New application of wall flow type ceramic filter element

A ceramic filter element and new-purpose technology, which is applied in the field of wall-flow ceramic filter elements, can solve the problems of water filter elements such as easy blockage, small flow rate, and inability to filter impurities, and achieve the effects of saving manpower and material resources, large water flow rate, and long replacement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

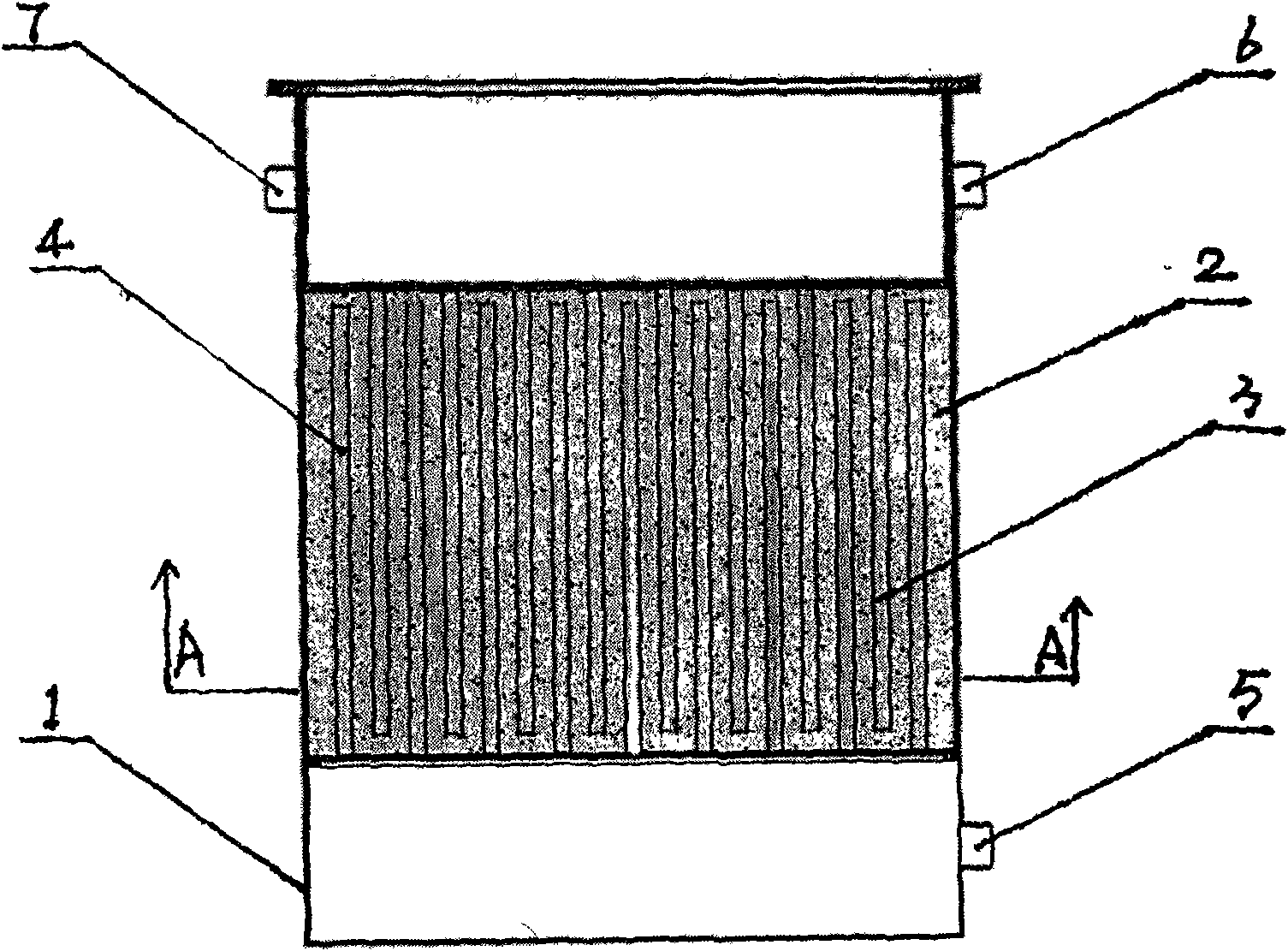

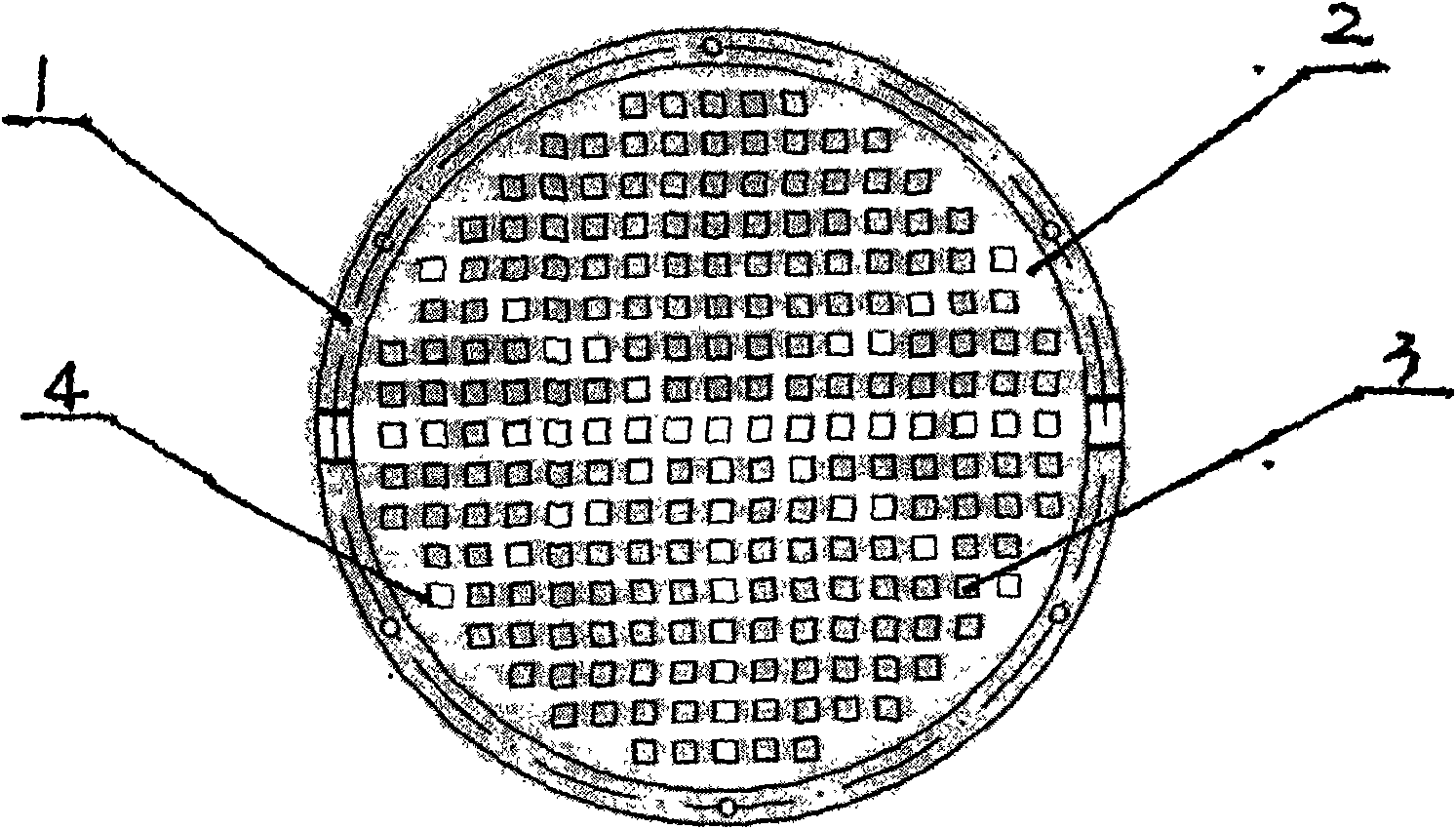

