Double-nut anti-off sucker rod string in thick oil horizontal well

A sucker rod string and sucker rod technology, applied in drill pipes, drilling equipment, earthwork drilling and other directions, can solve problems such as tripping at the rod-string connection, prevent tripping phenomenon, ensure the reliability of anti-dropping, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0018] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

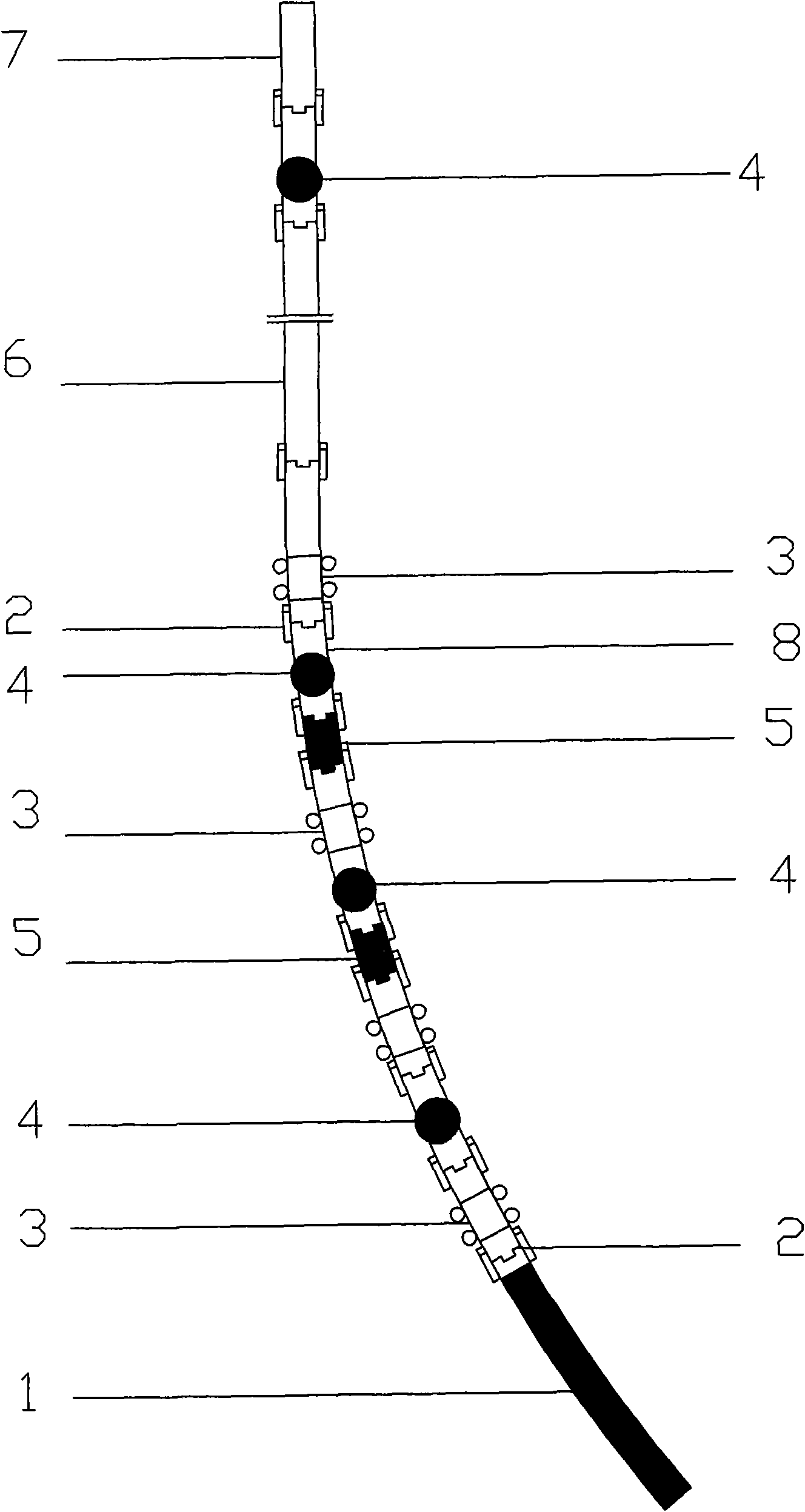

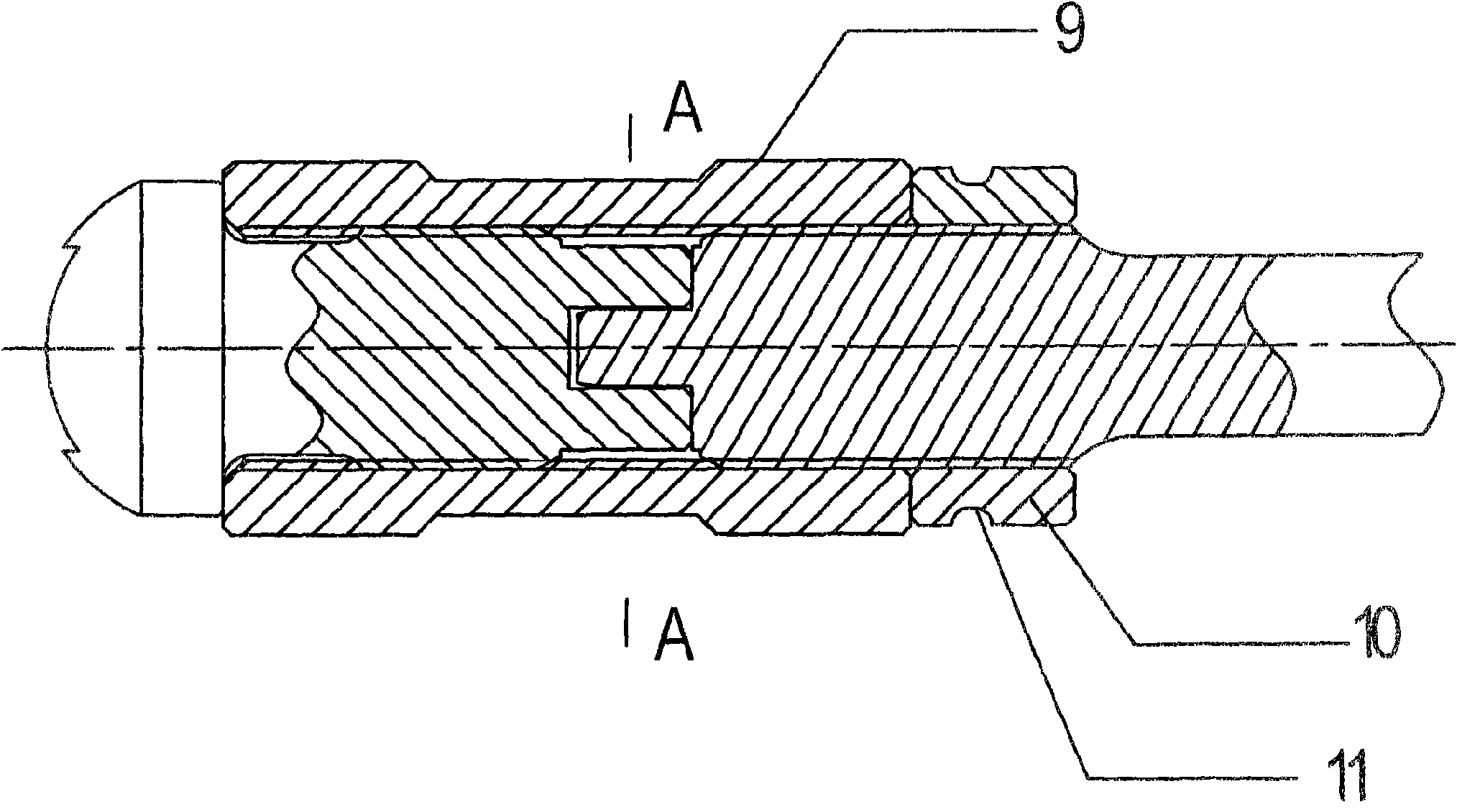

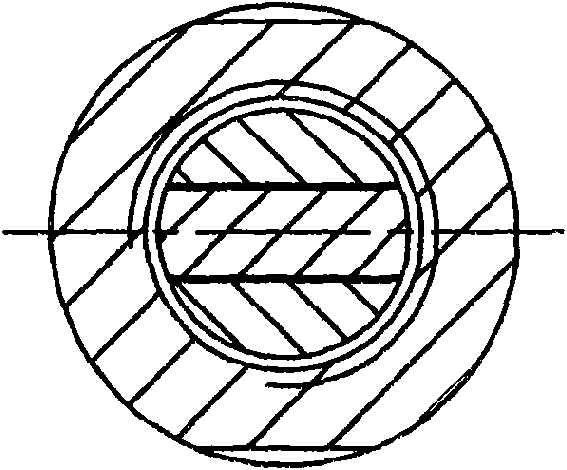

[0019] as attached figure 1 As shown, the heavy oil horizontal well double-nut anti-off sucker rod string includes a polished rod 7, a double-nut sucker rod anti-off device 4, a double-nut anti-off sucker rod 6, no less than one set of anti-off devices and two Nut sucker rod adapter 2; polished rod 7, double nut sucker rod preventer 4, double nut preventer sucker rod 6, not less than one set of anti-loose device and double nut sucker rod adapter 2 from top And the bottom is connected together in sequence; each group of anti-loosening devices includes double-nut anti-loosening sucker rod centralizer 3, double-nut sucker rod anti-loosening device 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com