Autorotation drive device for automatic lamp inspection machine

A technology of automatic light inspection machine and driving device, which is applied in the direction of measuring device, material analysis by optical means, instrument, etc., can solve the problems of eccentricity or motion instability, affecting detection accuracy, image acquisition effect, etc., and achieves a simple and compact structure. , Improve detection accuracy, good braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

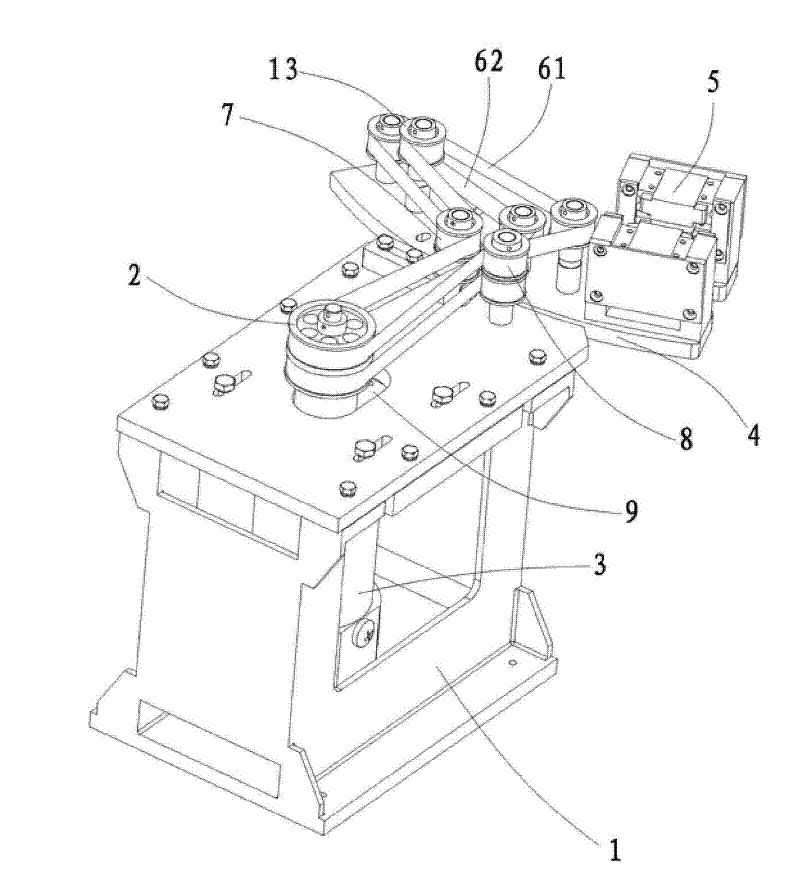

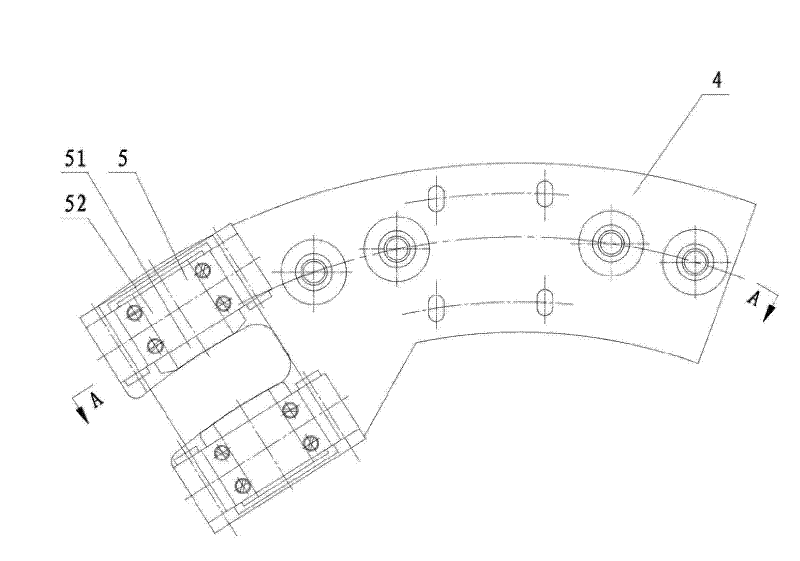

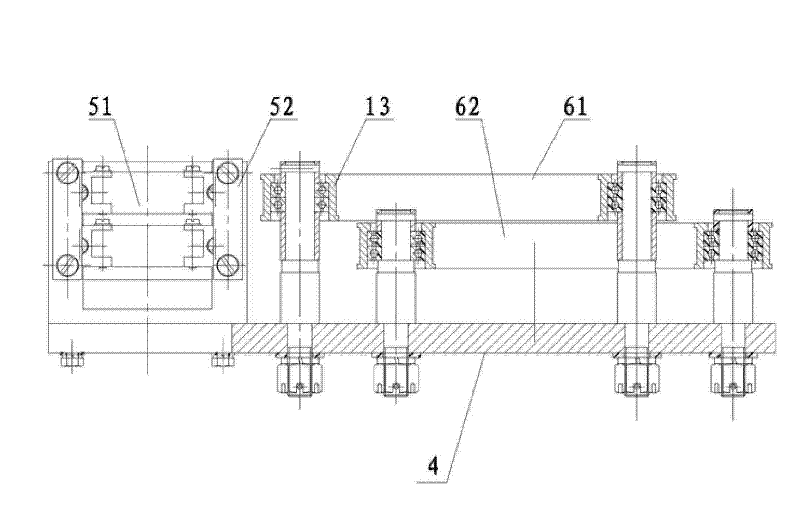

[0024] Such as figure 1 with Figure 5 As shown, the present invention is used in the autorotation driving device of the automatic light inspection machine, which is mainly used to drive the autorotation shaft 11 on the light inspection plate 10, so that it drives the bottle to generate high-speed autorotation. The rotation driving device comprises a drive pulley 2, a rotation drive mechanism 3, an upper transmission belt 61, a lower transmission belt 62, and two sets of transmission pulleys with different heights. The drive pulley 2 is connected to the output end of the rotation drive mechanism 3, and each transmission belt Comprise a pair of driving pulleys 13 with the same height in the wheel set, the upper driving belt 61 is wound around the top of the driving pulley 2 and a higher driving pulley set, and the lower driving belt 62 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com