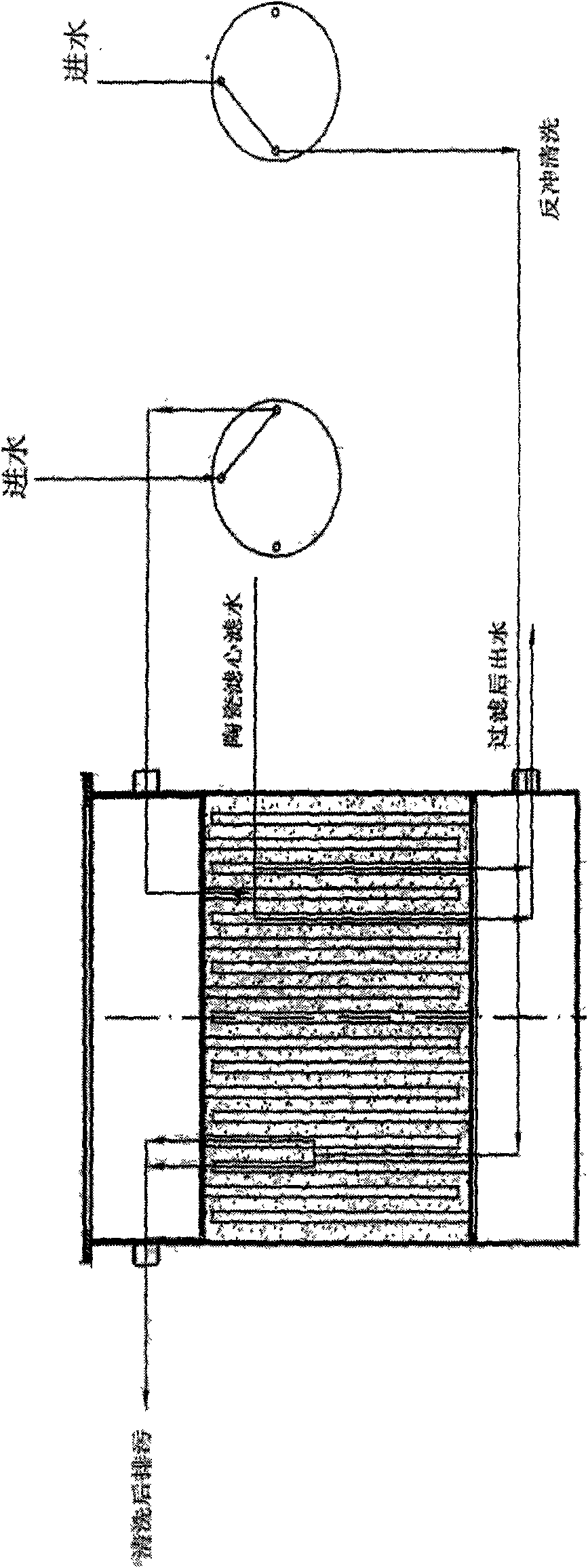

[0010] refer to figure 1 , figure 2 , image 3 , wall-flow water filter ceramic filter element, filter element 2 is made of loose silicon carbide material, the filter element is covered with micropores, the penetration ability is extremely strong, and the overall filter element has the good rigidity of ordinary ceramic products, long service life, filter element 2 Installed in the filter element sleeve 1, the filter element sleeve 1 is connected with the tap water pipe through a two-way valve to form a good water filtration system. One end of the filter element 2 is provided with a plurality of water inlet sink holes 3 arranged in an orderly manner along the axial direction. The other end has a plurality of orderly arranged water outlet sink holes 4 along the axial direction. The water coming in from the water inlet sink holes 3 can quickly penetrate through the micropores on the core body of the filter element 2 to the water outlet holes arranged in an orderly interval. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com