Automobile glass and manufacturing method thereof

A technology for automotive glass and glass, which is applied to vehicle parts, engine sealing, sealing devices, etc., can solve the problems of incomplete cooperation between automotive glass and vehicle body, poor sealing effect of automotive glass, and insufficient firmness. Excellent effect, easy assembly, safe and secure installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical scheme of the present invention is mainly aimed at the prior art, when the car glass is installed on the car body, the fit between the car glass and the car body is not very close, there is a certain tolerance, resulting in poor sealing effect and potential safety hazards. Defects, a new car glass was designed.

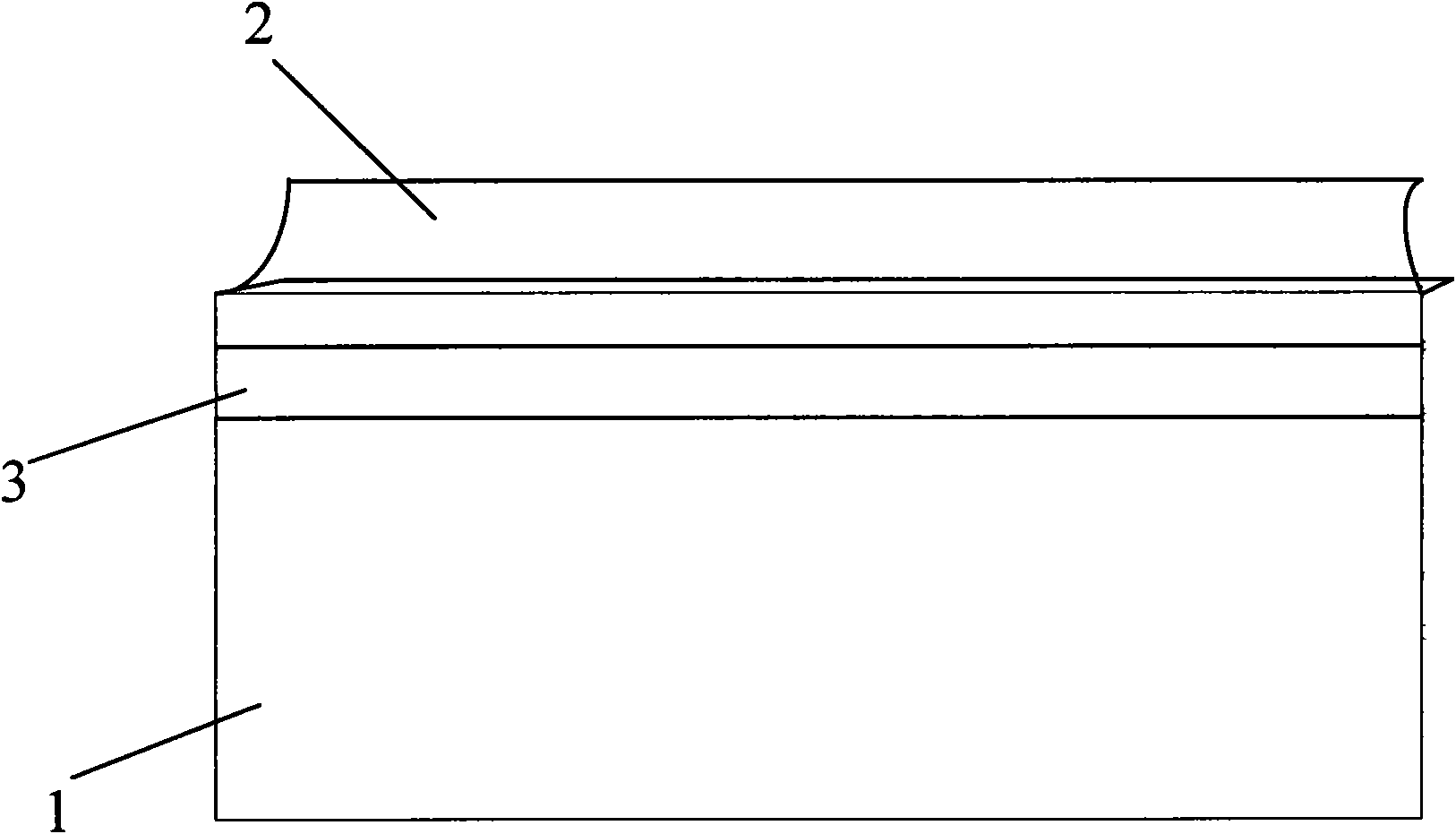

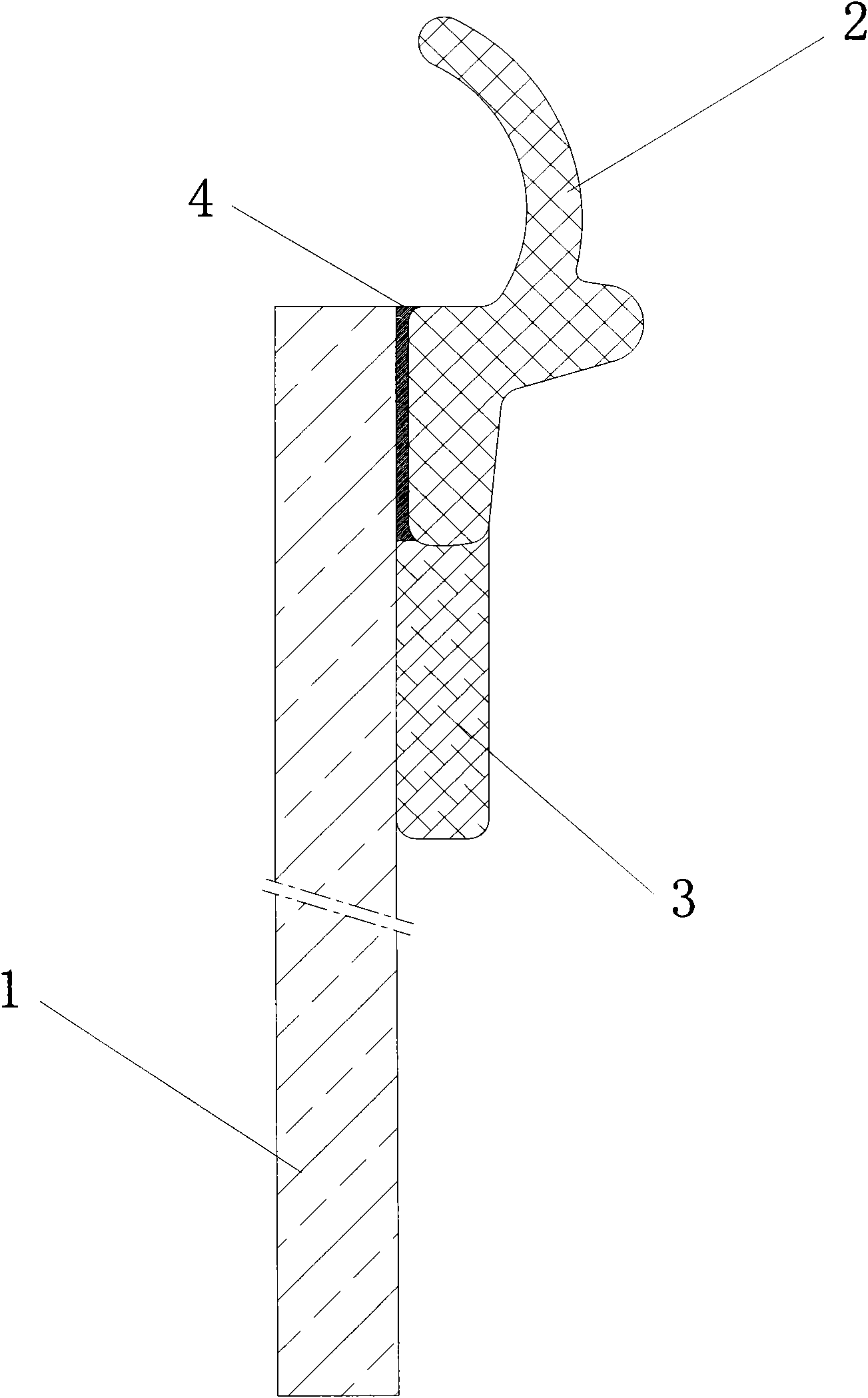

[0020] Such as figure 1 , 2 As shown, in an embodiment of the automotive glass of the present invention, a glass body 1 is included. In general, the glass body 1 may be laminated glass or tempered glass formed by secondary processing from original glass sheets. When using laminated glass, usually two or more layers of glass are glued and pasted together. When tempered glass is selected, it is made by quenching and quenching the glass when it is heated to a temperature close to its softening temperature. Since the surface compressive stress and internal tensile stress of tempered glass are consistent or basically balanced, tempered glass has strong i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com