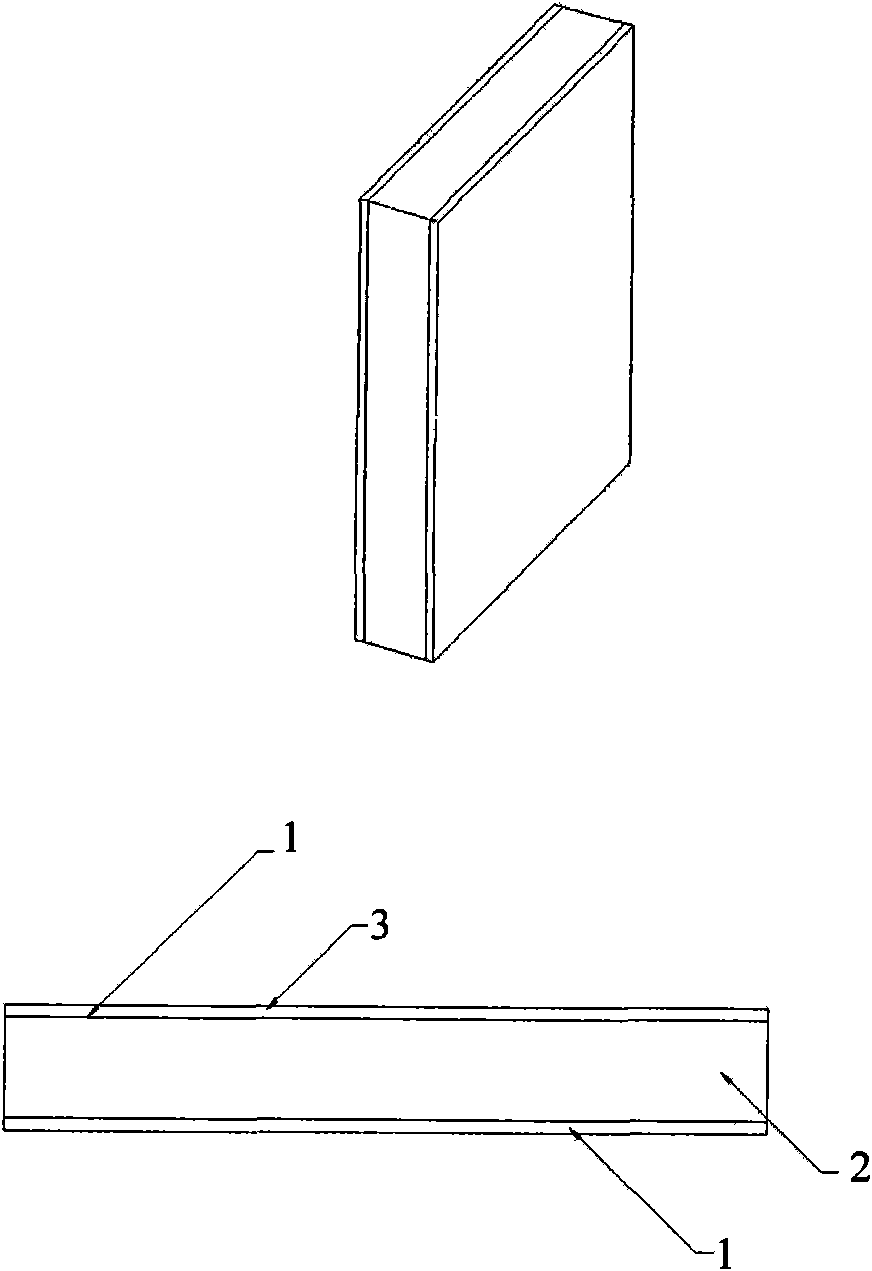

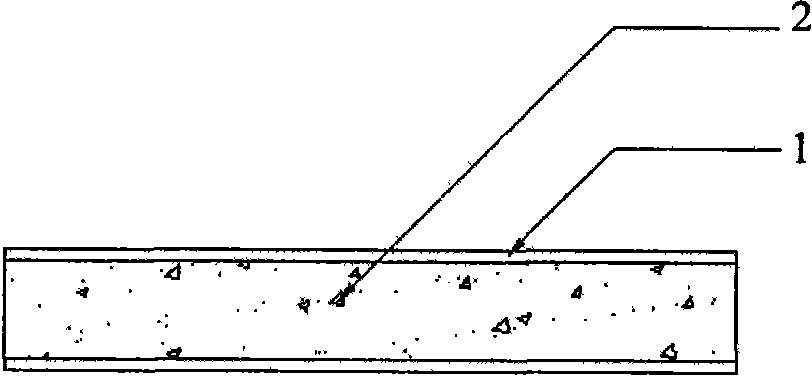

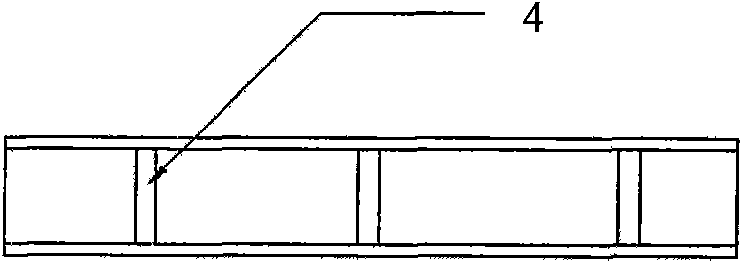

[0031] Combine below Figure 1-Figure 14 The present invention is described in detail:

[0032] The wall body 15 introduced in the present invention is mainly composed of a structural layer 1 and an inorganic sandwich layer 2. The structural layer 1 is composed of two layers of boards. The boards can be wood, bamboo, composite bamboo, bamboo plywood, glued wood, multi-layer plywood, Particleboard, the interlayer is formed between two layers of boards, and the interlayer is mainly filled with inorganic materials such as foam cement, perlite, and vermiculite to form an inorganic sandwich layer 2 . The inner side of the structural layer 1 is coated with lacquer or waterproof paint or waterproof glue to form a waterproof and moisture-proof layer 3 . The surface of the structural layer 1 can be painted, brushed, and decorated (wall wallpaper, cloth, wood and non-wood veneer), as a decorative surface layer, and the structural layer layer can also be directly used as a decorative su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com