Liquid level measuring meter

A liquid level measurement, liquid level technology, applied in the direction of measurement, display of liquid level indicators through pressure measurement, wellbore/well components, etc., can solve problems related to economic effects of development, attenuation of microwave or ultrasonic signals, and high production of heavy oil problems, to achieve the effect of saving labor costs and labor intensity, continuous measurement and monitoring, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

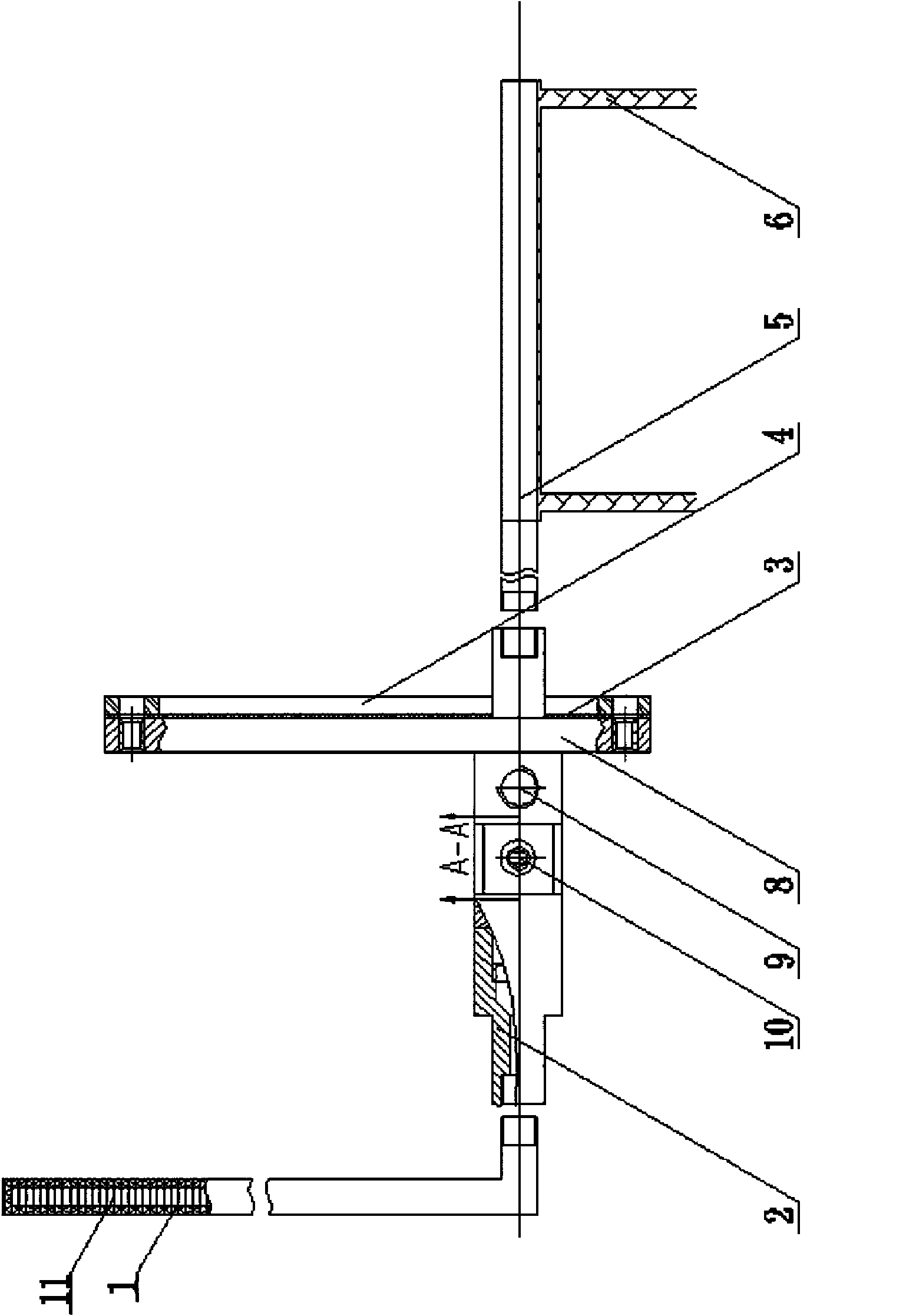

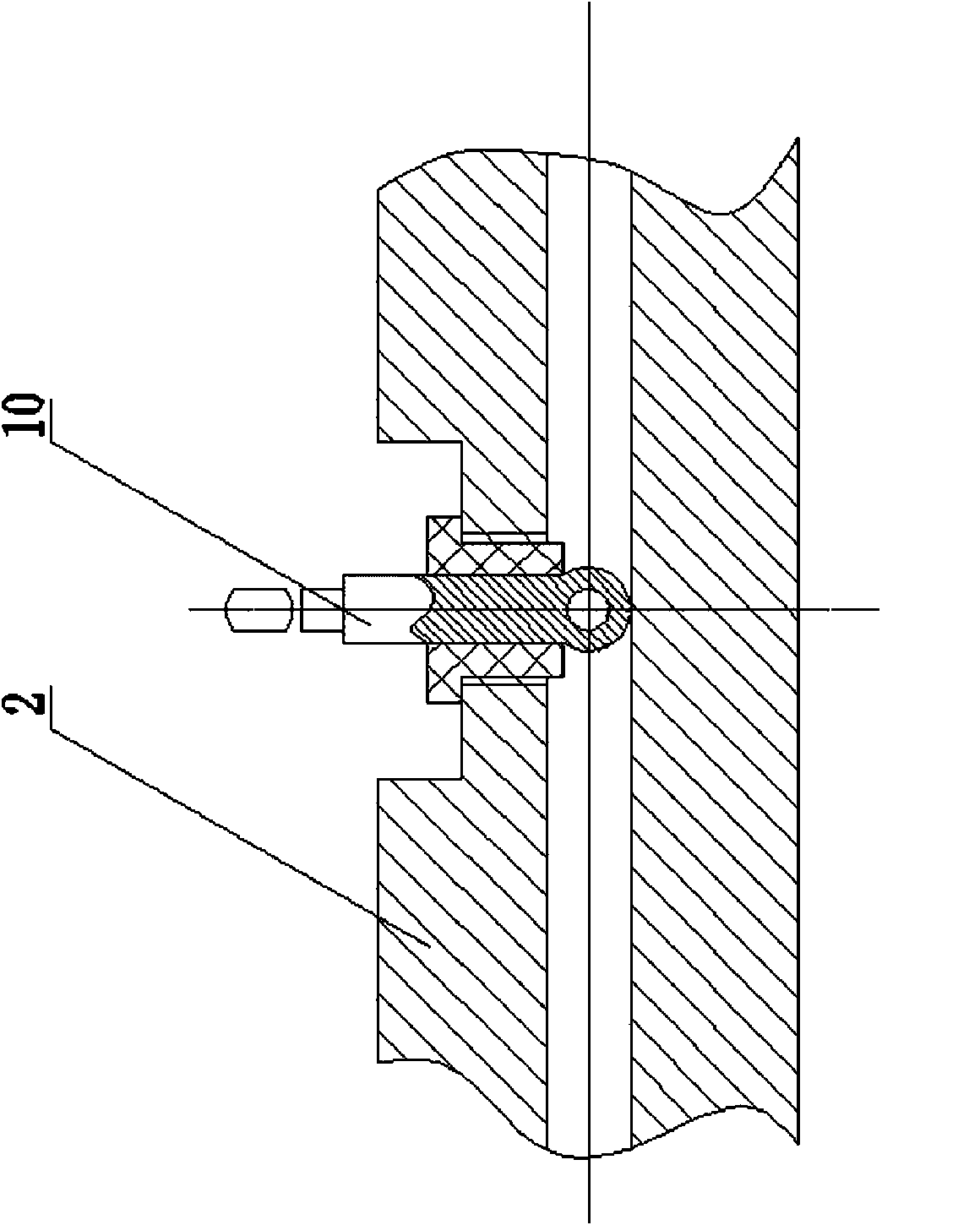

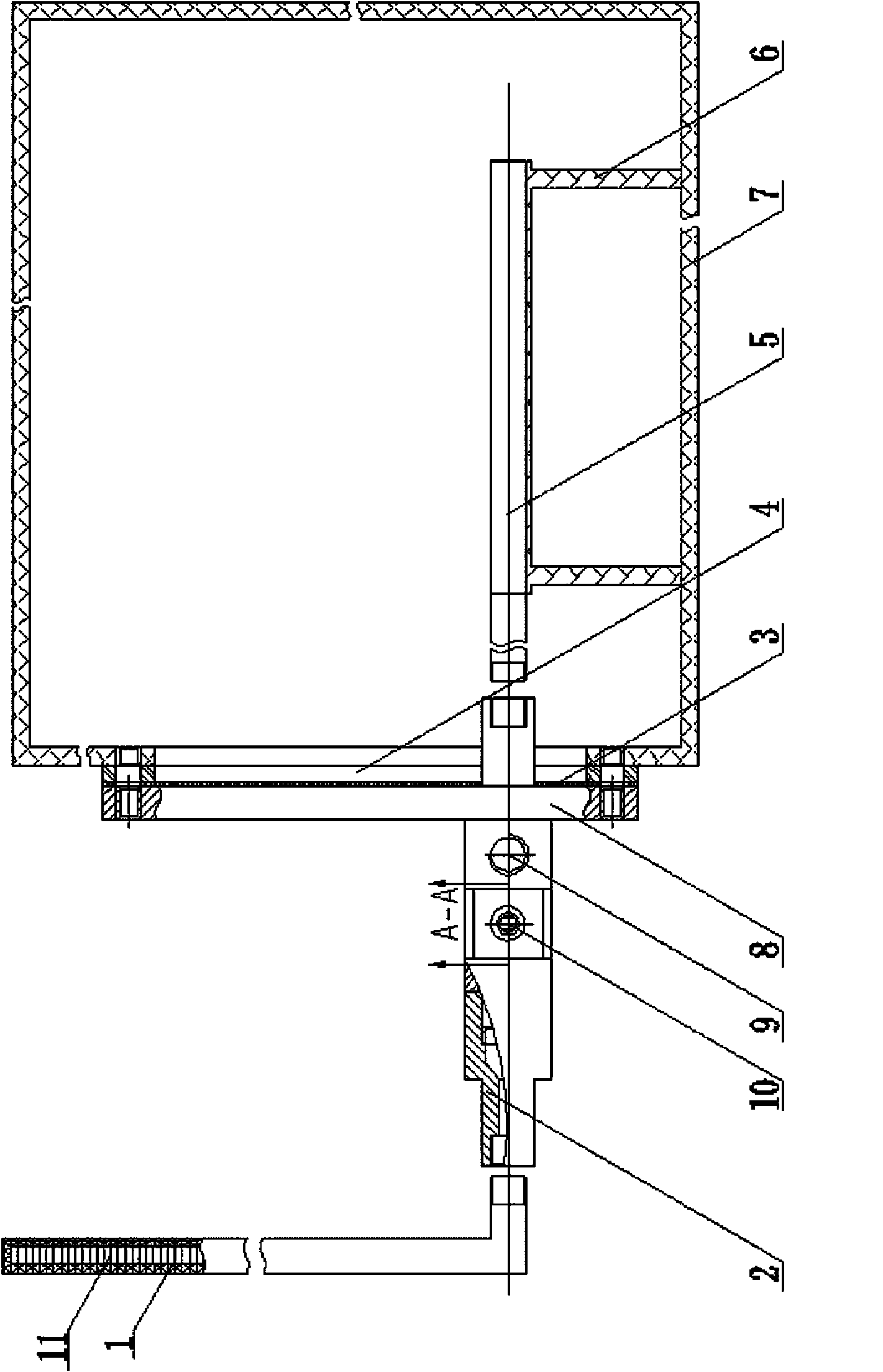

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0018] see Figure 1-Figure 2 , a liquid level measuring instrument, mainly comprising: a pressure-sensitive capsule 5, a pressure-sensitive capsule support frame 6, a pressure introduction tube 2, a liquid level window 1, an annular plate 4, an annular gasket 3, and an opening cover assembly 8 and pressure medium. The annular plate 4 is pre-welded on the opening of the liquid storage tank. Eight uniformly distributed and corresponding threaded holes are formed on the annular plate 4 and the hole cover assembly 8. The annular plate 4 is fixed with a pressure guide tube through screws. 2. The hole cover assembly 8 and the annular gasket 3, the pressure introduction pipe 2 communicate with the liquid level viewing window 1. The pressure-sensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com