Ground bored well body structure for gas extraction

A well structure and surface drilling technology, which is applied in gas discharge, surface mining, mining equipment, etc., can solve the problems of drilling blockage, gas casing and screen pipe being easily damaged by shearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

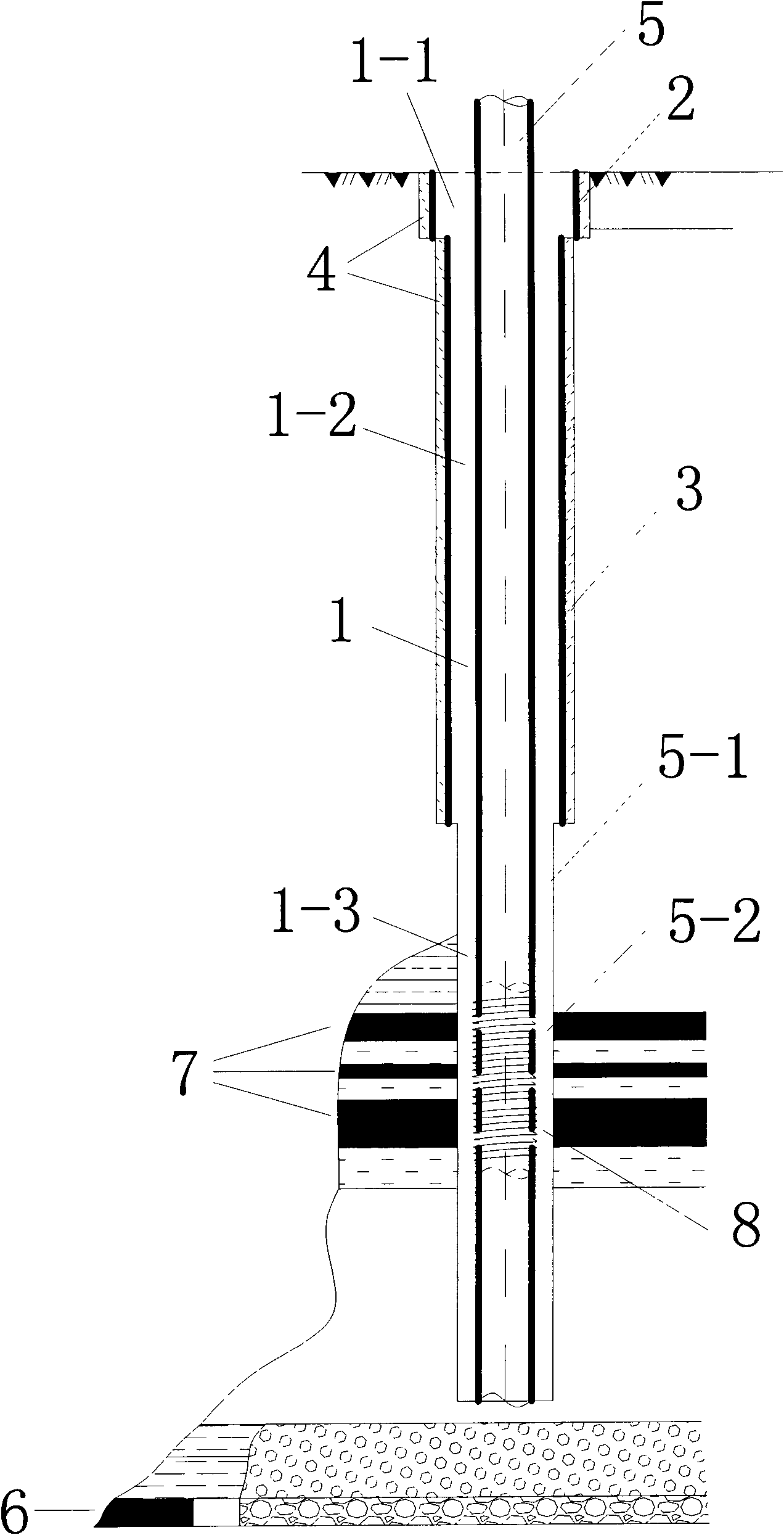

[0017] exist figure 1 Among them, the well body structure is vertical drilling, and the well body is divided into three sections, that is, the surface section 1-1, rock formation section 1-2, and pressure relief and drainage section 1-3 are sequentially arranged from the surface to the bottom of the well. The hole diameter of the borehole decreases sequentially from the surface section 1-1, the rock formation section 1-2, and the pressure relief drainage section 1-3. The surface layer section 1-1 is located from the ground to the bedrock layer, the rock layer section 1-2 is located between the surface layer section 1-1 and the pressure relief extraction section 1-3, and the pressure relief extraction section 1-3 is located on the roof of the upper pressure relief coal seam 7 Between 50-150m above and the mining coal seam 6 of the lower group, the bottom end of the pressure relief extraction section 1-3 is 10-30m away from the roof of the mining coal seam 6 of the lower group. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com